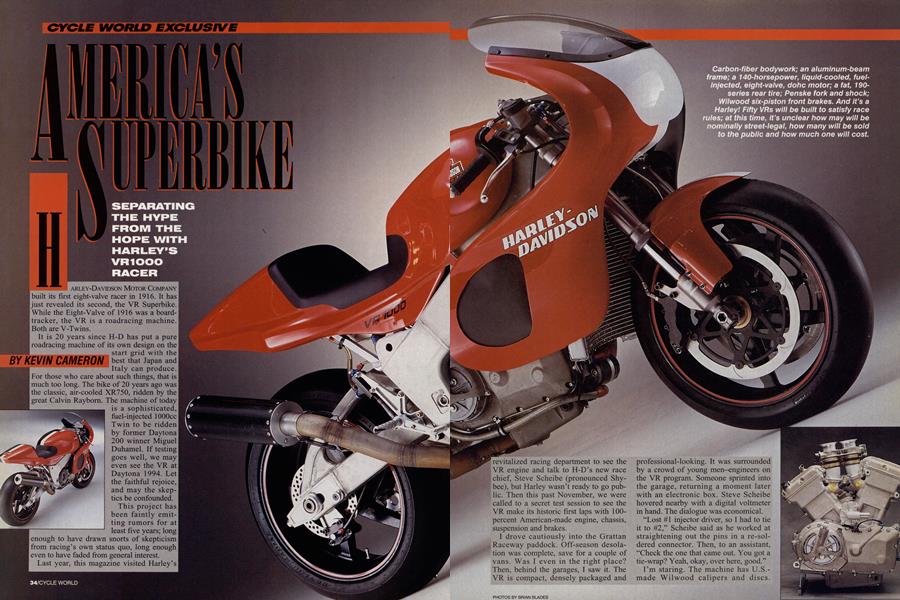

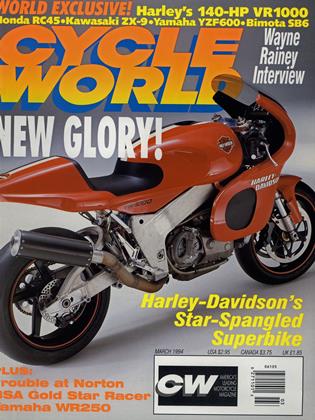

AMERICA'S SUPERBIKE

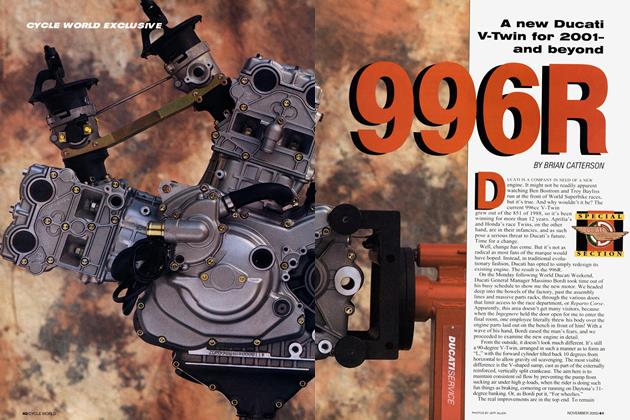

CYCLE WORLD EXCLUSIVE

SEPARATING THE HYPE FROM THE HOPE WITH HARLEY'S VR1000 RACER

HARLEY-DAVIDSON MOTOR COMPANY built its first eight-valve racer in 1916. It has just revealed its second, the VR Superbike. While the Eight-Valve of 1916 was a board-tracker, the VR is a roadracing machine. Both are V-Twins. It is 20 years since H-D has put a pure roadracing machine of its own design on the start grid with the best that Japan and Italy can produce. For those who care about such things, that is much too long. The bike of 20 years ago was the classic, air-cooled XR750, ridden by the great Calvin Rayborn. The machine of today is a sophisticated, fuel-injected 1000cc Twin to be ridden by former Daytona 200 winner Miguel Duhamel. If testing goes well, we may even see the VR at Daytona 1994. Let the faithful rejoice, and may the skeptics be confounded. This project has been faintly emitting rumors for at least five years; long enough to have drawn snorts of skepticism from racing's own status quo, long enough even to have faded from general interest.

Last year, this magazine visited Harley's revitalized racing department to see the VR engine and talk to H-D’s new race chief, Steve Scheibe (pronounced Shybee), but Harley wasn’t ready to go public. Then this past November, we were called to a secret test session to see the VR make its historic first laps with 100percent American-made engine, chassis, suspension and brakes.

KEVIN CAMERON

I drove cautiously into the Grattan Raceway paddock. Off-season desolation was complete, save for a couple of vans. Was I even in the right place? Then, behind the garages, I saw it. The VR is compact, densely packaged and

professional-looking. It was surrounded by a crowd of young men-engineers on the VR program. Someone sprinted into the garage, returning a moment later with an electronic box. Steve Scheibe hovered nearby with a digital voltmeter in hand. The dialogue was economical.

