To “Be” or not to “Be”

TDC

Kevin Cameron

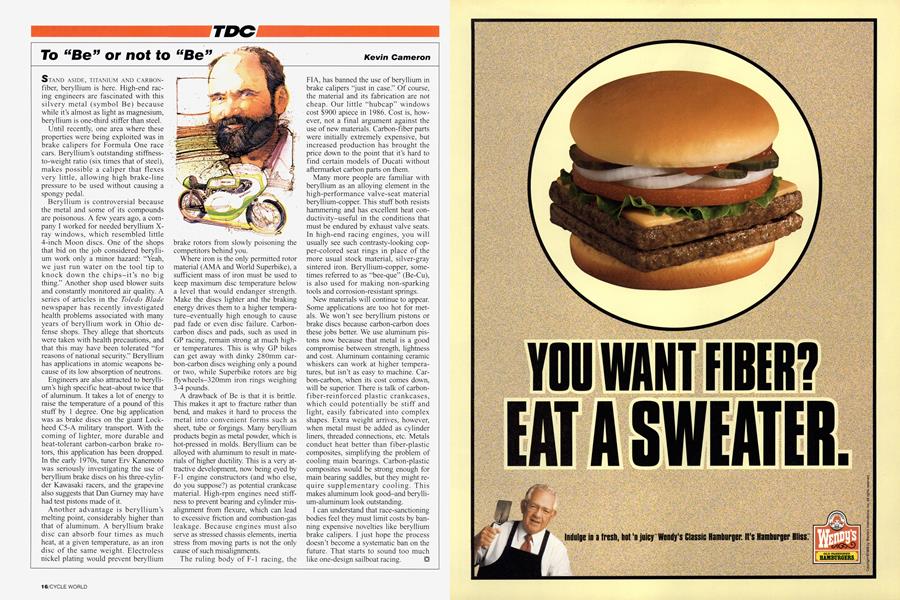

STAND ASIDE, TITANIUM AND CARBONfiber, beryllium is here. High-end racing engineers are fascinated with this silvery metal (symbol Be) because while it’s almost as light as magnesium, beryllium is one-third stiffer than steel.

Until recently, one area where these properties were being exploited was in brake calipers for Formula One race cars. Beryllium’s outstanding stiffnessto-weight ratio (six times that of steel), makes possible a caliper that flexes very little, allowing high brake-line pressure to be used without causing a spongy pedal.

Beryllium is controversial because the metal and some of its compounds are poisonous. A few years ago, a company I worked for needed beryllium Xray windows, which resembled little 4-inch Moon discs. One of the shops that bid on the job considered beryllium work only a minor hazard: “Yeah, we just run water on the tool tip to knock down the chips-it’s no big thing.” Another shop used blower suits and constantly monitored air quality. A series of articles in the Toledo Blade newspaper has recently investigated health problems associated with many years of beryllium work in Ohio defense shops. They allege that shortcuts were taken with health precautions, and that this may have been tolerated “for reasons of national security.” Beryllium has applications in atomic weapons because of its low absorption of neutrons.

Engineers are also attracted to beryllium’s high specific heat-about twice that of aluminum. It takes a lot of energy to raise the temperature of a pound of this stuff by 1 degree. One big application was as brake discs on the giant Lockheed C5-A military transport. With the coming of lighter, more durable and heat-tolerant carbon-carbon brake rotors, this application has been dropped. In the early 1970s, tuner Erv Kanemoto was seriously investigating the use of beryllium brake discs on his three-cylinder Kawasaki racers, and the grapevine also suggests that Dan Gurney may have had test pistons made of it.

Another advantage is beryllium’s melting point, considerably higher than that of aluminum. A beryllium brake disc can absorb four times as much heat, at a given temperature, as an iron disc of the same weight. Electroless nickel plating would prevent beryllium brake rotors from slowly poisoning the competitors behind you.

Where iron is the only permitted rotor material (AMA and World Superbike), a sufficient mass of iron must be used to keep maximum disc temperature below a level that would endanger strength. Make the discs lighter and the braking energy drives them to a higher temperature-eventual ly high enough to cause pad fade or even disc failure. Carboncarbon discs and pads, such as used in GP racing, remain strong at much higher temperatures. This is why GP bikes can get away with dinky 280mm carbon-carbon discs weighing only a pound or two, while Superbike rotors are big flywheels-320mm iron rings weighing 3-4 pounds.

A drawback of Be is that it is brittle. This makes it apt to fracture rather than bend, and makes it hard to process the metal into convenient forms such as sheet, tube or forgings. Many beryllium products begin as metal powder, which is hot-pressed in molds. Beryllium can be alloyed with aluminum to result in materials of higher ductility. This is a very attractive development, now being eyed by F-l engine constructors (and who else, do you suppose?) as potential crankcase material. High-rpm engines need stiffness to prevent bearing and cylinder misalignment from flexure, which can lead to excessive friction and combustion-gas leakage. Because engines must also serve as stressed chassis elements, inertia stress from moving parts is not the only cause of such misalignments.

The ruling body of F-l racing, the FIA, has banned the use of beryllium in brake calipers “just in case.” Of course, the material and its fabrication are not cheap. Our little “hubcap” windows cost $900 apiece in 1986. Cost is, however, not a final argument against the use of new materials. Carbon-fiber parts were initially extremely expensive, but increased production has brought the price down to the point that it’s hard to find certain models of Ducati without aftermarket carbon parts on them.

Many more people are familiar with beryllium as an alloying element in the high-performance valve-seat material beryllium-copper. This stuff both resists hammering and has excellent heat conductivity-useful in the conditions that must be endured by exhaust valve seats. In high-end racing engines, you will usually see such contrasty-looking copper-colored seat rings in place of the more usual stock material, silver-gray sintered iron. Beryllium-copper, sometimes referred to as “bee-que” (Be-Cu), is also used for making non-sparking tools and corrosion-resistant springs.

New materials will continue to appear. Some applications are too hot for metals. We won’t see beryllium pistons or brake discs because carbon-carbon does these jobs better. We use aluminum pistons now because that metal is a good compromise between strength, lightness and cost. Aluminum containing ceramic whiskers can work at higher temperatures, but isn’t as easy to machine. Carbon-carbon, when its cost comes down, will be superior. There is talk of carbonfiber-reinforced plastic crankcases, which could potentially be stiff and light, easily fabricated into complex shapes. Extra weight arrives, however, when metal must be added as cylinder liners, threaded connections, etc. Metals conduct heat better than fiber-plastic composites, simplifying the problem of cooling main bearings. Carbon-plastic composites would be strong enough for main bearing saddles, but they might require supplementary cooling. This makes aluminum look good-and beryllium-aluminum look outstanding.

I can understand that race-sanctioning bodies feel they must limit costs by banning expensive novelties like beryllium brake calipers. I just hope the process doesn’t become a systematic ban on the future. That starts to sound too much like one-design sailboat racing.

View Full Issue

View Full Issue