Unfinished Business

THE TWIN THAT COULD HAVE BEEN

KEVIN CAMERON

CAN WE HAVE IT?" THOSE WORDS, SPOKEN BY EDITOR-IN-CHIEF DAVID EDWARDS, SET this story in motion. Having reverted to a GSX-R750-only Superbike program for 1999, Suzuki had put the exotic race version of its TL1000R V-Twin on the show circuit. In journalism, as in love, YOU get nothing if you don't ask. And when Edwards asked, the Suzuki people smiled and said, "Sure."

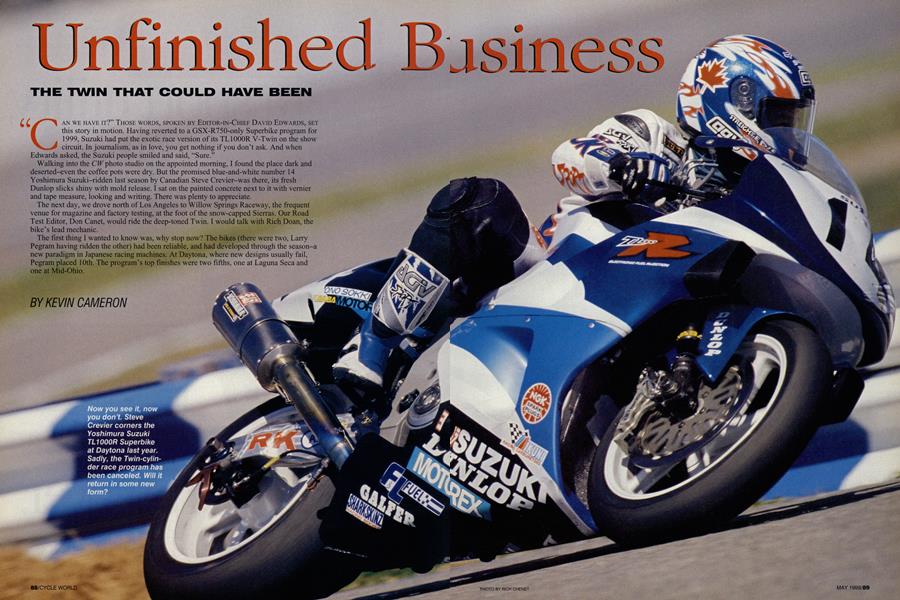

Walking into the CW photo studio on the appointed morning, I found the place dark and deserted-even the coffee pots were dry. But the promised blue-and-white number 14 Yoshimura Suzuki-ridden last season by Canadian Steve Crevier-was there, its fresh Dunlop slicks shiny with mold release. I sat on the painted concrete next to it with vernier and tape measure, looking and writing. There was plenty to appreciate.

The next day, we drove north of Los Angeles to Willow Springs Raceway, the frequent venue for magazine and factory testing, at the foot of the snow-capped Sierras. Our Road Test Editor, Don Canet, would ride the deep-toned Twin. I would talk with Rich Doan, the bike’s lead mechanic.

The first thing I wanted to know was, why stop now? The bikes (there were two, Larry Pegram having ridden the other) had been reliable, and had developed through the season-a new paradigm in Japanese racing machines. At Daytona, where new designs usually fail, Pegram placed 10th. The program’s top finishes were two fifths, one at Laguna Seca and one at Mid-Ohio.

Doan'sanswer surprised~me; man power. He said Suzuki's racing depart ment in Japan mimbe only 25-45 peopi~-not enough to ser~~ 250 and 500cc Grand Pnx, Superhike and the TL-RproieetOiie prögiam had to go,

and so it was last in, first out.

Over the past two tltcades,, w&ve• often heard factory race mechanics describe themselves as s-changers, with tuning limited to techniques of opening, crates. air-shipped from facto ry R&D centers. Not at Yosbimura. Suzuki AMA entries, Doan tod me, are assembled here, from parts. This is the complete antithesis of parts-chang irg. Race engine builder is not just another profession that's been sent e0 shore by NAFTA.

When Yoshimura began racing AMA Superbikes inthe late 1970s, its crew-often including homesick young: Japanese-worked incredible hours, fre quently around the clock. Today, it is recognized that people cannot do con sistently good work in. that kind of cri~ sis atinospb~re. Professionals like

Doan work normal hour, and enough qualified people are hired to make that possible.

Doan gave me snippets of days in the life of a factory team-the big parts order arriving, the need to get 10,000 items into stock, but also to get a bare crankcase to the man who needs it right now, tappets to another, pistons to a third, all while keeping book on what has come, where to look for it and what is needed next. New mechan ics need guidance, tests have to be planned and some lucky person has to clean out the truck-and know why he's doing it. When Japanese engineers are in town, there is the delicate cross-cul tural task of' explaining current prob lems-and making suggestions with the kind of diplomacy that allows the visi torto beii~ve they are his ownideas. Can we make all external fasteners 8mm, so most jobs require one 1-han dle? Which rider r VIP has to be picked up in front of baggage claim? There is a lot more to being a race mechanic than being an ace with a torque wrench.

