Cathedrals and TZ75Os

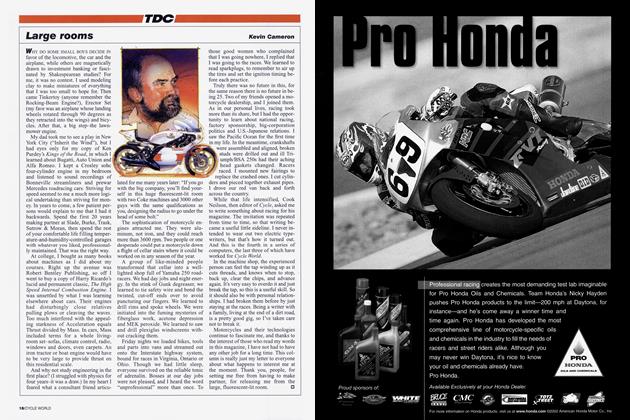

TDC

MOST OF MY TRIPS TO EUROPE HAVE BEEN to motor-racing circuits, but there are good reasons to make side trips to the great Gothic cathedrals. Like the fuse lages of aircraft and the chassis beams of sportbikes, these are thin shells. While familiar vehicle structures are internally stiffened by bulkheads or ribs, the cathedrals went about it differently. Made of stone, they are held together almost entirely by gravity and good fit, with a little help from low-tensile strength mortar. The major stress to be dealt with is lateral thrust from the vaulted stone ceiling, which tends to wedge the walls apart. These forces were countered by what are really external bulkheads-the flying buttresses.

Anyone who has built model air planes of the sticks-and-paper variety is familiar with internal bulkheads, or formers. An aircraft fuselage is really a large, thin-walled tube. In a metal aircraft, its strength comes from its thin sheet covering, prevented from buckling locally by regularly spaced bulkheads and ribs within.

Effectively the same are the twinbeam chassis of modern sportbikes. As the metal thickness is reduced in the in terest of light weight, buckling becomes the failure mode. This is prevented by providing internal stiffening-sometimes as separate pieces, welded in place, sometimes as extruded dividers. In the case of flying buttresses, the vault forces tending to push out the walls were reacted to the ground. In the case of beam structures like aircraft fuse lages, buckling forces are reacted inter nally, to other parts of the structure.

Just as bike builders want to use the lightest possible chassis, so the cathe dral builders needed to reduce the vol ume of accurately cut stonework in their structures to something the host city could afford. That means, in both cases, reduced material thicknesses. And that, in turn, brings the chance of buckling and failure, and the need for bracing.

Wind exerts enormous forces on large buildings, and this was added to the static forces the cathedral builders had to handle. The great cathedrals like Chartres were built longitudinally, from buttress to buttress, one section at a time. During the years of con struction, high winds were sure to occur. Such wind provided the "stress laboratory" that allowed the engineer to check his work. Because Medieval mortar had a low tensile strength, it was the weak link in the job. After a windstorm, the chief engineer would climb the scaffolding to closely exam ine the mortar in the already complet ed sections of the church, checking for cracks that would indicate excessive local tensile stress. This either gave him the confidence to go ahead with the existing plan, or gave guidance as to where reinforcement was needed.

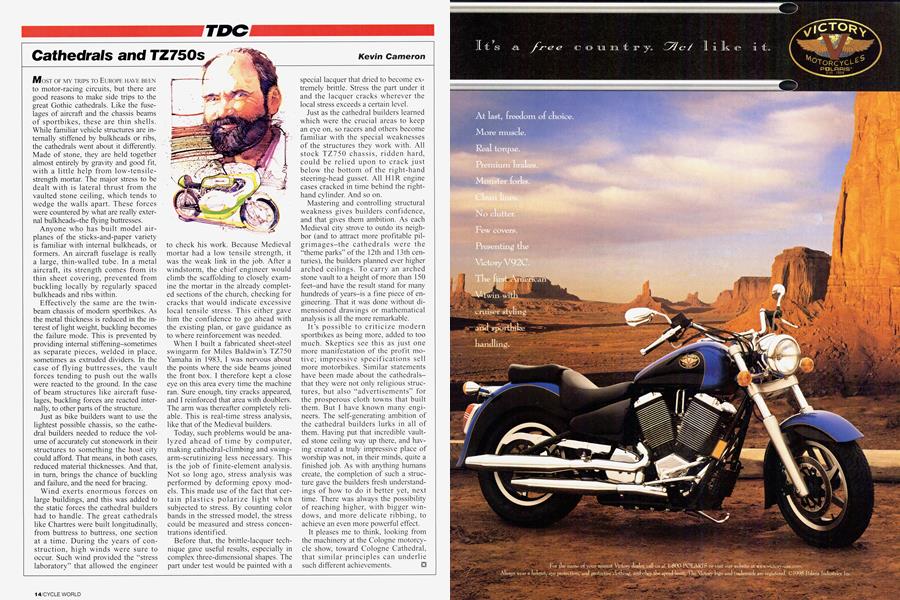

When I built a fabricated sheet-steel swingarm for Miles Baldwin's TZ750 Yamaha in 1983, I was nervous about the points where the side beams joined the front box. I therefore kept a close eye on this area every time the machine ran. Sure enough, tiny cracks appeared, and I reinforced that area with doublers. The arm was thereafter completely reli able. This is real-time stress analysis, like that of the Medieval builders.

Today, such problems would be ana lyzed ahead of time by computer, making cathedral-climbing and swingarm-scrutinizing less necessary. This is the job of finite-element analysis. Not so long ago, stress analysis was performed by deforming epoxy mod els. This made use of the fact that cer tain plastics polarize light when subjected to stress. By counting color bands in the stressed model, the stress could be measured and stress concen trations identified.

Before that, the brittle-lacquer tech nique gave useful results, especially in complex three-dimensional shapes. The part under test would be painted with a special lacquer that dried to become ex tremely brittle. Stress the part under it and the lacquer cracks wherever the local stress exceeds a certain level.

Just as the cathedral builders learned which were the crucial areas to keep an eye on, so racers and others become familiar with the special weaknesses of the structures they work with. All stock TZ750 chassis, ridden hard, could be relied upon to crack just below the bottom of the right-hand steering-head gusset. All H1R engine cases cracked in time behind the right hand cylinder. And so on.

Mastering and controlling structural weakness gives builders confidence, and that gives them ambition. As each Medieval city strove to outdo its neigh bor (and to attract more profitable pil grimages-the cathedrals were the "theme parks" of the 12th and 13th cen turies), the builders planned ever higher arched ceilings. To carry an arched stone vault to a height of more than 150 feet-and have the result stand for many hundreds of years-is a fine piece of en gineering. That it was done without di mensioned drawings or mathematical analysis is all the more remarkable.

It's possible to criticize modern sportbikes as being more, added to too much. Skeptics see this as just one more manifestation of the profit mo tive; impressive specifications sell more motorbikes. Similar statements have been made about the cathedralsthat they were not only religious struc tures, but also "advertisements" for the prosperous cloth towns that built them. But I have known many engi neers. The self-generating ambition of the cathedral builders lurks in all of them. Having put that incredible vault ed stone ceiling way up there, and hav ing created a truly impressive place of worship was not, in their minds, quite a finished job. As with anything humans create, the completion of such a struc ture gave the builders fresh understand ings of how to do it better yet, next time. There was always the possibility of reaching higher, with bigger win dows, and more delicate ribbing, to achieve an even more powerful effect.

It pleases me to think, looking from the machinery at the Cologne motorcy cle show, toward Cologne Cathedral, that similar principles can underlie such different achievements.

Kevin Cameron