“Lost #1 injector driver, so I had to tie it to #2,” Scheibe said as he worked at straightening out the pins in a re-soldered connector. Then, to an assistant, “Check the one that came out. You got a tie-wrap? Yeah, okay, over here, good.”

I’m staring. The machine has U.S.made Wilwood calipers and discs.

Wilwood is familiar at Indianapolis, as yet unknown on bikes. At the front, a machine-sculptured Penske inverted fork. The twin-beam aluminum chassis is simple, direct-and U.S.-made. The engine is hard to see, buried as it is under chassis beams, pipes, tiny batteries, coolant plumbing. The cylinders sit deep into the case and are part of it. The heads disappear up under the black fuel tank, and I know there is a twin-bore Weber-USA fuelinjection throttle body under there.

They’re ready to start. Scheibe, in leathers, gets on. Pushers take their places. They push, he hits the seat hard, and BLAM, the engine kicks and dies. Another go and it’s running, hammering out that pulse-quickening, stuttery racebike tattoo. Throttle response is immediate as the engine is warmed. Hands reach out to the sides of the oil tank, feeling the warmth come. There is a second sound, too, a rough, mechanical, rockcrusher sound, like two RC30 Hondas with cam-gear clearance. It’s the dry clutch; the sound fades as Scheibe clicks into first. He rides cautiously away, listening. The machine sounds just like a Harley.

An engineer riding a racebike? Certainly. The development engineer knows the questions that this test must answer. Only when he is satisfied with basics like clutch, gearbox and engine internals can he hand over to the impatiently waiting development rider, Scott Zampach.

Prototype testing is a game of starts and stops, and there are plenty now. One by one, the crew diagnoses and fixes the petty problems. As Zampach goes out, Scheibe says, to no one in particular, “It’s a lot faster than the first one, even though it’s 10 horsepower down on most of our dyno engines.” Good response will do that.

“The first one” is the bike previously tested here, with a British Harris chassis and an engine with a less responsive injection control.

Troubles continue, but it’s a pleasure to see the energy and quick thought with which this group of young engineers overcomes them. First it’s voltage spikes, then low system voltage. Wiring is pulled, circuits are traced, and the bike is running again. As dusk comes, the final combination is good, and Zampach gets in many solid laps. The engine sounds big and sharp, the throttle response is good save for a little roughness at the very bottom, and when Zampach gets the back end loose coming onto the pit straight, with the engine note wavering from wheelspin, everyone is grinning, everyone is intensely happy. This is what we’ve all come for.

It’s almost dark as the crew loads up. Zampach, full of adrenaline, eyes shining, praises the turn-in, the braking, the shifting, but wishes there had been time to set the back end up higher, or to try another spring. There are no suspension-action complaints, no engine faults. Scheibe cracks up the crew by asking Zampach, “And how do you feel about the electronics?”

From the head-gasket surfaces downward, the VR is the work of H-D staff engineers. The heads originally were farmed out to Jack Roush’s consulting firm, famous for its NASCAR connections. Steve Scheibe was a Roush employee until two years ago, when he moved to Harley to become racing manager. He is responsible for the changes since then-the redesigned cylinder heads, the lighter castings, the new gearbox, the chassis, the works.

Bore and stroke of this new engine is 98 x 66mm, a ratio of 1.485. This ratio aims at compromise between the needs of combustion (for which a smaller bore and taller, roomier chamber are desirable) and of rpm (for which the shortest possible stroke and big valve area are desirable). The far fringe today are the super-rpm Formula One auto engines, at bore/stroke ratios of 1.7 or 1.8, but which certainly sacrifice combustion efficiency in their wide, super-thin combustion chambers to reach 14-15,000 rpm. The “conservatives” are exemplified by Cosworth, whose HB engine hovers at 1.5 bore/stroke. It makes its power through good combustion, and revs as high as the best materials and design will tolerate. That is likewise the case with the VR, which is aimed at a high piston speed of 4700 feet per minute (developed F-l designs are at 5000, so there’s room to grow). This, with the 66mm stroke, adds up to a peak rpm of 10,850.

The VR’s cylinder angle is 60 degrees, while traditional Harleys have 45. Ducati locked into 90 degrees for its engines in a long-ago era when extra wheelbase was affordable. Ninety degrees gives perfect primary balance, but also makes the engine long. It’s tempting to narrow the vee, gaining two things Ducati has lacked: a short wheelbase and concentration of weight over the front wheel. In the present build, the VR’s

weight is carried 52/48, front/rear. Narrower angles are unusable in a bigbore Twin because of piston interference at BDC. The price of the VR’s 60-degree angle is some primary imbalance, for which Scheibe has provided a rotating balancer that will be included in the next builds. Why not use vibration-free, staggered crankpins, as in Honda’s Hawk VTwin? They break in roadrace use. The VR’s single crankpin

is rugged.

