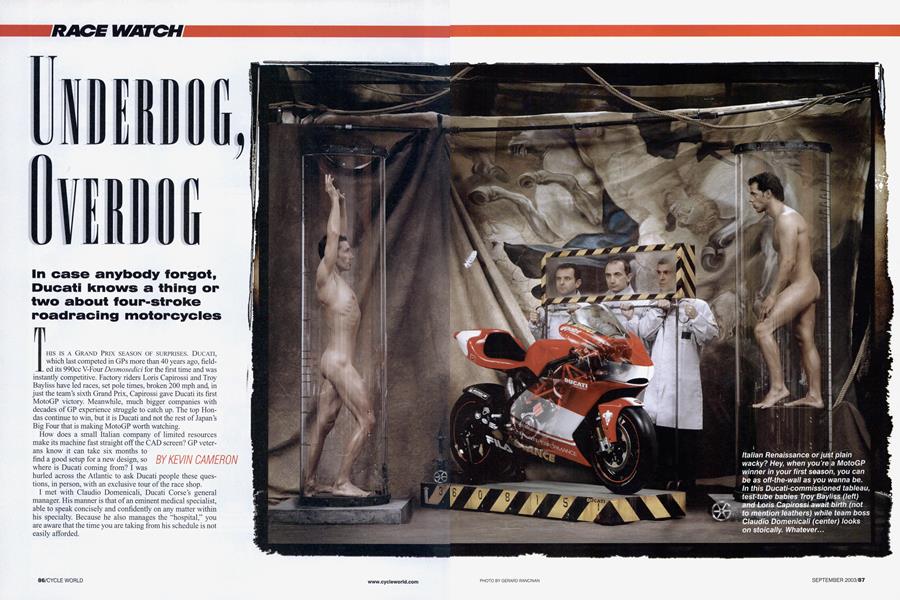

UNDERDOG, OVERDOG

RACE WATCH

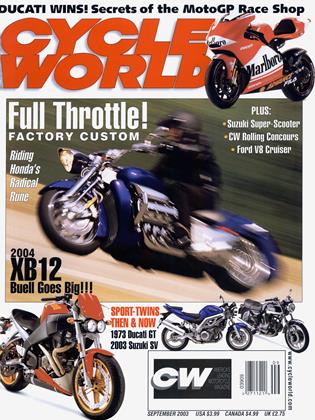

In case anybody forgot, Ducati knows a thing or two about four-stroke roadracing motorcycles

THIS IS A GRAND PRIX SEASON OF SURPRISES. DUCATI, which last competed in GPs more than 40 years ago, fielded its 990cc V-Four Desmosedici for the first time and was instantly competitive. Factory riders Loris Capirossi and Troy Bayliss have led races, set pole times, broken 200 mph and, in just the team's sixth Grand Prix, Capirossi gave Ducati its first MotoGP victory. Meanwhile, much bigger companies with decades of GP experience struggle to catch up. The top Hondas continue to win, but it is Ducati and not the rest of Japan's Big Four that is making MotoGP worth watching.

How does a small Italian company of limited resources make its machine fast straight off the CAD screen? GP veterans know it can take six months to

find a good setup for a new design, so

where is Ducati coming from? I was

hurled across the Atlantic to ask Ducati people these questions, in person, with an exclusive tour of the race shop.

I met with Claudio Domenicali, Ducati Corse’s general manager. His manner is that of an eminent medical specialist, able to speak concisely and confidently on any matter within his specialty. Because he also manages the “hospital,” you are aware that the time you are taking from his schedule is not easily afforded.

KEVIN CAMERON

“The decision to enter MotoGP was difficult for our management because there was naturally a chance that we might not be successful immediately,” Domenicali said.

“Costs and risks are high. Yet in the end there was really no choice. Ducati’s reputation depends upon success in racing, and to turn away from that challenge could only damage the company.”

He indicated that although threequarters of the $30 million budgeted by Ducati for MotoGP comes from outside sponsorship, the rest comes from within the company. The problem is to extract maximum bang from each dollar spent.

The engine of Ducati’s MotoGP design is a compact V-Four with gear-driven cams and-naturally-a desmodromic valve-control system. One cam lobe opens the valve and a second complementary lobe closes it, acting through levers. There are no valve springs. Those who have watched cockpit shots from this season’s GPs have seen the tachometer swing repeatedly beyond 16,000 rpm.

“We decided not to buy Formula One technology,” Domenicali explained. Here, “F-l technology” means pneumatic valves, in which valves are closed by gas pressure against small pistons rather than by springs.

rather than by springs.

“With metal valve springs, the practical maximum accelerating force that can be applied to the valve is 130 kilograms (285 pounds),” Domenicali continued. “With air springs, this is approximately doubled. Yet this large force occurs at full lift at all rpm-whether the engine is at the bottom of its powerband, at onehalf maximum revolutions or at the top of the rev band. This imposes a large burden of excess friction even when it is not needed. The desmo system applies the necessary force only as it is needed.”

