EFI at Last!

Software triumphs over hardware as we enter the age of fuel injection

KEVIN CAMERON

HAS THE GREAT DAY COME? FOR YEARS, I HAVE believed that quantity production of motorcycle fuel injection could drive its price below that of conventional carburetors. Carburetors are complex castings carefully machined, then covered with linkages and other gadgetry—different for every model. Fuel injection is a modular system consisting of a fuel pump, throttle bodies, injectors and a computer to control them. The same fuel pump and computer can be used on many models, with only throttle-body size being different.

Who cares? All concerned motorcyclists. The future draws upon us, bringing with it tighter emissions regulations. Fuel injection is the most potent single tool in future compliance strategies, whereas carburetors have been holding back four-stroke performance for years, as follows:

As the piston comes to TDC after the exhaust stroke, the exhaust valves are closing while the intakes are beginning to open. This period when both are slightly open together is called, appropriately, overlap. For performance in the powerband, overlap should be large, because this allows a properly timed negative wave from the exhaust pipe to suck exhaust residue from the cylinder, then travel through to the intake to start the fresh charge flowing-all before the piston has even moved into its intake stroke. This boosts torque, which is dandy. What's not so dandy is that as fresh mixture is drawn through the cylinder in this way, some goes out the exhaust pipe to become illegal emissions.

Something worse happens when the engine runs at 70 to 75 percent of peak-power revs. With the engine turning slower, but the pipe waves still moving at the speed of sound, the negative pipe wave hits early, before overlap. It is a following, positive wave that hits overlap instead. Its pressure pushes exhaust back into the cylinder, through the intake and carburetor. As this inert, useless gas blows back, it picks up fuel from the carburetor, which is too dull-witted to care which way gas flows through it, or even what that gas may be. When the piston begins its intake stroke, that fuel-rich exhaust gas is drawn back in through the carb a second time, getting carbureted twice to become double-rich. Finally, fresh air is drawn in to finish filling the cylinder. Badly over-rich now, the cylinder misfires or, at best, burns slowly and late, giving little power and a generous flow of unbumed hydrocarbons. This is the celebrated rich flat spot in the torque curve.

Either way, the emissions agencies won't have it, so motorcycle makers have responded by minimizing valve overlap-useful though it would be in boosting peak power. No overlap, no drippy flow of unburned hydrocarbons, no emissions hassle.

Now, with trumpet fanfare and dancing girls, enter fuel injection. Fuel injection is intelligent, so on a long-overlap engine like the Ducati 916, it does not add fuel to exhaust gas blowback as carburetors do. Instead, it wisely waits until the intake stroke actually begins, and then adds only enough fuel to mix correctly with the fresh air that the engine actually gets. No double-richness, no weak combustion or misfire, no fuel short-circuited to the exhaust pipe-just nice, smooth running with minimum emissions. In this way, fuel injection allows the engine designer to use as much valve overlap as he'd like, without punishing him with emissions problems or a severe flat spot in the powerband.

It must be starting to catch on. Three of the engines in our four-bike comparison have fuel injection, and all three systems are remarkably similar in how they work.

Early automotive fuel-injection systems directly measured the airflow into the engine with an air meter, and proportioned fuel accordingly. More recent ones correct this information by use of an oxygen sensor in the exhaust, and a feedback control loop. This is called "closed loop" control.

The bike systems we are considering work differently, and are called "mapped" or "open-loop" systems. The engine's air-taking ability is measured once at the factory on a dyno, under all combinations of throttle opening and rpm. This data is then stored in a look-up table, on a ROM chip in every fuel-injection computer produced. As an engine runs, sensors report engine rpm and throttle position to the computer, which then looks up the corresponding injector on-time for those conditions. Finally, it sends a pulse of the correct length to the injector, which holds its spray valve open only long enough to inject the correct amount of fuel for that intake stroke. The look-up table data is called a map because, presented in graphic form, it defines a complex curved surface very like a topographic survey map of hills and valleys. Latitude and longitude are "n" and "alpha," while altitude is proportional to injector on-time. This stored data takes the place of an air meter on each engine. Changes in atmospheric conditions, engine temperature, airbox pressure, etc. are reported to the computer by a variety of sensors in each of these systems. Rotational position of the engine is reported by sensors on the crank and one camshaft.

