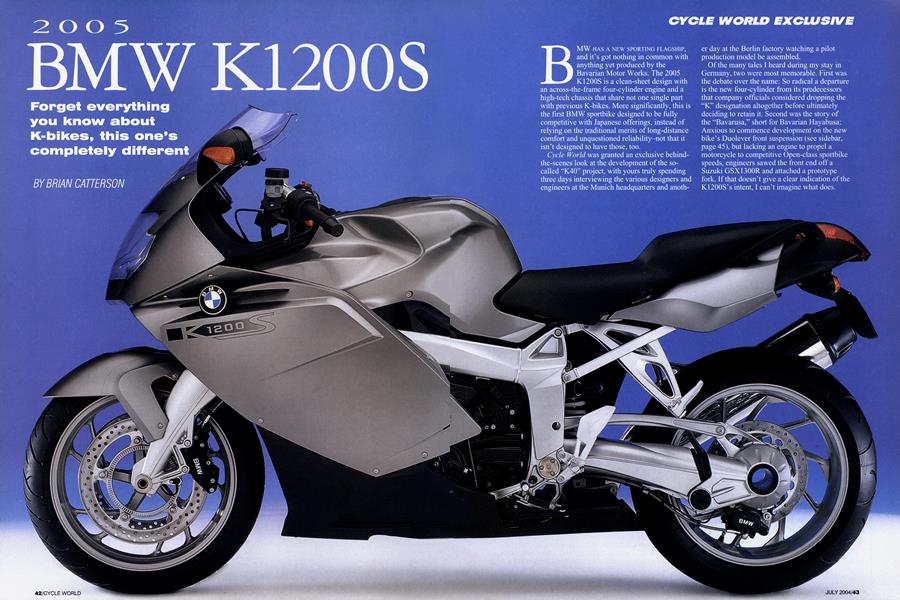

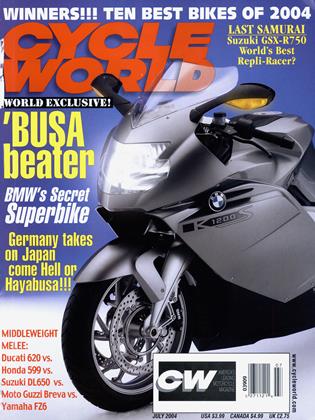

2005 BMWK1200S

Forget everything you know about K-bikes, this one's completely different

BRIAN CATTERSON

CYCLE WORLD EXCLUSIVE

BMW HAS A NEW SPORTING FLAGSHIP, and it’s got nothing in common with anything yet produced by the Bavarian Motor Works. The 2005 K1200S is a clean-sheet design with an across-the-frame four-cylinder engine and a high-tech chassis that share not one single part with previous K-bikes. More significantly, this is the first BMW sportbike designed to be fully competitive with Japanese offerings, instead of relying on the traditional merits of long-distance comfort and unquestioned reliability-not that it isn’t designed to have those, too. Cycle World was granted an exclusive behind-the-scenes look at the development of the so-called “K40” project, with yours truly spending three days interviewing the various designers and engineers at the Munich headquarters and anoth-

er day at the Berlin factory watching a pilot production model be assembled.

Of the many tales I heard during my stay in Germany, two were most memorable. First was the debate over the name: So radical a departure is the new four-cylinder from its predecessors that company officials considered dropping the “K” designation altogether before ultimately deciding to retain it. Second was the story of the “Bavarusa,” short for Bavarian Hayabusa: Anxious to commence development on the new bike’s Duolever front suspension (see sidebar, page 45), but lacking an engine to propel a motorcycle to competitive Open-class sportbike speeds, engineers sawed the front end off a Suzuki GSX1300R and attached a prototype fork. If that doesn’t give a clear indication of the K1200S’s intent, I can’t imagine what does.

But that’s putting the cart before the horse, as it were. Given the never-ending discussions that transpire at any major motorcycle manufacturer, it’s difficult to pinpoint the exact date that the K40 project began. The consensus is that it got its start five years ago, in early 1999.

Dr. Herbert Diess, Managing Director of BMW Motorrad, said that while the K1200S was envisioned as the sportiest BMW motorcycle ever, “It’s a sportbike, not a superbike.

We have no plans to race it.”

