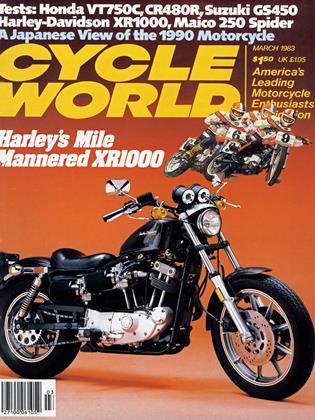

THE 1990 MOTORCYCLE

Would You Believe a 750 Single? How About a TWo-Liter Twin?

Not long ago, I heard a rumor that a Japanese maker was experimenting with a 750cc Single, not with an eye for immediate production, but as a sort of project vehicle. Horsepower was supposed to be around 70, which is reasonably respectable for a 750cc Four. The whole thing sounded a little bizarre: what point could there be in building such a large-displacement Single, and how could anyone possibly get that much power out of it; why would they want to try?

Still, I was intrigued. England’s Panther used to make a 600cc sloper Single, primarily for sidecar work. It’s still fondly remembered by many for its tractability and stump-pulling torque, and the Japanese are making 600cc thumpers again. Maybe there were sensible reasons for seeing what could be done with a really big thumper. So on a recent trip to Japan, I checked it out.

Previous official interviews with the Japanese have taught me that they play their future cards close to the kimono. In such a situation all knowledge of anything would be denied. Last year Shoichiro Irimajiri, Honda R&D brass hat, claimed he knew nothing about the V45 only weeks before it was introduced. So this time no official interviews. This time off-the-cuff chats during lunch, dinner, or at a local pub. No official spokesmen, no super high-ups. Just some lower echelon engineers and planners and outside contractors. Basic ground rules; if I didn’t identify them or their company, they’d talk.

Results?

Yes, a 750cc Single is being developed, with “surprisingly good” horsepower. Also a 1500cc twin-cylinder touring bike that should weigh, complete with fairing and saddlebags, no more than about 440 lb. That’s the goal, anyway.

Incredible? “Revolutionary.” That’s the word that kept popping up as the Kirin beer was slugged down.

“We’ve been hampered in advancing motorcycle technology by something we didn’t even know was a problem,” said one engineer. “Metal. We have to make engines out of metal. Absurd expansion rates. Ridiculous inertial masses reciprocating and rotating. Aluminum in particular is a bad metal to make engines out of. It’s too soft. It expands too much when heated. At least it’s fairly light, compared to iron. But now we have something else. The ideal material to make motors out of. And that opens everything up.”

In very general terms they were talking about composites. A composite is two materials joined together. Currently this means a fiber encased in some sort of plastic. Usually both the fiber and the plastic are derived from petroleum, although not always.

There are composites and there are composites. For instance, the fiber glass used for helmets and fairings is a composite, glass fiber and some sort of resin.

But the super material on which all this speculation is based is many times stronger, more expensive and more difficult to use in mass production. Again speaking generally, it’s known as carbon fiber and it has fiber that’s strings of nearly pure carbon molecules, derived from rayon. In most cases the enclosing material, known as the matrix, is a polyester or epoxy.

Carbon fiber seems to be a truly wonder material; light, with high tensile strength, resistant to fatigue, impact and vibration. But such wonder stuff is very expensive. Carbon fiber costs about $30 a pound when bought in quantity. Also, mass-production techniques, especially for smaller items, are yet to be developed. An earlier interview with Honda R&D revealed that the carbon fiber parts for the NR and NS road racers, simple pieces like brake discs and wheel rims, have a quality rejection rate of about 50 percent: one bad one is discarded for every good one made.

As a result, Irimajiri said, composites remain promising, but nothing more. But during that same visit to Japan, Suzuki’s motorcycle development boss, Etsuo Yokouchi, was much more enthusiastic about composites. “All problems can be solved. They always are. It’s just a matter of time.”

Um, well. Maybe so, maybe not. It’s true that the first computer used vacuum tubes and was big as a house and that in only a few years the transistor, the silicon chip and the printed circuit gave us pocket calculators that outperform the founder of their race, while fitting into your shirt pocket. Research can do wonders.

So, where’s the lifetime battery, the cheap solar power, the mass-produced turbine engine we were promised 20 years ago? Sometimes research only pays the rent for the researchers.