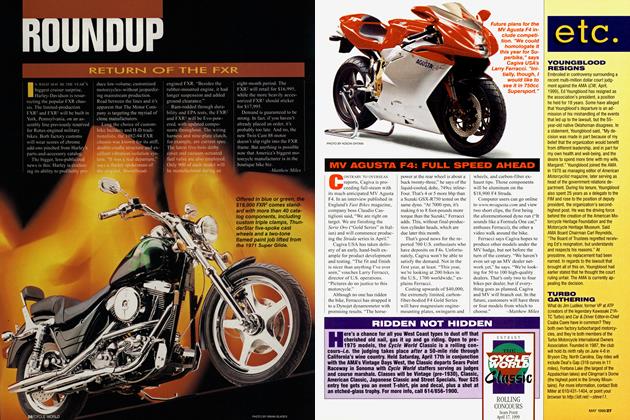

Up close, the first impression of the TL-R is of length and bulk. Two hefty 20-inch silencers rise like howitzers to the rear, whil.e the carbon-fiber fairing runs 6 inches ahead of the front-axle centerline. Jutting, 2 x 5-inch-section "lobster-claw" rain-air intakes projuct on either side. But, in fact, the wheel base is a short 55.75 inches to the adjustment midpoint. The long look is an illusion. The hefty swingarm's 21.75-inch length is a tribute to. the engine's fore-aft compactness.

engine’s compactness.

Weight? On the limit, at 363 pounds. The 90-degree V-Twin is, like the Ducati 996, Harley VR1000 and Honda VTR1000F, of 98 x 66mm bore and stroke. While the Ducati has its front cylinder horizontal, the TL has its raised considerably, with a lowered exhaust cam, to allow the engine to be pushed closer to the front tire. To do this, the coolant radiator is split into two curved pieces-an 18-inch-wide upper and a smaller, more triangular lower, with the front cambox appearing through a small slot between them.

The dashboard display includes a tach, redlined at 11,700 rpm, with a display window through which five variables can be scrolled. On the left is the Pi Research data-acquisition display, which can show lap times. In terms of piston speed, Twins reach frightening numbers. Eleven-seven in this case is more than 5000 feet per minute. At redline, both ignition and fuel cuts occur.

The engineers told Doan that the valve springs are the first parts to show distress at even higher rpm-the titanium con-rods and light pistons are happy to rev on. In any case, it is peak piston acceleration, and not piston speed, that is responsible for stress in reciprocating parts. Doan said the engine pulls strongly from 6000 rpm, torque peaks at about 8500, and peak power comes in the range of 10,200-10,500. Yes, Ducatis are allowed to rev higher, but their peak power has typically been given in the 10,200-10,800 range. No mysteries here.

Canet did only a few laps on the Twin, finding that its Las Vegas Motor Speedway setup, with hard springing and damping, gave excessive steering kickback and busyness at Willow. This was so even with the wide clip-ons, measuring 27 inches, tip-to-tip. At the beginning of the year, the team had to find a working chassis/suspension setup where none existed. Doan revealed that, with the separate levers and links for rear spring and rotary damper alone, there are more than 3000 possible combinations. Add rider preferences to that: Crevier likes a rising rear suspension rate, while Pegram likes it linear. Numbers like these make the setup problem seem worse than it really is. Basic rear-suspension variables are the initial spring and damping rates at the axle, and the general shape of the rate curves for each. Finding something that will work doesn’t mean testing every possibility.

Early in the season, development moved rapidly. New-design pistons arrived three or four times, and each time, Doan noted, the result was a better fit to the head, and an improved bum pattern. With the need to run races, test time was limited, but the team piled up miles rapidly. Cam timing ended up near 105-degree lobe centers for both intake and exhaust-without the ability to alter fuel and ignition curves, more experimentation was pointless. Racing and development don't really go togeth er unless you have a dyno team and a track team, Doan observed. Everything costs money and there isn't time to test every good idea.

Basic engine reliability was excel lent. This is a strong point with all Japanese race engines: Their testing is

based upon the same methods used in developing new models, and the testing is evidently relentless. Very seldom do you see an actual failure in the field. Stock camchain tensioners occasionally popped back, and were replaced with less convenient but more rugged manu al-adjust types that never failed. I asked Doan about engine bearings: "The rod bearings. ..looked like bearings (that is, they develop streaks and pick up debris as all plain bearings do). But the mains, they always looked like they'd never been touched-perfect." With leaded gasoline still used in AMA racing, compression can safely be up at high numbers that give power ful torque. The TL-R's 13.6:1 corn-

pression ratio made starting difficult-until dirt-tracker Pegram showed the team how to do it. With the gearbox in sixth, and the bike on a rear

stand, he manually pulled the rear tire back so the engine was on the long interval (firing angles are 270/450). Then, with someone holding the clutch, he trundled the starter (a Briggs & Stratton motor with a small tire on its output shaft) up against the rear tire and spun it up “until it was making that high whistling sound,” and dropped the clutch hard, “No gradual engagement-just dropped it.” With all that momentum in the rear wheel, and the full 450 degrees of crank rotation available before hitting compression, it would start every time.