“A lot of things in any engine are dictated, you don’t have much choice”, Scheibe says, referring in one instance to the rod length (at a ratio of nearly 2.2, necessary to keep the piston skirts from touching each other near BDC), in another to valve included angle. It is 32 degrees now. Any narrower and the available room for sparkplug tunnel and tappet guide bores quickly disappears.

Unlike production Harleys, which use traditional forkand-blade roller con-rods, the VR has a pair of plain-bearing Carrillo rods, side-by-side on the single crankpin, and the crank runs in ball bearings. Wiseco-forged three-ring pistons reciprocate in Nikasil-type hard-coated aluminum wetliners, which slide into the upper case/cylinder unit and seal with O-rings. Four half-inch studs jut upward from the surrounding deck. I asked about their hefty size. Scheibe replied, “The gasket makers, Felpro, give a rule-of-thumb that hold-down force equal three times the maximum combustion pressure. So peak pressure is typically a hundred times the compression ratio, that’s 1200 pounds; times the piston area, which is four-pi, roughly 12, so you get maybe seven tons on the piston. Multiply that times three and you get big studs to keep it all sealed.”

Compression ratio at the slightly domed pistons is 12:1. All development running is being done with stainless-steel valves. “Nailhead-style” 39mm intakes and moderately tuliped 33mm exhausts are returned by nested spring pairs (300 pounds open, at .450-inch lift) with titanium retainers. Each of the four chain-driven cams runs in three bearings—there are no overhung lobes-and chilled-iron lobe surfaces drive standard INA 38mm catalog inverted bucket tappets. Nailhead valves-which look like a stick with a disk on the end of it-gave the best flow, and they have a long history. Originally found superior in hemi-head aircraft cylinders by the NACA back in the 1930s, they were rediscovered by Ford while building the SOHC 427 in 1964. Here they are again. The exhausts are two-piece, with Inconel heads on stainless stems. Valve timings are conventional for a four-valve, of the order of 250 degrees duration at one millimeter lift.

Designed from the start for fuel injection, the VR has very large-almost walk-in-intake ports. Scheibe reckons the best compromise between intake velocity and flow loss comes at a low 200 average intake feet per second, and the castings are resolutely sized for this. This is unfamiliar in the still largely carbureted world of bike racing. Most Superbike builders strive constantly to raise intake velocity, the benefits being better mixture formation and higher combustion turbulence. Curiously, German aircraft engines of World War I were also designed to this 200-fps standard! Right now, the VR has dirt-track power characteristics; peak torque comes relatively early, followed by a wide region of nearly constant horsepower.

Weber-USA injection is used “because it’s there, and it works,” says Scheibe. Why reinvent the wheel, why search for fresh problems? The single injectors are aimed at the septum between the intake valve pairs.

Trigger for the ignition is located on the righthand crank end, as windows in a rotating drum. One of the cams likewise carries a position-sensing device that tells the engine control which cycle the crank is on. Twelve millimeter sparkplugs are used, located at the centers of the valve clusters.

Engines with large under-piston volume changes are liable

to pumping losses and, potentially, to so-called wetsumping-the transfer of energy to oil gathering around the crank. In the early VR, the only drainback from the heads was a pair of half-inch holes. Oil was pooling above these, held there in classic H-D fashion by the back-and-forth whooshing of air as the pistons rose and fell. This excess of oil upstairs was great for the camchains, which promptly overheated when a new case design, with much larger case-to-head communication, was tested. This kind of interaction is why testing is so important. Break it and fix it-until it’s right.

To limit the rise and fall of case pressure, the engine’s internal volume is made as large as possible, by linking case, sump, primary case and head volumes, which has worked well on other racing H-Ds.

In the first configuration tested, a compact inverted-magnet-type three-phase alternator was mounted on the crank, right up against the case, with the chain to the camdrive’s intermediate shaft outboard of it. At certain speeds, this extra weight, overhung as it was, produced an oscillating 500-pound force that ate the drive. Now the relation is reversed and parts don’t fail; the camdrive is up against the case and the alternator is outboard.

The chains used are U.S. Tsubaki, which Scheibe reckons to be as good as there is. The company is aggressive, actively seeking difficult applications. Reputedly, their chains are used in the GM/Cadillac Northstar engine. Where are the once-muscular U.S. chain-makers? Presumably satisfied with escalator and hoist business.

Drive from the crank to the clutch is by straight-cut gear. There is no rubber in this drive, which may be the cause of the “rock-crusher” noise. Makers of the clutch, FCC, say dampers are “not necessary for racing.”