What we’re doing here is speculating, so we’ll assume for the moment that you can solve all problems by throwing test tubes at them.

There has at least been a major committment to doing the work: Nippon Steel Corp., the largest steelmaker in the world, has embarked on a program, in conjunction with Nitetsu Chemical Industry Co., to mass-produce a variety of composites. The plan is to make them cost-competitive with steel before the decade ends. To make the program successful, Nippon Steel has to have assurance large-scale manufacturers will want to buy the composites. And that brings us back to motorcycles—and that big Single. Or, more generally, engines with fewer, larger pistons.

Twenty years ago, big Singles and Twins dominated motorcycling. Compared to today’s multi-cylinder marvels they were low-powered shakers the world has been largely relieved to forget. Those engine designs were ancient even then, essentially prewar, developed in an era when crankshaft bearing and piston ring technology limited engine speed.

Those old motors could have been made to work much better than they ever did, had the British kept up with contemporary developments. The 1983 Suzuki 650 Twin is a perfect example of how well such types of machines can be made to work. But the British did not develop their engines and died, leaving only memories of good low and mid-range power, with comparatively simple maintenance.

C. D. Bohon

The Japanese swept the British away with rpm. They got better reciprocating weight/airflow-capacity ratios by going to lots of little cylinders and developing sophisticated valve technology to keep incoming mixture and outgoing burnt gasses chuffing in and out just as fast as the piston could rise and fall. The result: heavy, complicated engines that rev and breathe like dreams, and scoot motorcycles down the. road like nobody’s business.

As it appears now, the Japanese really didn’t solve fundamental reciprocating internal combustion engine problems. What they did solve were problems relating to the material reciprocating internal combustion engines were made of: metal.

And that brings us back again to that 750cc Single. And composites.

Properties of composites naturally vary with the material used, that is, Kevlar, carbon fiber, Boron, etc. And some are better than others at some things. But fatigue stress is less a problem with carbon fiber than with steel, Aramid dampens vibration better. Carbon fiber has a coefficient of expansion close to that of steel and much less than aluminum. In general composites weigh less than steel, generate less friction, resist heat and of course they do not corrode.

Thus, for the first time in the history of the internal combustion engine, engineers can begin thinking about design without also thinking of the limitations of metal. “This is not just another development of some technique that’s been known since 1901,” one engineer said between slurps of noodle soup. “This will be a revolution. We’re only just beginning to see where it can take us.”

Revolutions don’t happen unless very real problems exist that can’t be solved by conventional methods. Revolutions don’t succeed unless the new method is genuinely better than the old. Composites promise to be genuinely better than metals. But what are the problems they could help solve that metals can’t?

Emissions standards are one. California requires a 1.0 gram per kilometer hydrocarbon exhaust emission standard for motorcycles in 1984. At a recent MIC meeting it was pointed out that this will not likely be the ultimate requirement. Once that standard is achieved 0.50 and even 0.25 gram per kilometer requirements will probably be proposed. With current motorcycle hardware, catalytic converters, with their increased complexity, cost, and customer resistance, seem inevitable.

Fuel economy is another problem. Gasoline, despite the current, temporary oil glut, will inevitably become more expensive. More important, automobiles will become increasingly fuel-efficient. Cars with EPA mileage highway ratings in excess of 70 mpg may become common. According to the EPA some cars get better mileage than some motorcycles. When calculated by a people per mile per mpg basis, a motorcycle ridden solo already comes out very badly compared to an economy car carrying two people. Customer resistance is bound to develop.

Complexity is yet another concern. Surveys have shown that about 90 percent of motorcycle owners do at least some of their own maintenance. Motorcyclists by nature like to tinker with their bikes. They like the satisfaction of knowing their bikes work well because they have made them work well. But the age of the back yard mechanic is largely over. Motorcycle engines are just too complex and sophisticated for the average rider to feel confident he can maintain them. Even if he has that confidence—and the special tools—he may not want to spend the time. The days of the 20 min. valve adjustment are long gone. The problem is even becoming acute for the dealer, who must hire mechanics with the sophisticated knowledge once demanded only of wrenches working on exotic European specialty cars. And he can’t afford to pay the kind of wages a master mechanic who can handle the new engines has a right to demand.

Cost is another problem. Sophisticated engines are expensive to develop and manufacture. They’re expensive to buy. To maintain.

