Acceleration II

TDC

Kevin Cameron

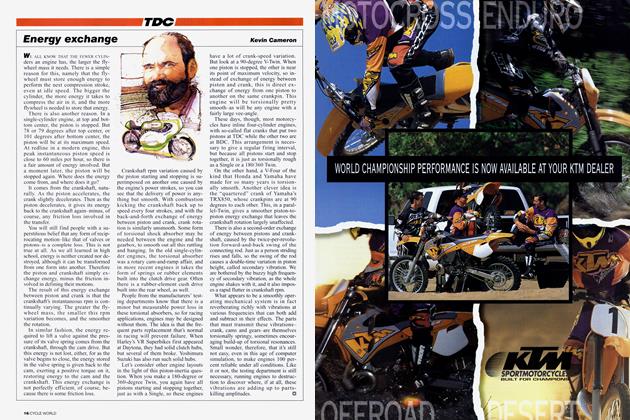

WHEN INTERNAL COMBUSTION (IC) ENgines were first built, their piston-sealing rings were borrowed from an obvious place—the steam engine. This so-called "Ramsbottom ring" persists to this day, consisting of a springy metal ring with a gap in it. Placed in a groove on the piston and then compressed to fit into the cylinder bore, this ring expands to seal tight against the cylinder. Leakage at the ring gap is small, and can be further reduced by adding more rings.

The sealing problems of steam and IC engines evolved in different directions. Most steam engines were double-acting-that is, steam was admitted on first one side of the piston, then the other, alternately. Springs and wedges were used to make rings seal both ways. Combustion in the IC engine (save for some unique double-acting diesels) occurs only on the crown side of the piston. Steam engine rings had to seal in both directions, but IC engine rings only had to seal one way.

It was soon found that the sealing of IC engine piston rings could most efficiently be accomplished by the gas pressure of compression and combustion, pressing the ring down against the bottom of its groove, and outward against the cylinder wall. While the ring’s own natural springiness is useful to provide compression for starting, it only exerts a few tens of psi of outward pressure. This is only a small fraction of compression and combustion pressures.

In order for the ring to employ gas pressure to seal, that pressure has to get into the crevices above and behind the ring. More than one engine builder has had the experience of inadvertently assembling an engine with too little up-and-down clearance of the top ring in its groove. With too tight a pathway for the “inflation” of the ring, the faster the engine runs, the worse the seal gets because there is less and less time in which gas pressure can fill the crevices to pressurize the ring. The result is mysteriously disappointing power. In the shops of these builders, you will find puck-shaped tools, machined with circular recesses to hold rings as they are lapped on fine abrasive paper to adjust this clearance.

The developing IC engine soon outgrew its early rings, which were wide and heavy like those of steam engines. Wide rings tended to break at higher rpm. Making the rings vertically thinner usually prevented this, and rings have been getting thinner ever since-those on recent sportbike engines are now down around .8mm. Narrow rings also reduce friction, because they reduce the area over which combustion pressure is acting through the ring, loading the oil film on the cylinder wall.

Ring breakage was ascribed to a type of radial vibration of the ring, called “flutter” in a paper by a gentleman named Paul Dykes. As the piston and rings decelerate approaching TDC on the compression stroke, gas pressure from compression and combustion enters the ring crevices through the top clearance. At the same time, inertia tends to lift the ring off the bottom of its groove; piston deceleration in current sports engines reaches 4000 g, and in some race engines, 7000 g. Thus, the question of whether the ring remains held on the bottom of its groove by gas pressure, or whether inertia lifts it off, is determined by how fast the ring can be pressurized. If the ring does lift off, it loses all pressurization and collapses inward. It may then break under repeated cycling.

Although those acceleration figures are impressive, my numbers show that it takes less than 50 psi above a 1mmthick ring to hold it in place against 4000 g of near-TDC deceleration. Even if the engine is not firing, you’d think that the 175-200 psi of compression alone would do the job handily.

That it sometimes does not indicates that the process of ring inflation takes time. Of course, the deceleration of the piston by the con-rod is not the only acceleration at work. Somewhere around TDC, the piston changes sides in the bore as the con-rod swings past the vertical, and this adds its own jolt.

Let’s consider the opposite-how long it takes pressure to come back out of the ring crevices once they are pressurized. In some fine research done at MIT, Professor John Heywood et al were able to show that crevice outflow can in some cases persist all the way to the intake stroke. Why does it take so long? Because the flow path is long and narrow, extending across the top of the ring at a clearance of about ,05mm, then up between the cylinder wall and the top ring land at possibly a closer clearance.

Note that the upper surface of the ring cannot become uniformly pressurized until any volume at the back of the ring has also come up to pressure. Pressure above the ring is an average of pressure at the cylinder wall and pressure at the back of the ring. This is why ring grooves are designed with minimum back clearance-so it will take minimum time to fill and pressurize. Likewise, in high-rpm engines, piston designers go to fanatical lengths to be able to raise the top ring and thereby shorten the flow path. The higher the ring, the hotter it runs, and the faster it and its groove wear. Undaunted, designers anodize the ring grooves to harden them, allowing the ring to survive closer to the fire.

Why not just drill holes from the piston crown, down to the back of the ring, as drag engine builders have done? No matter how big you make a hole, it leads to a tight space that is itself the flow bottleneck. This is identical to the problem of sizing con-rod journal oil holes; the actual flow path is the hole’s circumference times the tiny bearing clearance. There is no easy solution in drilling holes, which in any case weaken the piston.

With their constant inflow and outflow of gas pressure, piston rings can be said to “breathe”-they pressurize and depressurize every two revolutions. If rpm leaves this breathing process behind, then sealing-and power-deteriorate. □