That sentiment was echoed countless times over the following days, not least by Dr. Markus Braunsperger, head of R&D. Asked to cite which, if any, competitors’ bikes were targeted as reference models, he replied, “The Honda CBR1100XX was the focus. It’s passenger-oriented and very usable with some wind protection. With the Hayabusa, the aerodynamics dictate the look, and the Kawasaki ZX12R looks like a supersport bike, but it’s definitely not a supersport bike!”

The original K100 was a tremendous step forward when it was introduced in 1985 (see sidebar, page 51), what with its fuel-injected, laid-down longitudinal four-cylinder engine. And while the so-called “Flying Brick” was developed as far as it could be over the following two decades, technology ultimately left it behind-especially if you’re going after ’Busas and Blackbirds.

Explained Franz Berkmann, K-bike Project Leader, “We studied our existing four-cylinder engine, but decided it couldn’t make enough power. The airbox would have to be outside the bike, and the exhaust is too short, and unequal in length.”

Added K-Series Director Markus Porschner, “The Flying Brick was unique, but we had some goals that made it necessary to view other options. It’s one of the most challenging topics, to decide where we want to go. It’s good if you ask many questions at the beginning.”

And ask questions they did, judging by the notebook that Wolfgang Nehse, Director of Powertrain Development, showed me. Chock-full of engine concepts dating back as far as 1996, it included various flat, inline and vee configurations with as many as six cylinders. Ultimately, though, it was decided that a transverse inline-Four was the optimum design, conventional in concept if not in execution.

“A new engine is very exciting for us,” exclaimed Nehse, who previously worked on the McLaren Fl supercar. “We don’t get to do this every day.”

The main goals of the engine program were reduced weight, increased power and decreased fuel consumption, but no less important was packaging, how the engine would fit into the chassis. To hear Porschner tell it, “K” originally stood for Kompact, but the new engine is decidedly more so. Its designers claim it’s smaller than all contemporary Openclassers, closer to the size of a 600, and barely 2 inches wider than a Ducati V-Twin.

Though some facets of the engine’s design were still shrouded in secrecy during my visit, others were revealed, and a few were readily apparent. Most obvious is the angle of the cylinder block, tilted so far from vertical that it’s closer to horizontal. On a pure sportbike, this would have the undesirable effect of moving the crankshaft center far from the front tire’s contact patch, but on a long-wheelbase streetbike such as this, that’s not as much of a concern. What it does achieve is keeping the frame narrow between the rider’s legs as the main spars pass directly over the cylinder head instead of splaying around it.

The ribbed crankcase is split horizontally, with the plated aluminum cylinders cast integrally with the top case half and all ancillary components stacked atop that. A dry-sump design, the engine has its oil tank and filler cap located under the rider’s seat and an oil-level sight tube running down the right side. The advantages here are reduced crank windage and a low center of gravity, some 60mm (2.4 inches) below that of comparable sportbikes if you believe the engineers. Solid-mounted in the frame, the engine is undoubtedly counterbalanced.

The forward tilt of the camchain tunnel suggests that only the exhaust cam is chain-driven, while the bulge between the numbers 3 and 4 cylinders hints that the two shafts are joined by a pair of gears, thus rotate in opposite directions. The intake cam in turn drives the water pump off its left end, with coolant flowing through the cylinder heads first instead of up from the block as on other liquid-cooled motorcycles. Short coolant hoses, perhaps 6 inches long, connect the engine to the traditionally located radiator, while an oil radiator below the headlight provides additional cooling. The cam lobes open the 16 valves via small finger followers, which save space over traditional bucket tappets by allowing higher valve speeds and greater lift with no need to increase tappet diameter. They’re also more stable because there’s no possibility of the cam lobe rocking the tappet. Though valve lash is set by shims, the service interval is said to be many thousands of miles.

According to Nehse, extensive bench-testing has shown the new engine to be mechanically reliable well beyond its 11,000-rpm redline-one engine was said to have survived being accidentally spun to 20,000 rpm for a full hour when a technician failed to consider the reduction ratio! I watched one such bench-test, in which an electric motor turned the crank at high revs and a laser tracked valve lift and speed to ensure there was no float.

A downdraft fuel-injection system inhales through the airbox directly above it, which is in turn fed by a pair of snorkels at the upper comers of the radiator opening. Though it’s technically a ram-air system, Nehse downplayed the importance of this, saying that his testing revealed the increased pressure only boosted power by 3 percent at top speed.

