Cool stuff

TDC

Kevin Cameron

WHILE I WAS VISITING MY FOLKS REcently, I saw my father poke aluminum nails through potatoes before baking them in the oven. This, it seemed to me, wonderfully illustrated the state of coolant radiator design 80 years ago. The object of nailing the potatoes is to conduct heat into the centers of the spuds more rapidly, based on the idea that aluminum conducts heat faster than a mass of wet starch. This, it is asserted, causes the potatoes to cook faster.

The problem is this: About the same area of nail is exposed to the hot air in the oven as is buried in the potatoes. This is a poor arrangement because air is much less dense than the starch and water in the potato. The low-density air will be much less efficient at heat ing the exposed part of the nail than the high-density potato-stuff will be at cooling the buried part of it.

Now for the comparison to antique radiators: If you've ever been to an an tique car/motorcycle show or museum, you will have seen early-style "honey comb" coolant radiators. These are ef fectively just cereal-box-shaped metal containers, pierced through their thin dimension by hundreds of small, hexagonal metal tubes, each soldered in place. Cooling water fills the box and the complex space between the tubes, while outside air is encouraged to pass through the tubes to cool the water surrounding them.

The trouble is the same as with the potato nails-the area exposed to the low-density medium (the cooling air) is exactly the same as the area ex posed to the high-density medium (the cooling water). Depending on how you look at it, there is either too much area in contact with the high-density medium, or too little in contact with the low-density medium.

It's easy to see how to speed up potato baking; we'll just put wings or fins on the part of the nail exposed to the hot oven air. This exposes metal to a much larger amount of air, gathering heat that is then efficiently conducted into the potato. These "heating fins" are the conceptual reverse of the cool ing fins on an air-cooled engine's cylinder and head. The term for such things is, reasonably enough, `~sec ondary surface."

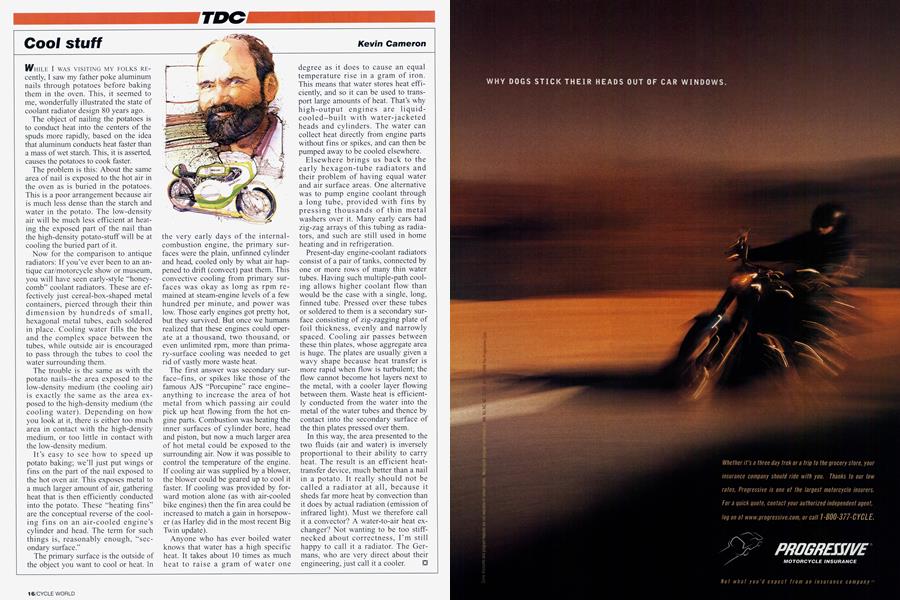

The primary surface is the outside of the object you want to cool or heat. In the very early days of the internalcombustion engine, the primary sur faces were the plain, unfinned cylinder and head, cooled only by what air hap pened to drift (convect) past them. This convective cooling from primary sur faces was okay as long as rpm re mained at steam-engine levels of a few hundred per minute, and power was low. Those early engines got pretty hot, but they survived. But once we humans realized that these engines could oper ate at a thousand, two thousand, or even unlimited rpm, more than prima ry-surface cooling was needed to get rid of vastly more waste heat.

The first answer was secondary sur face-fins, or spikes like those of the famous AJS "Porcupine" race engineanything to increase the area of hot metal from which passing air could pick up heat flowing from the hot en gine parts. Combustion was heating the inner surfaces of cylinder bore, head and piston, but now a much larger area of hot metal could be exposed to the surrounding air. Now it was possible to control the temperature of the engine. If cooling air was supplied by a blower, the blower could be geared up to cool it faster. If cooling was provided by for ward motion alone (as with air-cooled bike engines) then the fin area could be increased to match a gain in horsepow er (as Harley did in the most recent Big Twin update).

Anyone who has ever boiled water knows that water has a high specific heat. It takes about 10 times as much heat to raise a gram of water one degree as it does to cause an equal temperature rise in a gram of iron. This means that water stores heat effi ciently, and so it can be used to trans port large amounts of heat. That's why high-output engines are liquid cooled-built with water-jacketed heads and cylinders. The water can collect heat directly from engine parts without fins or spikes, and can then be um~ed away to be cooled elsewhere.

EIS brings us back to the early hexagon-tube radiators and their problem of having equal water and air surface areas. One alternative was to pump engine coolant through a long tube, provided with fins by pressing thousands of thin metal washers over it. Many early cars had zig-zag arrays of this tubing as radia tors, and such are still used in home heating and in refrigeration.

Present-day engine-coolant radiators consist of a pair of tanks, connected by one or more rows of many thin water tubes. Having such multiple-path cool ing allows higher coolant flow than would be the case with a single, long, finned tube. Pressed over these tubes or soldered to them is a secondary sur face consisting of zig-zagging plate of foil thickness, evenly and narrowly spaced. Cooling air passes between these thin plates, whose aggregate area is huge. The plates are usually given a wavy shape because heat transfer is more rapid when flow is turbulent; the flow cannot become hot layers next to the metal, with a cooler layer flowing between them. Waste heat is efficient ly conducted from the water into the metal of the water tubes and thence by contact into the secondary surface of the thin plates pressed over them. In this way, the area presented to the

two fluids (air and water) is inversely proportional to their ability to carry heat. The result is an efficient heattransfer device, much better than a nail in a potato. It really should not be called a radiator at all, because it sheds far more heat by convection than it does by actual radiation (emission of infrared light). Must we therefore call it a convector? A water-to-air heat ex changer? Not wanting to be too stiff necked about correctness, I'm still happy to call it a radiator. The Ger mans, who are very direct about their engineering, just call it a cooler.

View Full Issue

View Full Issue