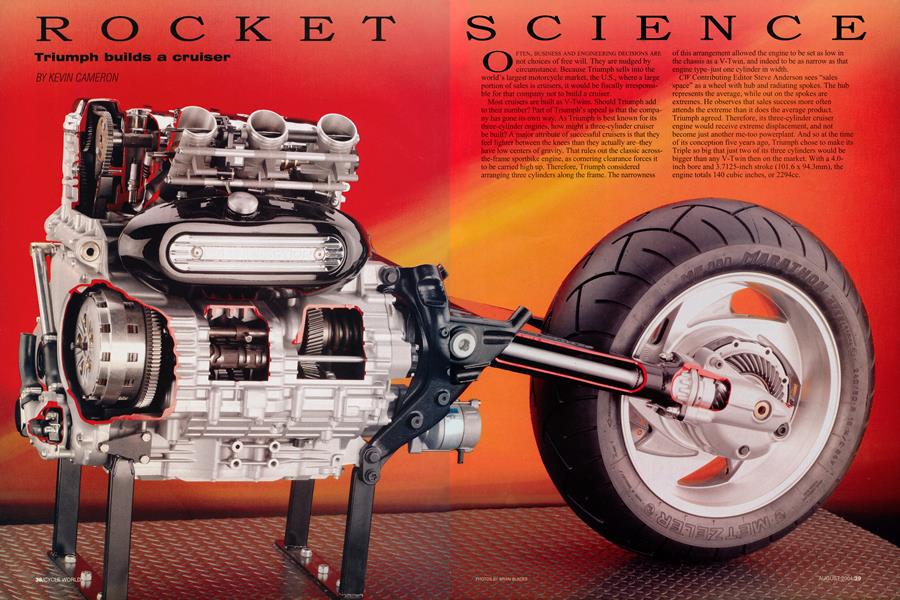

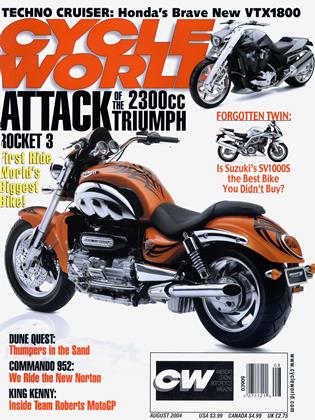

ROCKET SCIENCE

Triumph builds a cruiser

KEVIN CAMERON

OFTEN BUSINESS AND ENGINEERING DECISIONS ARE not choices of free will. They are nudged by circumstance. Because Triumph sells into the world's largest motorcycle market, the U.S., where a large portion of sales is cruisers, it woulb be fiscally irresponsible for that company not to build a cruiser.

compa for its yIinder cruiser esstül cruisers is that they s than they actually are-they ity. That rules out the classic across e sportbike engine, as cornering clearance forces it to be carried high up. Therefore, Triumph considered arranging three cylinders along the frame. The narrowness

V-T -just one cyl 11owed the engine to be set as low in vin. and indeed to be as narrow as that inder in width.

CW Contributing Editor Steve Anderson sees "sales `space" as a wheel with hub and radiating spokes. The hub represents the average, while out on the spokes are extremes. He observes that sales success more often attends the extreme than it does the average product. Triumph agreed. Therefore, its three-cylinder cruiser engine would receive extreme displacement, andn.ot become just another me-too powerplant. And so at the tim.qy~ of its conception five years ago, Triumph chose to make it~ Triple so big that just two of its three cylinders would be bigger than any V-Twin then on the market. With a 4.0inch bore and 3.7125-inch stroke (101.6 x 94,3mm), the engine totals 140 cubic inches, or 2294cc.

Must a cruiser be aircooled? Triumph engineers left that question to purists and wisely employed best modem practice-liquid-cooling with modem coated-aluminum wet liners set into an open-deck block. This keeps all cylinders round and at constant temperature. Sealing is durable. The cylinder block is cast in one piece with the upper crankcase.