Performance is yet one more problem. More is always better. But the present system—more revs, more cylinders, more valves—demands more and more complexity, all dedicated to exploding more gasoline in a briefer time. And getting the right kind of performance, usable by the customer—low and midrange—may run counter to the necessity of getting more power through more rpm.

These problems came up repeatedly in my conversations with the Japanese. There’s more here than just engineering or the chance to tackle new and exciting projects. The economic health of the engineers, their companies, the motorcycle business as a whole and to some extent Japan depend on people buying motorcycles and that in turn means the companies must make motorcycles people want to buy.

And that brings us back yet once again to the 750cc Single. It could solve all the problems. The Japanese think so, anyway.

Yamaha not long ago funded a study which revealed that the YZ250E, which weighs 216 lb., could have its weight chopped to 110 lb. were it made of composites rather than metal. Weight reductions of that order automatically mean increased performance, dramatically increased performance, in all areas: acceleration, top speed, braking, handling. The potential fuel economy advantages are also enormous.

Although other factors, such as rolling resistance must be factored in to any equation, cutting weight in half, or even only by one third, has got to compute out to less horsepower required. If you can get by with less horsepower you can relax the high tech complexity. You can concentrate on engines that, while they deliver less power, also use less gasoline and emit fewer pollutants. You can think about making an engine simpler, rather than more complex for a change.

And thanks to the wonderful properties of the stuff that makes this light weight possible, you can rethink the requirements of the internal combustion reciprocating engine.

One of the Japanese said they had taken an available engine and installed pistons, wrist and crankpins, and crankshaft made of composites. Peak rpm rose by 1200. Valve gear couldn't handle more. The rpm rose because the inertia loads were less. And because they didn’t have to handle such severe expansion problems, the pistons were designed with much closer tolerances, which resulted in higher compression, less ring wear. Examinations after the tests showed that the greater slipperiness of the composite piston had resulted in less cylinder wear as well.

But that was a Multi, a different sort of design exercise. The Japanese designers are looking for more power, sure. But in our discussions they were also after more efficient use of fuel, cleaner exhaust, a simpler engine.

Enter once again, the composite 750 Single and its logical extension, the 1 500 Twin.

The Single/Twin concept was chosen as being worthy of further investigation because it holds the greatest potential for development. A Four that will rev to 15,000 rpm and do the standing quarter mile in 8 sec. flat has its attractions, sure. But it would extend the present, so to speak, instead of truly being something for the future.

The composite Single/Twin, though, would keep the best of what we have now and give us the above-mentioned advantages, solve the problems that are just over the horizon.

A big Single made of metal is not an ideal motorcycle engine for a number of reasons. In particular, even with counterweights, the dynamic imbalance of the design makes it a shaker. Power is delivered in big hammer blows, which necessitate strong engine mounts and a beefy frame. Ditto drive train components. Hardware mounted to the frame must be isolated from the vibes if it’s not to be shaken to bits.

A big Single made of composites would face similar problems, but they wouldn't be as severe.

Just as we have always thought about engines as metal, so have we considered the various engine configurations in terms of cylinders and displacement.

Force and vibration, for instance. We always talk about a 500cc Single. We know it shakes. We know it needs counterbalancers and/or beefy drivetrain and chassis components.

But. Suppose we don't think displacement. Instead, we think weight. The weight of the piston, the connecting rod, the crankshaft. If we reduce the weight of the piston and rod going up and down, why, yes! We reduce the forces shoving the engine the other way, and that means we need less counterforce and less beef elsewhere. The composite 750 Single’s reciprocating weight would be less than that of a metal 750 Single, so the shakes wouldn't be severe, and conventional counterbalancing, which divides the shakes into vertical and horizontal components, more evenly distributing them, should be able to make it quite smooth. Especially when the vibration damping abilities of composites are considered. A lot more of the shaking would simply be absorbed by the engine and frame and damped before it got to the rider or vital components, which might not have to be isolated from the frame by heavy brackets and rubber bushings. In addition, the inherent strength of composites could handle big power pulses without excessive beefiness.

It’s quite possible, although none of the Japanese we talked to suggested it, that the 750cc Single is merely a concept development engine, an exercise to see what composites do for an engine, and how best to use them, rather than a production prototype itself. The real future may lie in the Twin.

Parallel, horizontal or Vee, no one would say. The only certain claims were that it displaced from 1500 to 2000cc, and that it was to be a touring mount.