By entering the world of ultra-rpm valve drive, Ducati’s desmo system has shown itself to be the equal of pneumatic systems-without their disadvantages.

Ducati therefore believed it already had the valve system its MotoGP entry would need. The money saved by using it could be spent on other work. In effect, Ducati’s decision to race MotoGP is a very carefully planned spread bet-as Boeing made when it developed the 707 and 747 aircraft. Like Boeing, they are “betting the company.” And so far, the odds look good.

Ducati Corse’s technical director is Filippo Preziosi, whom I found most impressive. His replies to my questions were as concise and structured as if he had taken a day to prepare them.

“The motorcycle designs itself,” Preziosi stated. “We place a rider in a position we know to be comfortable and workable. We add the wheels at a wheelbase we know to work well. We draw in front and rear suspensions according to best practice. This defines a space in which an engine must fit.

“Because we are working in CAD, we know accurately the weight of everything we are building. This allows us to achieve without experiment the weight distribution that we have found to work in the real world.”

Domenicali noted that although naturally tempted to make their MotoGP engine a Twin, its modeling on their engine software did not yield the necessary power margin. The alternative had to be equally compact, but able to rev higher. Logic dictated a shortstroke 90-degree V-Four. I was shown a crankcase model made by a rapid-prototyping machine. Pure white, it had the beauty of ivory.

Domenicali had characterized the D16’s (Desmosedici = Desmo 16-valve) bore/stroke ratio as “extreme,” and my eyeball micrometer suggested an 87mm

oore. I He `+ I ..llIllhl SiroKe tins iinpiies would reach 16,000 rpm at a moderate 4350 feet-per-minute piston speed-and leave room for development. I would lat er see D-16 engines in various states of assembly-360-degree crankpins, gear cam drives, bore-filling valves at a nar row included angle. They look just like the CAD images you have seen on Ducati's website. The entire rear suspen sion attaches to the engine, such that the "chassis" becomes just a bracket con necting steering head and engine. The packaging of components is so dense that Preziosi said of the machine, “There is not room for air-the motorcycle is full.” In roadracing, it’s traditional for setup decisions to be made between riders and trackside technicians. Engineerstraditionally regarded as too lofty (or too impractical) for such rough-andtumble situations-were responsible for hardware design. This creates a crippling information gap between trackside realities and design. Ducati management therefore required, beginning in 1999, that Ducati Corse put engineers into the trackside role, exposing them directly to the raw data of racing as is done in Formula One.

“Trackside people have been a valuable resource in getting the best from the existing motorcycle,” Domenicali observed, “but we also need this experience in order to design its replacement. For this, engineers are necessary. It is also necessary for engineers and riders to understand each other. This has been very difficult, but the value of putting engineers at trackside has begun to make the difficulties worth the trouble.”

Anyone with racing experience has seen crew members try to revise the laws of physics, and has seen academic engineers insist on theory that can’t work. To avoid both kinds of error is worth some difficulties.

I asked Domenicali about the apparent ease with which Ducati has changed bore/stroke ratio in recent years, remaining competitive each time (in World Superbike). Meanwhile, certain other makers have either had to revert to previous designs or have taken two or more years to make new engines competitive. Shorter strokes tend to slow combustion speed by making the combustion chamber too tight for rapid charge motion.

“Our combustion model spans a good range of (maximum) rpm, beginning with the 11,000 rpm of the production Superbike, and extending to more than 16,000 in the Desmosedici. The valve size, the angle of the intake port to the cylinder axis, and other variables influence air tumble motion in the cylinder. We measure and control all of these.”

A crisis for other makers is all in a day’s work at Ducati? The previous day, I had been shown a honeycomb element used to measure in-cylinder air motion-the most affordable of several available techniques.

Preziosi outlined the basic problem of building a competitive machine.

“The three most important elements of a racing motorcycle are not under the constructor’s direct control. These are, in their approximate order of importance: the tire, the rider and the suspension. We could argue about tire versus rider, and perhaps Valentino Rossi is a

special case, but these three elements are available equally to all. This compels the constructor to seek his advantage in variables of lesser influence.

“For example, imagine that an improved camshaft profile results in an increase of 5 horsepower. What is the result when track tested? The test rider says, ‘It makes no difference,’ or ‘It’s a bit better’ or ‘A bit worse.’

“But at best, the stopwatch shows a decrease of .02-second per lap. It’s a hot day at the track and the rider’s lap times are varying by twice this much. Changes in track and tire condition introduce more variation. Thus, not only may the positive result of a 5-bhp gain be unproven, but changes to even lesser variables will actually be invisible.”

Famed Moto Guzzi designer Dr. John Wittner has said of Ducati that, “They never stop testing,” so it’s clear they intensely pursue the practical.