Break-in? “We just started them up and let them idle for a long time,”

Doan said. No break-in oil or special procedures were used-just the standard 0-30W wide-range multi-grade race oil. Engine operating temperature is normally 75 degrees Celsius (167 degrees Fahrenheit). If the desired oil temperature is not reached because of cold weather, the radiator is taped to raise it. Oil cooling is by an oil-towater cooler under the tiny spin-on filter at the front of the engine. Water from a two-outlet pump on the right side of the engine cools cylinders and heads, then exits in the cylinder vee, returning to flow across the top rad, then down to loop across and back in the chin rad, exiting back to the pump.

We were allowed to remove the fairing and tank for photography, but not the top of the airbox. This compact carbon-fiber box appeared to be of about 8-10 liters in volume, served by the two large intakes. Where Harley’s VR always loses power when the airbox is put on, the TL lost power when it was removed. As one would expect, there are two injectors per stack-one below the butterfly throttle for lowand mid-rpm running, and a top injector for higher rpm.

One item added during the season was an oiled-foam air filter. Doan noted that horsepower would fade prematurely from debris being hammered into the valve seats. This resulted from the unusually low position of the two air intakes. Once a suitable filter was developed, power remained high for much longer.

Front suspension is by a massive Kayaba 46mm inverted fork. Here again, rider preferences emerge.

Pegram liked the more flexible magnesium four-bolt lower crown with all four bolts in place, but Crevier liked a six-bolt aluminum crown with only the top four bolts in place. Lots of playing with chassis flex goes on today, and this is but one place it occurs. As it sat in our studio, the machine had a 30mm offset. Offset is the distance from the steering axis centerline to a plane through the centers of the fork tubes. Offset changes are used to adjust steering trail-the smaller the offset, the greater the trail. Canet noted the ring spacers between the fork legs and steering crown; they allow other types or makes of fork legs to be used. More setup variables!

All the parts are of the finest craftsmanship-lovely to behold-from the twisting, snaking, tapered titanium exhaust system to the 6-inch-diameter dry clutch, to the multitude of CNCmilled pieces everywhere. Once you work with factory racebikes, streetbikes seem coarse and unsatisfying. No wonder the aftermarket in carbon fiber, titanium and billet parts is so lively. Both sides of the TL-R's engine sported magnesium covers with the fashionable brown surface treatment. Untreated mag soon weathers to a blotchy gray.

wnat aDout tne controversial icaya~a rotary rear damper-in this case a gem of billet milling? Doan explained that with updates, it improved steadily. The 80mm-diameter housing contains a rotary vane pump that uses suspension motion to force oil through the piggy back compression/rebound valve body. There is as yet too little accumulated

experience to compare it with the best tubular units. It is certainly compact.

As always, wheels, suspension and brakes are an international Lego set. This bike sported 17-inch front, 16.5inch rear Italian Marchesini five-spoke wheels-the current GP standard-with a pair of English AP milled-from-solid six-piston front brake calipers acting on 320mm iron discs, which are 6.2mm thick.

Doan said early in our conversation that the Twin’s vibration broke unusual parts at first-things that had never broken on a 750cc inline-Four. He attributed this to lower frequencies exciting different parts. As with any race machine, anything that breaks is either improved in design, or is listed for routine replacement on an appropriate schedule. A 90-degree V-Twin has good primary balance (the onceper-revolution frequency), but has a fair secondary imbalance (twice-per revolution) that would be at about 75 percent of the frequency generated by

a 750. The wine glasses that break depend on the note you sing, and how loudly you sing it.

Modem racebikes are covered in electronics. From the engine-control computer in the fairing nose and from the Pi computer under the seat, a network of wires and sensors runs everywhere. When something fails, an error code appears in one of the windows on the dash. What do you do in the middle of Willow’s ultra-fast Turn 8 when you get a “file does not exist” or “you’ve got mail?”

Is there something to the idea of “Twin traction?” Do the wider-spaced power impulses of a Twin act like a Big Bang GP two-stroke, and thereby enhance rear-wheel grip during offcomer acceleration? Riders believe it. Using 9000 rpm and accelerating at 60 mph, the Twin’s 150 power pulses per second satisfy the criterion that the rear tire must lay down a fresh, unstressed footprint for each pulse. These numbers give us 7 inches of forward motion between pulses (that’s an average-the actual 270/450 firing order gives us 5.25 inches and 8.75 inches, alternating). And Doan said the Twin does accelerate harder than the 750s, and has something less on top-end.

So many possibilities, so little time. To see this machine, which acquitted itself well in terms of reliability and speed, get only one year of development, against the accumulated knowledge of Ducati’s 14 seasons, saddens me. I don’t normally associate emotions with machines-machines are just physical expressions of people’s ideas at a given moment-but in this case, I feel it. One roll of the dice, one mn through the possibilities, isn’t enough.

I wanted to see Eastern and Western Twins, head-to-head.

The TL-R hadn’t mn since the last AMA National at Vegas, and was adorning an office at Suzuki. The Yosh men put in a fresh battery, wheeled up the starter, and it fired and ran. Now, it goes back to the office. □