Open-loop EFI is appropriate for motorcycles now because it combines useful capability to reduce emissions, can sharpen up throttle response and civilize the warm-up process, and still deliver excellent performance. With carburetors, by contrast, it was necessary to resort to less desirable cam profiles and to tip-toe perilously along the edge of leanness to meet emissions standards. The greater accuracy and intelligence of EFI make it possible to have low emissions without falling off the edge into leanness.

If motorcycle emissions standards are further tightened, closed-loop control with oxygen sensors and an exhaust catalyst is a next step. BMW has already gone this way voluntarily.

The Ducati's Weber-Marelli system is Formula Onederived, using a computer developed for production cars. That of the Triumph T595 is a French-developed Sagem system, also F-l related, while Suzuki's system is proprietary.

While the Weber and Sagem systems are "n-alpha" (n=rpm, alpha=throttle angle) all the time, Suzuki's system switches at low throttle/rpm to a speed-density system. These systems are quite sophisticated. The Weber, for example, is operated with separate, slightly different information for the special requirements of each of the two cylinders. The Sagem system includes an idle-speed control; where an automotive system would use a motorized throttle positioner, the Sagem drives a small airbleed valve to accomplish the same thing. As I am fond of saying, once you have the computer on the motorcycle, there's no problem finding more work for it!

Over past seasons, we have all heard the concerns of Ducati race teams to have the "hot" chip, encoding the latest performance developments. This system is also computer-addressable, either on the dyno or in the field, so that fresh data can be entered. Triumph uses a small hand-held unit called a "Datatool," through which system parameters in the Sagem MC2000 computer may be adjusted by users. It's expected that this device will sell for as little as a few hundred dollars to dealers, and perhaps to some technically driven owners as well. Devices like this Datatool are the electronic equivalent of jet kits for carburetors, substituting software for hardware. So far, no information is available about means of addressing the Suzuki system, but you can be sure we'll be hearing about it soon.

In all three cases, these are true engine-management systems, integrating ignition timing with fuel delivery to control overall performance.

First-generation EFI systems were limited by their computers' processing speeds. The slower the computer, the less often it can scan changing data, then recompute ignition timing and fuel delivery. In some cases, as rpm rose, such limited systems simply disregarded some data, or recalculated less often. The result of slow computation is a poorer match to the engine's true requirements, with the computer's solution resembling follow-the-dots rather than the smooth curve of the engine's real needs. Triumph notes that its 16-bit Sagem system operates at a 3 MHz clock speed-adequate for full-function operation up to 18,000 rpm, even though redline for the T595 is 10,500 rpm.

As industry demand for engine-management computer chips has risen, costs have fallen and computation speed and sophistication have risen. All this is routine business in the automotive world, but it is new to motorcycling.

Welcome to the club.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Oakland Rodders

April 1997 By David Edwards -

Leanings

LeaningsCheesy Circumstances

April 1997 By Peter Egan -

TDC

TDCDevelopment Power

April 1997 By Kevin Cameron -

Letters

LettersLetters

April 1997 -

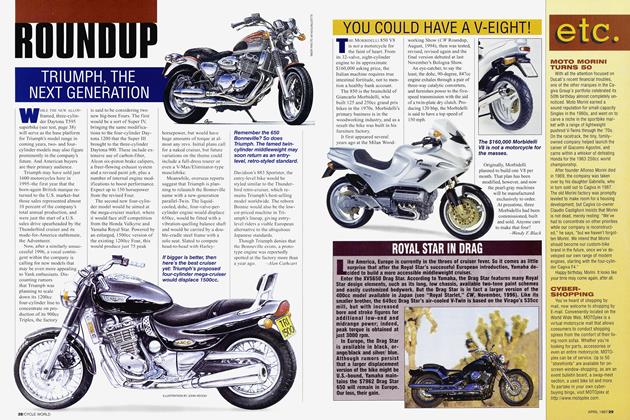

Roundup

RoundupTriumph, the Next Generation

April 1997 By Alan Cathcart -

Roundup

RoundupYou Could Have A V-Eight!

April 1997 By Wendy F. Black