Earlier in my visit, Domenicali had revealed the existence of their two-yearold computer vehicle dynamics model, and the effort put into it. His remarks complemented those of Preziosi. He noted that the model may, given sufficient development, allow the variability of real rider, tire and weather to be removed from a simulation. Then, the positive or negative effects of even quite small alterations-he gave the example of a small movement in engine position-could be discerned. Five such changes, each of which would be invisible in actual track testing, might thus be assessed in the dynamic model, and their effects together might be large enough to see in actual track testing.

This is very ambitious because twowheeled modeling is a vast and tricky subject, but it symbolizes the changes now in progress at Ducati. Beginning with the large accumulated experience base in 1999, Domenicali and Preziosi clearly plan to build upon that by use of the most modern analytical methods. Bigger companies are better able to pay for such things, Dut-Ducati s experience can save them from the wilder temptations of theory.

I asked Preziosi about possible future radical solutions.

“My greatest fear is that of 100 ideas presented to us here by inventors and others, I will send away the one which has real value,” he explained. “The telescopic fork is the most stupid idea possible for supporting the front of a motorcycle. Yet because of the development it has received, no alternative has thus far been able to equal its performance. Many ideas are possible, but there is only limited development money. Responsibility obliges us to deal in certainties-improvements to what we already understand.”

Preziosi said that technology development at Ducati is written up in report form and circulated to all. This keeps engineers aware of problems in other areas with possible effects on their work.

“Of course, one of my people could leave-perhaps to Aprilia-and would surely take with him his notes and such reports. This would represent a loss of our technology, but on the whole, the advantages outweigh the difficulties.”

This echoes the opinion of former Goodyear President Paul Litchfield, who held that, “Secrecy tends to keep more information out than it keeps in.” Preziosi continued, “We have a way of working here at Ducati that is unique in Italy. Some of the time we behave in a traditional Italian way, speaking at high volume, perhaps even screaming. But we also know who is the boss, each person knows what he is supposed to do and what he must not do. When a part fails and the engineer who designed it comes in, I say to him, ‘You did not just design this part. You are its father, it is your child. Until it works as it should, you should not be sleeping at night.’” Working at 100 percent risks personal burnout. Domenicali stressed the need to balance work and personal life, to restore the mind by alternating work and other activities. He spoke of engineers working in a “flux state,” remaining excited and stimulated to be designing important parts for a project important to all.

“We have brought in many very> young people and they have grown up with us in a way of working,” he said.

Earlier, I had toured part of the operation with the company’s grand old man, Gianluigi Mengoli, veteran of 29 years, and an accomplice of Massimo Bordi during Ducati’s internal revolution. Together they brought Ducati into the modern world of four-valve engines and quicker-steering chassis.

As Mengoli reached to open a door, a young engineer burst out through it, nearly knocking him down. The young man, seeing whom he had hit, covered his face with his hands, murmuring apologies. Mengoli put his arm around him, grinning, and told him there was nothing wrong with being in a hurry. Earlier, a younger engineer had exclaimed, “He can spot a bad dimension on a drawing from meters away!” Another added, “And God help you if your drawing is black with too many dimensions-Mengoli will come and demand to know the reason for every one! He wants it simple-easy to understand.”

Clearly, these men hope to become like him one day. Ducati’s engineering team has some of the qualities of a family.

Ducati Corse operates like a simple machine with low internal friction. People know their jobs and the work is exciting. Long ago, the company learned how to win races, and management has never tried (as others have) to switch racing on and off. Every day something new is added, and nothing is forgotten. Modern methods are expanding but don’t overshadow the practical.

All this makes Ducati’s success understandable. But how do organizations with much greater resources fail? For a possible answer, I thought of the 1950s, the golden age of military aviation when nervous governments gave aerospace a blank check. The natural big> company response to winning a major contract was, “We’ll put a thousand engineers right on it.”

Strangely, the bigger the team, the less it accomplished. Slowly, it became clear that to accelerate progress, you had to take engineers off the project, not add more. To get things done quickly, the team had to be small, efficient and well informed. This was the origin of Lockheed’s famed “Skunk Works” development group, which produced such remarkable aircraft as the U2 and SR-71. Cartoonist Scott Adams depicts life in “Cubeville”-the employee cubicles of today’s tightly managed high-tech firms. Big program behind schedule and over budget? Set more meetings! Appoint fault-finding committees! Hire consultants, then argue with them! Still behind? Set goals and measure progress with metrics-objective” measures of accomplishment. To isolate problems, departmentalize. Choose new leaders-not for engineering ability but for their departmentalizing skills. Now the deadly “Law of Uncommunication” requires that the number of daily meetings becomes equal to the square of the number of departments. What’s happening? Like an engine revved too high, this company’s internal friction limits its output.

Maybe very large organizations can succeed with the meetings-anddepartments method. New cars do get produced, and men once traveled to the moon and returned safely to earth. But applying such methods to smaller firms-and particularly to racing-just seems to generate more friction. This makes Ducati’s way all the more impressive. □

View Full Issue

View Full Issue