A two-liter Twin may sc ind absurd, but we’ve seen how, made of the new materials, it could be quite attractive. But just what type would it be? A parallel Twin doesn’t seem to have much going for it, being little more than a doubled Single, the chief virtue of which is that the two Singles it’s made of are small. However you look at it, the amount' of unbalance in a parallel Twin, with both crankpins in line, is the same as that of a Single of the same displacement. The stroke may be halved, but the reciprocating weight of the motor’s components is twice that of the Single, so everything, er, balances out. Still, parallel Twins have been some of the most successful and long-lived of motorcycle designs. With the virtues of composites added to the balance equation, it could be made into a very superior motorcycle engine, but our guess would be not as a 2000cc machine or even a 1500, but maybe as a lOOOcc.

An opposed Twin has excellent primary balance, but as BMW riders know, there are problems packaging this engine. Of course a flat Twin could be turned 90°, with the cylinders running forward and backwards. With liquid cooling there’s no problem with the back cylinder, and short primary drive to a transmission above the engine could leave lots of room for a long drive shaft. That, in turn, reduces driveshaft effects on the suspension. A bit far-fetched, but the weight would be kept low in the bike and there would be room above the engine for other parts like gas tanks or even storage areas.

That leaves us the V-Twin, which has enjoyed a lot of attention from the Japanese lately. They seem to have done a lot of work on this configuration, and it seems reasonable to suppose they would carry new-found. V-enthusiasm over to their work on the composite engine.

In 90° form it has perfect primary balancing, as the centifugal force of one piston cancels out the inertial force of the other. But the 90° has to contend with unbalanced secondary vibration, which buzzes along at twice engine speed, and, especially in a big V-Twin, can be troublesome. It’s very evident in big Guzzis when you whack open the throttle at idle. Ducati, by turning their engines in-line with the suspension, makes these vibes much less noticeable by allowing the suspension to help absorb them. Speaking of modern, this visit took place before Honda introduced the V-Twins with offset crankpins. They say this can give a less-than-90° Vee the same perfect primary balance and in practice the Honda 750 and 500 Twins are remarkable smooth. Was there a hint of this project during my visit? No.

Even without what seems to be a newer idea than most new ideas, VTwins of less than 90° have proven smooth when carefully designed, so we can’t rule them out. Nor can we forget the cross-frame Vee, as done by Guzzi and Honda, even though than configuration produces a secondary vibration that’s fed into the frame, usually at the front of the cradle, where it’s difficult to absorb or disguise.

So, even with the limits reduced, parallel, cross-frame and opposed Twins in transverse or fore-and-aft layout probably will lose to the classic fore-and-aft upright Vee. The V-Twin has almost all the virtues of the Single, being no wider, not much heavier and—most important for the touring market—having the same wide, flat powerband that lets the bike loaf along all day with plenty of urge on tap. And, despite its huge displacement, it should be, if it’s anything like the modern V-Twins we’ve already seen, very smooth, thanks to the vibration-absorbing capabilities of composites.

Beyond the engine, the engineers and stylists were almost ecstatic about the freedom of design composites would give them for the rest of the bike. The layers of composite material could be vacuumformed into (once the technique is perfected for mass-production) almost any shape desired. What’s more, by aligning the fibers in the material along the lines of stress revealed by computer analysis, those areas in particular need of strength could be made just as strong as required without extra gussetting. That eliminates extra welding, makes manufacturing simpler, and eliminates some ugliness. What was talked of was a monococque frame; heavy and strong where needed, light and weak where strength was unnecessary—all vacuumformed into a single shape in one operation: simple, cheap, clean. More than that, probably blue-skying a bit, one stylist told us, “We can conceive of forming the gas tank, even saddle bag-type storage compartments, as part of the frame and turning out the whole thing in one operation. Think of all the assembly operations eliminated, think of what freedom we would have in styling the bike as a beautiful, integrated whole.”

Indeed, the more you speculate about what composite technology can do for motorcycle, the more the possibilities open up. For us, and for probably all the motorcycle makers in the world but a couple of the Japanese giants, it’s nothing more than dreaming. But the Japanese have big bucks at stake in ensuring they have a saleable product for decades to come, one that meets government regulations and customer and dealer needs. They also have the R&D knowhow and the megabucks required to embark on extensive speculative adventures. They also have the backup in outfits like Nippon Steel, which have an equal stake in ensuring a prosperous future with new products, to make such adventures worthwhile.

