Mixing it

TDC

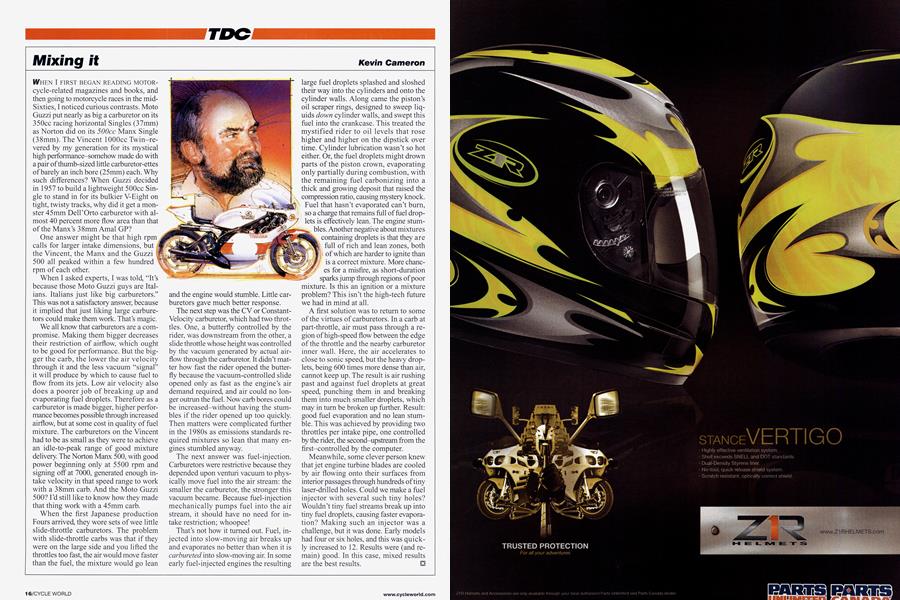

WHEN I FIRST BEGAN READING MOTORcycle-related magazines and books, and then going to motorcycle races in the mid-Sixties, I noticed curious contrasts. Moto Guzzi put nearly as big a carburetor on its 350cc racing horizontal Singles (37mm) as Norton did on its 500cc Manx Single (38mm). The Vincent lOOOcc Twin-revered by my generation for its mystical high performance-somehow made do with a pair of thumb-sized little carburetor-ettes of barely an inch bore (25mm) each. Why such differences? When Guzzi decided in 1957 to build a lightweight 500cc Single to stand in for its bulkier V-Eight on tight, twisty tracks, why did it get a monster 45mm Dell’Orto carburetor with almost 40 percent more flow area than that of the Manx’s 38mm Amal GP?

One answer might be that high rpm calls for larger intake dimensions, but J the Vincent, the Manx and the Guzzi 500 all peaked within a few hundred rpm of each other.

When I asked experts, I was told, “It’s because those Moto Guzzi guys are Italians. Italians just like big carburetors.” This was not a satisfactory answer, because it implied that just liking large carburetors could make them work. That’s magic.

We all know that carburetors are a compromise. Making them bigger decreases their restriction of airflow, which ought to be good for performance. But the bigger the carb, the lower the air velocity through it and the less vacuum “signal” it will produce by which to cause fuel to flow from its jets. Low air velocity also does a poorer job of breaking up and evaporating fuel droplets. Therefore as a carburetor is made bigger, higher performance becomes possible through increased airflow, but at some cost in quality of fuel mixture. The carburetors on the Vincent had to be as small as they were to achieve an idle-to-peak range of good mixture delivery. The Norton Manx 500, with good power beginning only at 5500 rpm and signing off at 7000, generated enough intake velocity in that speed range to work with a 38mm carb. And the Moto Guzzi 500? I’d still like to know how they made that thing work with a 45mm carb.

When the first Japanese production Fours arrived, they wore sets of wee little slide-throttle carburetors. The problem with slide-throttle carbs was that if they were on the large side and you lifted the throttles too fast, the air would move faster than the fuel, the mixture would go lean

and the engine would stumble. Little carburetors gave much better response.

The next step was the CV or ConstantVelocity carburetor, which had two throttles. One, a butterfly controlled by the rider, was downstream from the other, a slide throttle whose height was controlled by the vacuum generated by actual airflow through the carburetor. It didn’t matter how fast the rider opened the butterfly because the vacuum-controlled slide opened only as fast as the engine’s air demand required, and air could no longer outrun the fuel. Now carb bores could be increased-without having the stumbles if the rider opened up too quickly. Then matters were complicated further in the 1980s as emissions standards required mixtures so lean that many engines stumbled anyway.

The next answer was fuel-injection. Carburetors were restrictive because they depended upon venturi vacuum to physically move fuel into the air stream: the smaller the carburetor, the stronger this vacuum became. Because fuel-injection mechanically pumps fuel into the air stream, it should have no need for intake restriction; whoopee!

That’s not how it turned out. Fuel, injected into slow-moving air breaks up and evaporates no better than when it is carbureted into slow-moving air. In some early fuel-injected engines the resulting

large fuel droplets splashed and sloshed their way into the cylinders and onto the cylinder walls. Along came the piston’s oil scraper rings, designed to sweep liquids down cylinder walls, and swept this fuel into the crankcase. This treated the mystified rider to oil levels that rose higher and higher on the dipstick over time. Cylinder lubrication wasn’t so hot either. Or, the fuel droplets might drown parts of the piston crown, evaporating only partially during combustion, with the remaining fuel carbonizing into a thick and growing deposit that raised the compression ratio, causing mystery knock. Fuel that hasn’t evaporated can’t burn, so a charge that remains full of fuel droplets is effectively lean. The engine stumbles. Another negative about mixtures containing droplets is that they are full of rich and lean zones, both of which are harder to ignite than is a correct mixture. More chances for a misfire, as short-duration sparks jump through regions of poor mixture. Is this an ignition or a mixture problem? This isn’t the high-tech future we had in mind at all.

A first solution was to return to some of the virtues of carburetors. In a carb at part-throttle, air must pass through a region of high-speed flow between the edge of the throttle and the nearby carburetor inner wall. Here, the air accelerates to close to sonic speed, but the heavy droplets, being 600 times more dense than air, cannot keep up. The result is air rushing past and against fuel droplets at great speed, punching them in and breaking them into much smaller droplets, which may in turn be broken up further. Result: good fuel evaporation and no lean stumble. This was achieved by providing two throttles per intake pipe, one controlled by the rider, the second-upstream from the first-controlled by the computer.

Meanwhile, some clever person knew that jet engine turbine blades are cooled by air flowing onto their surfaces from interior passages through hundreds of tiny laser-drilled holes. Could we make a fuel injector with several such tiny holes? Wouldn’t tiny fuel streams break up into tiny fuel droplets, causing faster evaporation? Making such an injector was a challenge, but it was done. Early models had four or six holes, and this was quickly increased to 12. Results were (and remain) good. In this case, mixed results are the best results. □

Kevin Cameron

View Full Issue

View Full Issue