The hydraulically actuated, oil-bathed, multi-plate clutch sits up high, indicating a stacked gearbox, and the bevel gears for the shaft final drive slide out along with the transmission, cassette-style, as on a MotoGP racer. Past BMWs have had their driveshafts on the right, but with the new engine it was necessary to move the shaft to the left to retain a left-side shifter, and to allow the huge muffler to tuck in tight against the rear wheel on the right for maximum cornering clearance.

The sparse specifications sheet I was shown listed a bore of 79mm and a stroke of 59mm for a displacement of 1156cc. Claimed output is currently 157 horsepower and 91 foot-pounds of torque, though with testing ongoing, those numbers are likely to go up. Top speed is said only to be “greater than 200 kilometers per hour,” but realistically, it’s closer to 300 kph (186 mph), the universally agreed-upon maximum adopted by the major motorcycle manufacturers. Even with the bike weighing in at a relatively heavy “less than 255 kilos” (561 pounds, nearly identical to a Hayabusa) with a full fuel tank, performance should be impressive.

Harnessing that power is an aluminum chassis that is anything but conventional, even if at first glance that doesn’t appear to be the case. It’s only when you look closer that you notice the cast “wheel carrier” for the Duolever fork and the horizontal frame spars that join the pivot points for the lower A-arm up front and the conventional swingarm in the rear. An inverted U-shaped structure supports the fork’s upper A-arm, the top shock mount, the handlebars and the scissors link that transmits steering inputs to the fork. All welds are flawless, BMW having perfected the art of aluminum welding on the R 1200C’s Telelever arm, which became a work of art after it was polished to a fine sheen. Never mind that the prototype K12 frames I saw were welded by humans-the robots should do an even better job once they’re programmed. I met the technician who was performing this intensive task, and he expected it to take him a week! Each of the frame’s 10 pieces (compared to 86 on the new GS’s steel frame) is machined where it connects with another for the best possible fit.

When the chassis engineers first showed me a slide of the Duolever fork, I applauded them, remarking that I’d long felt the previous-generation Telelever was a sort of “half-step” toward this Hossack-style setup. Wrong thing to say: They quickly informed me that Telelever was indeed the best solution for previous applications, particularly the GS, because Duolever couldn’t be made to work with much more than the K12’s 4.1 inches of wheel travel.

While the advantages of Duolever are mainly the same as with Telelever-namely the separation of steering and suspension functions-Duolever offers the additional benefit of letting engineers precisely prescribe the arc of the front wheel’s movement. They also were able to fine-tune how far the front end dives under braking, to give riders some semblance of the feel of a traditional telescopic fork without adversely affecting suspension compliance. Even more so than Telelever, the new Duolever setup with its roller bearings and ball joints exhibits none of the stiction inherent in telescopic forks, which try to bend under braking, thus it is free to absorb even small pavement imperfections when the brakes are applied.

Isolated from these suspension forces, the K1200S’s steering head could be made quite light, because it only needs to support the weight of the rider under braking and during steering inputs. Or so it would seem: It actually needs to be stronger than that for the simple reason that a bike is sometimes strapped down by its handlebar or picked up by a bar end after being dropped. Better to design in those considerations than to realize them later out in the field-perhaps literally!

Considering the K1200S’s groundbreaking front suspension, it would be easy to overlook the rear, but that, too, is allnew. Not just because the Paralever torque arm is now on top of the single-sided swingarm instead of on bottom-that’s merely a familial styling cue from the new R1200GS, which had its torque arm moved up out of harm’s way for off-road use. Similarly, the large-diameter hollow rear axle is largely a styling note, meant to accentuate the bike’s lightness, though it does offer some benefit in reducing heat in the wheel bearings at high speeds. No, the real news is that this is the first full-sized BMW with a rising-rate linkage, that feature only having been employed on F650 Singles before. While most of the engineers I spoke with diverted questions about reference models, one did concede that they strived to match the performance of the MV Agusta F4’s rear suspension.

Calculating the stresses the frame would be subjected to let the engineers specify the shape and thickness of the various castings and extrusions for optimum rigidity.

Computer simulations then let them work out weave, wobble and kickback issues, so that when they built the first prototype, it already worked. The test rider only had to adjust the suspension.

Dr. Braunsperger confirmed this best-case scenario, saying, “Our first prototype had a quite good setup that has been further improved by riding. R&D testing is very important, not just for reliability but for seat-of-the-pants feel. It’s very important that we don’t get a ‘computer bike.’”

