Trouble with turbines

TDC

Kevin Cameron

COMPARING THE FOUR-CYCLE RECIPROCating internal-combustion engine with other prime movers reveals where its weaknesses and compromises are, and how much we are paying for them.

In a gas-turbine engine, for instance, each function-compression, combustion and expansion (power)-occurs in a different part of the engine, specialized for only that function. In a piston engine, all these functions occur in the same cylinder. Let's see what this implies.

In the turbine, air enters a compressor and is compressed. The compressor takes the form either of a centrifugal or axial dynamic machine; that is, air is compressed by being flung about-ac celerated-by impellers moving at or above the speed of sound. This enables the compressor to be very light for the volume of air it handles. In the piston engine, compression is, unfortunately, performed by using the same piston and cylinder that will later be used for com bustion, expansion and exhaust. This is a waste because the peak pressure of compression is much less than the peak pressure of combustion-yet the same machinery, dimensioned for the higher pressure, is used for both. Instead of dy namic compression, the piston engine compresses its air by making the con tainer (the cylinder) smaller. This, in turn, requires near-perfect sealing.

In the turbine, the compressed air flows to one or more burners, where fuel is sprayed into it and continuously burned. In the piston engine, combustion results in a 4or 5-to-i pressure rise, but this is impractical in a turbine because any such pressure rise would blow back through the compressor and stall the en gine. The piston engine makes power from a rise in gas pressure from combus tion, but the turbine relies on a combus tion-generated increase in gas volume for its power. Pressure pushes pistons, but flow volume drives turbines.

Another important difference arises here. In the piston engine, combustion is intermittent, occupying only about 10 percent of the whole 720-crankshaftdegree engine cycle. This allows the "burner" (the combustion chamber, pis ton crown and exposed valve parts) to survive the extremely high temperature caused by reacting all the air in the cylinder with fuel. In the gas turbine, only about 25 percent of the total en gine airflow can actually be burned with fuel. The rest is used to create in sulating layers of airflow to protect the thin sheet-metal parts of the burner cans. Turbine designers would love to burn all the air that their engines com press, but even the most exotic burner and turbine metals cannot tolerate it. The piston engine tolerates it because the heating is intermittent.

The penalty that the piston engine pays for its ability to contain and seal high pressures is great weight and friction for the power it makes. Where the highest pressure in a gas turbine might be 300 psi, peak combustion pressure in a mo torcycle engine is over 1000 psi. It takes real beef to contain this pressure-and to transmit it through thrashing metal rods and pressure-oiled bearings to a whirling crankshaft. The turbine spins at a contin uous high speed, and the largest forces in it are steady centrifugal loads, tending to stretch turbine and compressor blades. In the piston engine, peak loads from the accelerations and decelerations of its pistons often exceed the loads from combustion-gas pressure. This is espe cially so when displacement limits force designers to seek power from high rpm. In energy terms, it's much better for pis ton engines to make power at the lowest possible rpm because this minimizes bearing and sealing friction. Low rpm and high pressure are keys to mechanical efficiency in piston engines.

Sealing is another issue. The turbine seals by making clearances between moving blades and their casings ex tremely small-but there is leakage that may make automotive-sized turbines impractical. In bigger engines, leakage flows become a smaller proportion of total airflow. But in a piston engine, sealing has to be a fetish because of the high pressure. This allows efficient en gines to be built in almost any size. To allow a piston to move in a cylinder full of 1000-psi gas requires a sliding seal (rings) that inevitably generates a lot of friction. This and the fact that crank and rod bearings must support the same pressure adds up to a hefty bill for friction-maybe 15 percent of power output at highway speeds, and more like 25 percent at racy high rpm. By contrast, friction in gas turbines is practically nothing, a small fraction of one percent of total power output.

The piston engine has one giant sav ing grace: It can be throttled and remain efficient over a wide load range. You adjust power by simply opening or clos ing the throttle. The turbine's compres sor is efficient only near the top of its rpm range, and because the machine is in effect a huge turbocharger, it has throttle lag like nothing else. The piston engine's loss-producing pressure-seal ing system allows it to compress air over a wide range of rpm, and to change load almost instantly. It can idle at 5-10 percent of its peak rpm, then accelerate to (just for example) 176 mph on Cycle World's secret test highway. The tur bine's compressor has to be near peak rpm at all times to achieve efficiency, but the piston engine's efficiency is built into its compression ratio.

It's too bad that the piston engine has to use its heavy power piston to com press air and pump out exhaust. That means machinery designed for 1000 psi wastes much of its time handling 200 psi (compression) airflow and 100 psi (exhaust) airflow. But in return for this misuse of resources, we get a rea sonably efficient machine that can be throttled enough to maneuver in and out of garages, and creep through city traffic at less than a zillion rpm. Power per pound looks pretty feeble com pared with turbines (that's why only little putt-putt airplanes still have pis ton engines), but in return for these drawbacks we do get a prime mover well-suited to operation down here on the earth's surface, where conditions change rapidly and there are obstacles like corners, policemen and thousands of competing vehicles.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontGood News And Bad

September 1998 By David Edwards -

Leanings

LeaningsPassing Temptations

September 1998 By Peter Egan -

Letters

LettersLetters

September 1998 -

Roundup

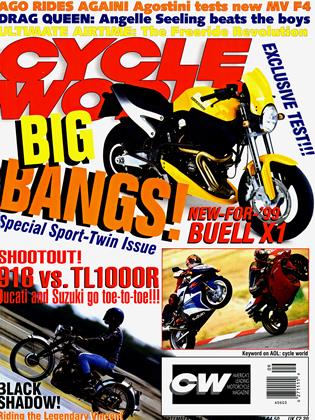

RoundupBig-Bore Hornet Set To String

September 1998 By Matthew Miles -

Roundup

RoundupNew For '99: Dirt

September 1998 By Jimmy Lewis -

Roundup

RoundupEtc.

September 1998