When I visited the factory, Scheibe was dissatisfied with the first gearbox. At the Grattan test, a fresh design was used-and it worked without trouble. Why the redesign? “Well, when I calculated the life of first gear, it was less than one minute at full torque,” was the answer. A new shift mechanism has also been designed and installed. A tiny shift drum is carried on a bolted-on trunnion beneath the transmission.

Throughout all this, it’s clear that Scheibe is free to do what has to be done. That’s the only way it can work; a job like this is hard enough by itself, without adding corporate hurdles to be jumped as well. Scheibe is not a chair-warmer at staff meetings, and he is not bogged down in endless reports. His job is to build the VR.

“My boss, Mark Tuttle (head of H-D engineering), has given me a pretty free hand here,” he says.

The initial engine was heavy at over 170 pounds, but Scheibe has carved it down relentlessly with updated castings. The next refinement may be magnesium; alloys now available have properties equivalent to many aluminums, and the weight saving could be another 7 pounds.

Scheibe has criticisms of every part he picks up. He says he is regarded as “negative.” That’s natural, for a working mind always races ahead of reality. No sooner do the new castings come from the foundry, or machined parts from the CNC shop, than there are fresh ideas on how to make them better, in light of the latest tests. Scheibe exudes a sturdy, middleAmerican strength of character, and he’s not mesmerized by the beautiful engineering drawings that pour off the color computer plotters so easily. Like successful racers I have known, the clearest picture of what he wants is the one in his mind.

“I don’t really like drawings all that much. I just make a few notes and stuff them into my desk,” Scheibe says. Hardware wins more races than drawings and reports.

When I visited the race shop last year, I was shown preliminary studies for the chassis that ran in the Grattan test. A few keystrokes brought up a rendering of a chassis under stress, with false colors to illustrate regions of equal deformation.

“Looking at these, you can almost tell which of the Japanese makers are using this (kind of analysis) on their GP chassis,” said Schiebe. He noted a triangular plate, welded atop the junction of main beams, boxing-in the steering head. “If this plate is welded to the outside of the beams...like this,” he pointed to another FEA rendering, “then there is this increase in bending strength during braking.” He pointed to the calculated values. “And some of the GP chassis are welded just this way,” he continued. “Over here you can see how it works with the plate welded to the inner beam edges. Less bending strength.”

The chassis run at Grattan had the top plate welded to the outside edges of the beams.

Skeptical about others’ claims that odd, multi-sided or internally reinforced chassis beams have especially desirable properties, Scheibe ran numerous sections on the computer. An ordinary rectangular beam with rounded comers showed higher bending and torsional stiffness than any of the fancy geometries. To him, this was common sense. That’s just what the Grattan chassis has.

What next? At the end of November, the bike was nearly ready to move from the development stage to the final chassis tuning that can only be done by the end user: Miguel Duhamel. What about engine power? “Mid 140s.” That’s up 12 or more from my visit of a year ago, and the averaged combustion pressure that it reflects (engineers call this the BMEP, for Brake Mean Effective Pressure) is right where the engines of other makers begin their track careers.

Don’t be mesmerized by numbers. When this American team gets to the big dyno in Florida, they will have other advantages. When they call the factory or the suppliers, all of them speak the same language. The people who work on the bike will be the same ones who built it from raw materials; it hasn’t come in a box of mysteries from a far-away place. Development is moving fast. Since I first saw the VR, it has acquired aluminum Nikasil-style cylinder liners, a new gearbox, a new engine-control system, has gained a lot of power and shed a lot of weight. Eiarley-Davidson is evidently serious about writing a new chapter in its corporate history. This is bold, but I believe the company’s trust is well-placed in the team and manager it has. Surely part of the motivation to build the VR is to bring the best of modern race-engine design into Harley-Davidson. As Mark Tuttle has said, it’s important to be aware of all emerging technologies, because you never know what may be required of vehicle manufacturers next.

When will the machine roll onto the start grid? The next hurdle after the prototype is accepted is limited production of the number of machines required for homologation. The number is 50 worldwide. That’s no trivial thing, nor is the preparation of spares and information support for the dealers and others who will want the machine. The Motor Company will want all of that to be done well-and that will take time. The team is shooting for Daytona 1994. If everything goes well, that may be possible. If not Daytona, soon afterwards.

Back in Milwaukee there is a big room in front of the race shop. Over in the comer is The Offlce-the nerve center of racing in the legendary Dick O’Brien’s time and before, maybe back to the days of the very first racing manager, Bill Ottaway. It’s dark now, unoccupied. Scheibe’s desk is out on the floor, with the others, with the computer terminals, the plotter and the parts. I asked about that famous office.

“I keep out of all that,” Scheibe said. “It’s reached a kind of cult status-nothing to do with me. I’m making a little conference room out of it someday.”

Right now, he’s too busy. O

View Full Issue

View Full Issue