Hot damn

TDC

Kevin Cameron

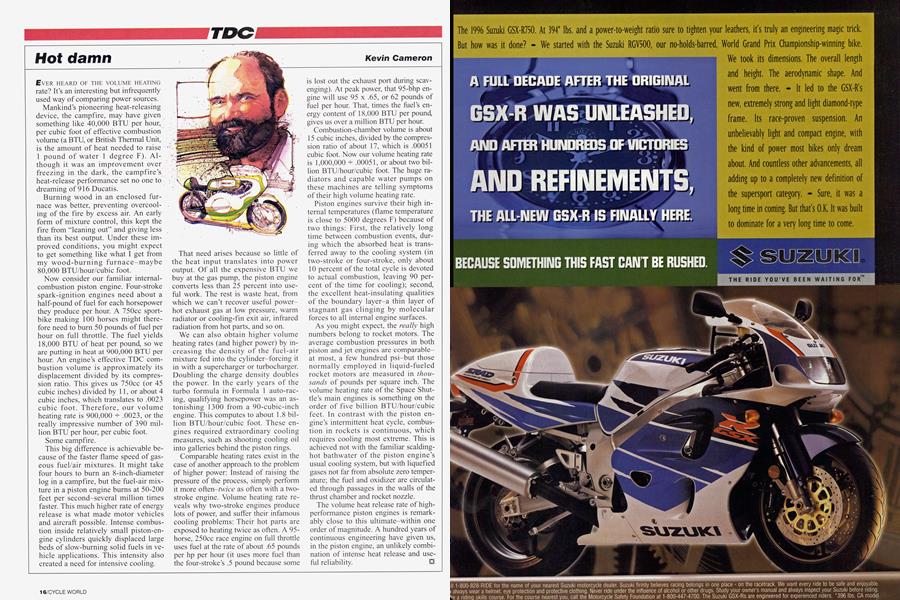

EVER HEARD OF THE VOLUME HEATING rate? It’s an interesting but infrequently used way of comparing power sources.

Mankind’s pioneering heat-releasing device, the campfire, may have given something like 40,000 BTU per hour, per cubic foot of effective combustion volume (a BTU, or British Thermal Unit, is the amount of heat needed to raise 1 pound of water 1 degree F). Although it was an improvement over freezing in the dark, the campfire's heat-release performance set no one to dreaming of 916 Ducatis.

Burning wood in an enclosed furnace was better, preventing overcooling of the fire by excess air. An early form of mixture control, this kept the fire from “leaning out” and giving less than its best output. Under these improved conditions, you might expect to get something like what I get from my wood-burning furnace-maybe

80.000 BTU/hour/cubic foot.

Now consider our familiar internalcombustion piston engine. Four-stroke spark-ignition engines need about a half-pound of fuel for each horsepower they produce per hour. A 750cc sportbike making 100 horses might therefore need to burn 50 pounds of fuel per hour on full throttle. The fuel yields

18.000 BTU of heat per pound, so we are putting in heat at 900,000 BTU per hour. An engine’s effective TDC combustion volume is approximately its displacement divided by its compression ratio. This gives us 750cc (or 45 cubic inches) divided by 11, or about 4 cubic inches, which translates to .0023 cubic foot. Therefore, our volume heating rate is 900,000 -E .0023, or the really impressive number of 390 million BTU per hour, per cubic foot.

Some campfire.

This big difference is achievable because of the faster flame speed of gaseous fuel/air mixtures. It might take four hours to burn an 8-inch-diameter log in a campfire, but the fuel-air mixture in a piston engine burns at 50-200 feet per second-several million times faster. This much higher rate of energy release is what made motor vehicles and aircraft possible. Intense combustion inside relatively small piston-engine cylinders quickly displaced large beds of slow-burning solid fuels in vehicle applications. This intensity also created a need for intensive cooling.

That need arises because so little of the heat input translates into power output. Of all the expensive BTU we buy at the gas pump, the piston engine converts less than 25 percent into useful work. The rest is waste heat, from which we can’t recover useful powerhot exhaust gas at low pressure, warm radiator or cooling-fin exit air, infrared radiation from hot parts, and so on.

We can also obtain higher volume heating rates (and higher power) by increasing the density of the fuel-air mixture fed into the cylinder-forcing it in with a supercharger or turbocharger. Doubling the charge density doubles the power. In the early years of the turbo formula in Formula 1 auto-racing, qualifying horsepower was an astonishing 1300 from a 90-cubic-inch engine. This computes to about 1.8 billion BTU/hour/cubic foot. These engines required extraordinary cooling measures, such as shooting cooling oil into galleries behind the piston rings.

Comparable heating rates exist in the case of another approach to the problem of higher power: Instead of raising the pressure of the process, simply perform it more often-tnuce as often with a twostroke engine. Volume heating rate reveals why two-stroke engines produce lots of power, and suffer their infamous cooling problems: Their hot parts are exposed to heating twice as often. A 95horse, 250cc race engine on full throttle uses fuel at the rate of about .65 pounds per hp per hour (it uses more fuel than the four-stroke’s .5 pound because some is lost out the exhaust port during scavenging). At peak power, that 95-bhp engine will use 95 x .65, or 62 pounds of fuel per hour. That, times the fuel’s energy content of 18,000 BTU per pound, gives us over a million BTU per hour.

Combustion-chamber volume is about 15 cubic inches, divided by the compression ratio of about 17, which is .00051 cubic foot. Now our volume heating rate is 1,000,000 -E .00051, or about two billion BTU/hour/cubic foot. The huge radiators and capable water pumps on these machines are telling symptoms of their high volume heating rate.

Piston engines survive their high internal temperatures (flame temperature is close to 5000 degrees F) because of two things: First, the relatively long time between combustion events, during which the absorbed heat is transferred away to the cooling system (in two-stroke or four-stroke, only about 10 percent of the total cycle is devoted to actual combustion, leaving 90 percent of the time for cooling); second, the excellent heat-insulating qualities of the boundary layer-a thin layer of stagnant gas clinging by molecular forces to all internal engine surfaces.

As you might expect, the really high numbers belong to rocket motors. The average combustion pressures in both piston and jet engines are comparableat most, a few hundred psi-but those normally employed in liquid-fueled rocket motors are measured in thousands of pounds per square inch. The volume heating rate of the Space Shuttle’s main engines is something on the order of five billion BTU/hour/cubic feet. In contrast with the piston engine’s intermittent heat cycle, combustion in rockets is continuous, which requires cooling most extreme. This is achieved not with the familiar scaldinghot bathwater of the piston engine’s usual cooling system, but with liquefied gases not far from absolute zero temperature; the fuel and oxidizer are circulated through passages in the walls of the thrust chamber and rocket nozzle.

The volume heat release rate of highperformance piston engines is remarkably close to this ultimate-within one order of magnitude. A hundred years of continuous engineering have given us, in the piston engine, an unlikely combination of intense heat release and useful reliability.

View Full Issue

View Full Issue