A question always asked when any engine’s crank is set along the chassis is, “What about torque reaction? Doesn’t crank inertia tilt the chassis when the throttle is snapped?” Triumph’s design has two features that cancel most of this torque reaction. The wet, multi-plate clutch is driven from the front of the crankshaft and rotates opposite to it, as does also the balance shaft on the engine’s right side. Their “counter-inertia” reduces torque reaction to a small value.

The balance shaft is there to cancel the three-cylinder engine’s natural rocking motion (with crankpins at 120 degrees, the front and rear pistons move 240 degrees out-ofphase with each other). The clutch shaft runs back on the left to a five-speed gearbox. Drive to the rear wheel is by shaft in a unit designed by a specialist gear firm with background in the automotive field.

Horsepower is 140 at 5750 rpm, but cruiser riders prefer rpm, to talk about torque. The Rocket III has plenty of it—147 foot-pounds at 2500 rpm. But cruiser riders mean more by the “T-word” than just twisting force. When they say “torquey,” they mean that no matter at what rpm you twist the throttle, formidable thrust results. The Rocket III succeeds at this in spades-at least 132 of that 147 ft.lbs. is available all the way from 1800 to 6000 rpm.

Consider the predicament of the traditional two-valve cmiser engine, For strong torque at low revs, it must use short valve timing. But with a single intake valve per cylinder, airflow falls behind the pistons’ demand as revs rise. Therefore, torque falls off. If valve timing is extended to stop this torque drop-off, the engine back-pumps charge at low rpm

and loses bottom torque.

With the four valves of the Rocket III, there can be enough flow area even with short valve timing to supply the engine’s airflow needs right across its range. With that short timing, it loses nothing on the bottom. The result is high, nearly constant torque across a wide range.

A major goal was that the bike be easy to ride. Smooth, predictable torque makes constant shifting unnecessary. Smooth throttle control was written into the engine’s software, and the throttle was made more progressive by using a “snail” in the twistgrip. This winds in throttle cable slowly at first, then faster as the throttle opens more. The result is that the rider can take just a sip of power if that’s what is desired. The engine’s three big intake trumpets, throttle butterflies and fuel injectors are on the left, under that gleaming metal “porch.”

Fuel-injection accomplishes more than smooth throttle response-it makes it possible to meet emissions standards in all markets. Exhaust flows from the ports on the right side of the engine into a heat-shielded collector, which carries it to a catalytic converter (the English call it a “cat-box”) located under the swingarm. Two mufflers on the right and one on the left issue from this box. An oxygen sensor holds fuel mixture to the value the catalyst likes best.

A forge-and-twist steel plain-bearing crank follows good automotive practice, and steel con-rods link to three-ring box slipper pistons. Each four-valve combustion chamber has two sparkplugs-necessary in such large bores to provide quick flame travel at even small throttle openings, when the charge is highly diluted. The three intake pipes feed from an unseen plenum under the fuel tank, served by an air filter under the seat.

Our tour of the Triumph factory went beyond the usual assembly line. Engine parts were being machined on a new line of German-designed Heller machines, humming inside their pale-green enclosures. We saw the constant indexing of tool carousels as different tools were spindled for each operation. This is how our world is made.

Assembly lines are much the same everywhere, but it was of special interest to see, near the end of the line, the “P3 check.” Here, the brake, oil and water systems are pressurized for leak test before fluids are drawn into their respective systems by vacuum. Our two Rocket Ills were perfectly sealed machines.

At various points around the factory, employees (this is a young work force) have prepared exhibits that illustrate the stages of parts machining.

The Rocket III engine isn’t breaking a sweat to make its 1 horsepower per cubic inch. Compression ratio is a calm 8.7:1. This is good because lightly stressed engines run a long time. And if you choose to cruise more intensely?

More power will be easy-if you look at things the way I do, you’ve already noticed that a turbocharger would fit nicely in place of that cat-box...

View Full Issue

View Full Issue