One other facet in which the K1200S’s chassis promises to one-up the competition is suspension adjustability. While the base model will likely be sold with conventional manual adjustments, an option will be electronically adjustable suspension wherein the rider can choose from predetermined settings via a handlebar-mounted switch. No more crawling around on hands and knees! Gone is the thick, heavy wiring harness, as well as the fusebox-electronic transistors now diagnose defects and store the info in the central error memory. A standard anti-theft system uses a transponder in the ignition key that communicates with one of the ECUs, changing its i.d. number via a “challenge response algorithm.” Two keys come with the bike, and don’t lose them-they’re expensive to replace.

Predictably, the K12 is equipped with a car-like CAN BUS electrical system wherein no fewer than five ECUs communicate with one another digitally over just two wires.

But enough details. The first complete “bike” I saw was actually a full-sized mockup painted canary yellow, which I told David Robb, VP of Design, reminded me of the original K1200RS-probably not what he was hoping to hear from the first person outside the company to view it!

Or then again, maybe it was: “On paper, the idea of a transverse-Four seemed familiar,” he said, “but people were concerned that it wouldn’t look like a BMW. Iconic references took on added importance.”

Robb showed me a Powerpoint presentation that included silhouettes of three rival brands: “XX, Y and Z.” (No points for guessing which is which!) The fairings of all three had what he called “snowplow” cowlings, which draw the viewer’s eye to the ground. Furthermore, he noted that these bikes’ twin-spar aluminum frames cut them in half, making them look heavy in front and light in back.

With the K12, Robb’s team-led by 17-year veteran Edgar Heinrich-strived to use the horizontal frame spars to advantage. They chose to separate the aerodynamic bodywork on top from the technical parts below, even going so far as to paint the fairing lowers black. Thus the eye is drawn up and away to the airy, delta-style F-16 tail wings. Airfoils on the fairing sides add a touch of automotive class, as does the familiar blue-and-white BMW roundel on each side, awarded a place of honor “as though it’s being presented,” remarked Robb.

Throughout the project, the designers and engineers worked hand-in-hand to develop parts that not only looked good, but worked well. That teamwork resulted in the light, dynamic wheels, made by Brembo to BMW’s design, wherein material was placed only where it was needed to deal with the various stresses (and the valve stems were placed in the base of a spoke, where you can reach them with an air hose). The two teams going to the wind tunnel together resulted in the V-shaped notches on the fairing sides that channel rain water down and away from the rider, as well as the NACA duct in the front fender that routes cooling air up to the corners of the one-piece radiator.

As with most recent sportbikes, much emphasis was placed on integrating components, and making single parts perform multiple tasks. Two such examples on the K12 are the plastic headlight supports: Because the scissors link takes up the space in front of the steering head, the headlight had to be supported from the sides, and its brackets pull double (sextuple?) duty as mounts for the upper fairing, mirrors, instruments, air-intake ducts, various cables and one ECU.

One crucial “component” that obviously needed to be integrated was the rider, and no fewer than 20 test riders from outside the R&D department rode prototypes to ensure that the bike fit humans of all shapes and sizes. Because there’s more to seat height than how many inches it is above terra firma, engineers measured the distance from the ground up and over the seat and back down to the ground on the other side, and compared that to other models. So while the K12’s 32.3-inch-high seat sounds tall, it’s effectively lower than that because it’s so slim at the front.

Sure enough, throwing a leg over the bike confirmed that the seating position is quite roomy and comfortable, with lowish, moderately rearset footpegs, a narrow gas tank and a considerable lean forward to the handlebars that will likely feel more natural at speed. The rider isn’t locked in place, like he was on the K1200RS, and the fairing would appear to be quite protective, with the windscreen flaring at its outer edges to divert air up and over the rider’s shoulders. It seems like the sort of place one could spend a long, trouble-free day at speed, which is exactly what its builders had in mind.

With the formal press introduction slated for late July, no one outside BMW has yet had a chance to ride the K1200S, so until then all we have to go on are Dr. Braunsperger’s comments. An enthusiastic, experienced rider who competed in the final round of the 2003 BMW BoxerCup Championship, he looked me in the eye and said, “You’re going to like it! With Duolever, sensitivity is greatly enhanced, and braking will probably set a new benchmark. The challenge today is not to make bikes more powerful, but to make them more rideable. We think the K1200S will make every rider a better rider.”

Amen to that.