No sharp corners

TDC

Kevin Cameron

THE MOST BEAUTIFUL PARTS ARE THOSE I call “highly evolved." By that I mean that the parts have been through several cycles of failure and redesign, each time coming closer to an ideal shape and material.

Such parts evolve in response to difficult applications where failure is likely. Here by my keyboard is a big forged piston (over 6-inch diameter) from a supercharged aircraft engine of the 1950s. Its unique quality is its nearly uniform thickness everywhere, with no sharp angles or edges. It is as though some giant child had formed it from a big sheet of modeling clay, first making a cup, then pushing in the sides, then dimpling and piercing them inward to form the wristpin bosses. Each boss is then fused to the dome by short pillars that are machined to graceful roundness. This is a part evolved to cope with combined thermal and mechanical stress. There are no big lumps of metal whose expansion would pull or push the rest of the part out of shape. The smooth curves allow stress in one area to feed smoothly into other regions, without concentrating at angles and corners.

As it comes from the forge, a forged part is always simplified by the fact that the male die must pull straight out of the part. Thus, any re-entrant shapes or undercuts must be machined afterward. In this big piston, clever use has been made of such machining to maintain near-constant thickness, consistent with the desired shape.

Looking at this part, I remembered with still-active annoyance the pistons in our air-cooled two-stroke racebike in the summer of 1973. As in the aircraft piston, excess metal had been machined from beneath the wristpin bosses to avoid local heat-expansion problems. This cutting left sharp edges on each pin boss. As I and others on that long-ago race team tore the engine down one evening in Texas for postpractice inspection, we naturally examined the pistons. On each sharp edge, under each machined wristpin boss, was a tiny, deadly crack.

On the aircraft piston, in the exact region where corresponding cracks might be expected, the pin bosses are machined to a smooth, rounded contour. free of sharp edges. No cracks for thousands of hours. Remarkable.

It's not that the designer of the aircraft piston was smarter. It is that he'd been exposed to more cycles of failure and redesign, and the ideas that had finally worked did not include sharp edges. Experience with exploded race engines caused by 2mm cracks makes you appreciate things like that.

The designer of the aircraft engine piston had experience because the power of those engines was increased constantly, year by year, as development proceeded. Testing to destruction was a rational development tool imposed on aircraft engine builders by the U.S. Navy back in the 1920s, and it remains just as valuable today.

Another difference between these two pistons is in the wristpins themselves. In the motorcycle piston, the pins are long, to feed stress from the con-rod in the middle, clear out to bosses built into the sides of the piston skirt. This made it “bendy." On the aircraft piston, the pin is shorter and fatter in proportion. The short pin is accommodated by pushing the sides of the piston inward. Each wristpin boss is fused to the dome above, making a direct, rigid stress path for combustion force to be carried from piston dome to pin boss, into the pin and con-rod. There are no drilled oil holes to act as “dotted lines" that invite cracking. Yamaha (and later, others) adopted this sensible plan on MX pistons in the 1970s. A short, fat. stiff pin bends less, so pin boss stress is reduced. No cracks.

A similar design style is seen in current E-l auto-racing pistons—short pins with bosses joined directly to the dome-and in BMW's big-bore 1100 Hat-Twin. Similar conditions invite similar solutions.

Under a pile of stuff off to my right stands a big air-cooled cylinder, also from an aircraft engine. Its 155 cubic inches were held down on the crankcase by 16 studs through a steel base flange forged in one piece with the liner. To a person who has seen many cylinders broken off motorcycle engines by failure of base flanges, this is interesting. The flange blends into the liner in a smooth, generous fillet, without any sharp edges that would concentrate stress. Where the flange is spot-faced to provide seats for each of the 16 holddown nuts, the flat seats sweep up into the rest of the flange-also in graceful, smooth curves. But in nearly every case of broken base flanges on motorcycle cylinders, the cracks can be seen to have originated in sharp corners left by (a) inexperienced designers who had not yet seen and thought about enough broken parts or (b) underfunded designers whose corporate CEOs were too cheap to specify radiused cutters. In recently designed base-bolted motorcycle cylinders, you will see smooth fillets and no sharp corners.

At the recent SAE motorsports meeting in Detroit, I had the opportunity to examine a variety of aftermarket cylinder blocks made for auto racing use. It was pleasing to see that intersections of surfaces were implemented with smooth curves rather than the traditional mass-production sharp corners. This is surely the result of combined design experience (racers break lots of parts) and the current use of computer modeling. Racing experience is valuable even to non-racing manufacturers because it provides a severe environment-accelerated testing of just the sort that made those aircraft pistons run 3000 hours.

Whether a given design is achieved through experience or computer modeling. the resulting parts must still be validated in the old way, by testing to destruction in actual operation. Computer models aren't pcrfect-if they were, the weather forecast would always be correct-but their use by experienced designers can reduce the necessary number of test/break redesign cycles it takes to achieve a durable part.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontRamblings

March 1995 By David Edwards -

Leanings

LeaningsMotorcycling For the Duration

March 1995 By Peter Egan -

Letters

LettersLetters

March 1995 -

Roundup

RoundupPorsche Building A Bike?

March 1995 By Robert Hough -

Roundup

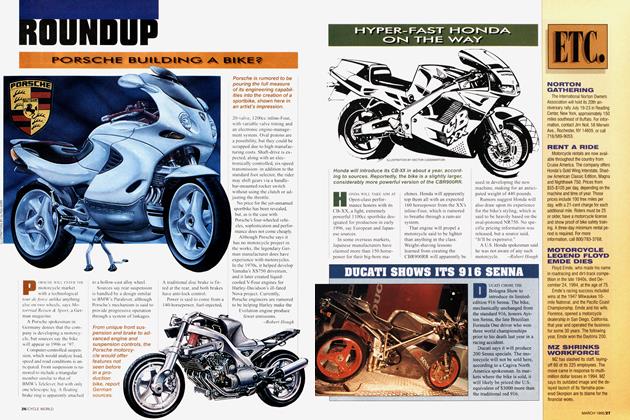

RoundupHyper-Fast Honda On the Way

March 1995 By Robert Hough -

Roundup

RoundupDucati Shows Its 916 Senna

March 1995