When—and whether—we ever see a three-quarter-liter Single or two-liter Twin depends on the research work, and the marketplace.

The research seems to be going well.

Government regulations are getting tighter, which is bad for those of us who like to tune and tinker, good in the sense that new rules create incentive for new designs.

The buying public is the major part of the puzzle. Motorcycle sales are in a slump. Traditionally when bikes aren’t selling the factories hit us with exotica, hoping to entice us to buy. But if sagging sales aren’t the result of the worldwide recession, the rules may change and there may no longer be a justification for the huge investment in time and money needed to produce the composite motorcycle.

A Yamaha marketing man commented during one of my previous visits to Japan that “We’ve tried everything we can to entice young riders. We just can’t seem to get them.”

During this trip the same question arose. One outside contractor, himself a died-in-the-leather biker, said “We’re in a baby boom business. Chance had it that our companies developed mass-production motorcycle capacities just as the postwar American baby-boom kids were becoming teenagers in an affluent era. They took to motorcycles as a new recreation by the millions and we built millions of motorcycles, each better than the last model because competition was fierce. Then the European and Japanese baby booms came of age and they bought more millions. We thought it would never end. But if you look at population statistics you’ll see the populations of America, Europe, and especially Japan are aging. Young riders aren’t entering the market in the numbers they used to because there aren’t as many of them as there used to be. There’ll be fewer in the future. Inevitably the motorcycle market will grow smaller. It’s not going to pay to expend vast sums of money to develop new models for a decade away market which may be so small even one manufacturer might have a hard time breaking even.”

Was he hinting that the red hot development work going on now might remain mere development work because there may be no future market for it? Perhaps. But we suspect the composite motorcycle, the big big Single and the big big Twin, will come to pass. Composite technology will be developed; it has too many attractions, in automobiles, for example, not to be. Once the technology is in place, motorcycle makers will use it, and they will use it in the best possible ways for their ends: cheap to make, simple to maintain, clean-burning, tractable, light motorcycle engines. The Single. The Twin. They’ll be here. Sooner or later.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontFor Adults Only

March 1983 By Allan Girdler -

Letters

LettersLetters

March 1983 -

Book Review

Book ReviewVincent Vee Twins

March 1983 By AG -

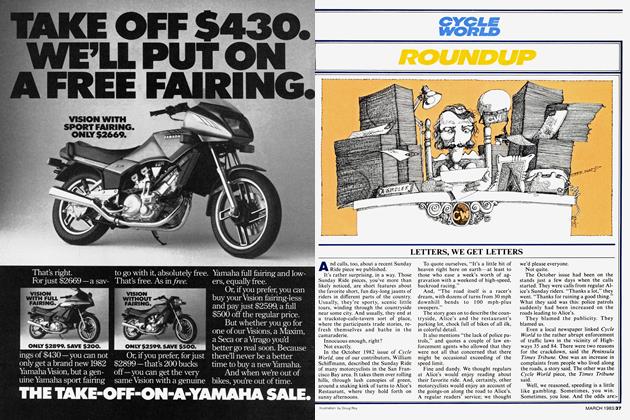

Departments

DepartmentsRoundup

March 1983 By James F. Quinn -

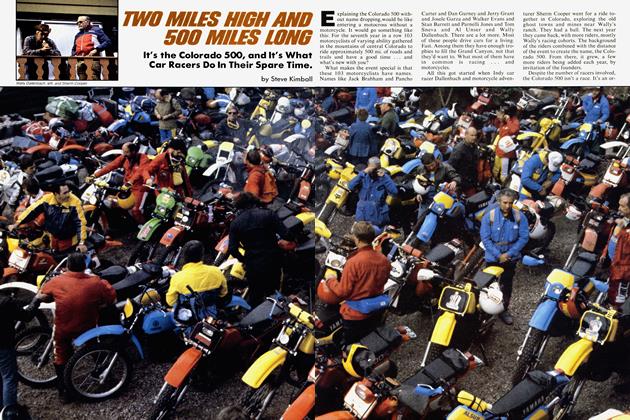

Features

FeaturesTwo Miles High And 500 Miles Long

March 1983 By Steve Kimball -

Technical

TechnicalSouping the 650 Seca

March 1983 By John Ulrich