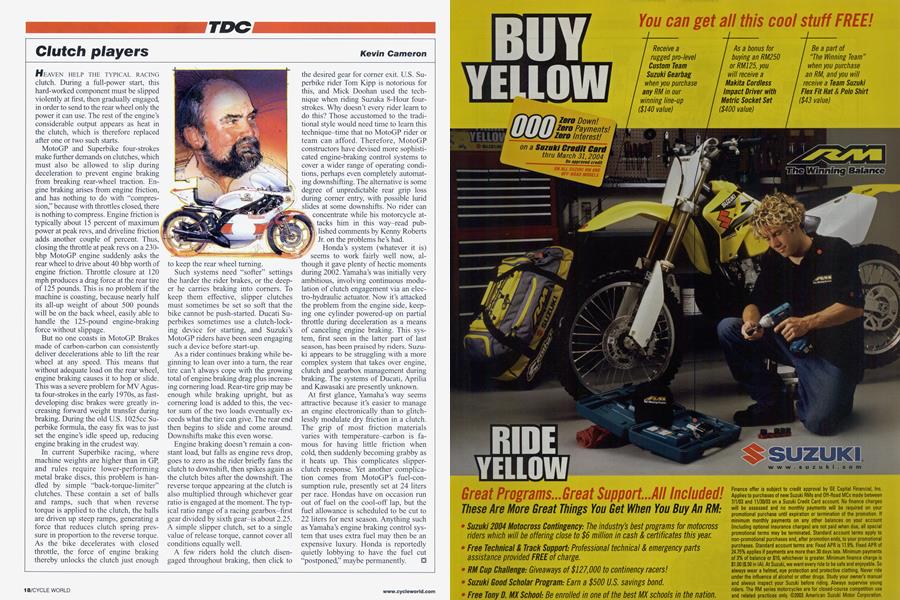

Clutch players

TDC

Kevin Cameron

HEAVEN HELP THE TYPICAL RACING clutch. During a full-power start, this hard-worked component must be slipped violently at first, then gradually engaged, in order to send to the rear wheel only the power it can use. The rest of the engine’s considerable output appears as heat in the clutch, which is therefore replaced after one or two such starts.

MotoGP and Superbike four-strokes make further demands on clutches, which must also be allowed to slip during deceleration to prevent engine braking from breaking rear-wheel traction. Engine braking arises from engine friction, and has nothing to do with “compression,” because with throttles closed, there is nothing to compress. Engine friction is typically about 15 percent of maximum power at peak revs, and driveline friction adds another couple of percent. Thus, closing the throttle at peak revs on a 230bhp MotoGP engine suddenly asks the rear wheel to drive about 40 bhp worth of engine friction. Throttle closure at 120 mph produces a drag force at the rear tire of 125 pounds. This is no problem if the machine is coasting, because nearly half its all-up weight of about 500 pounds will be on the back wheel, easily able to handle the 125-pound engine-braking force without slippage.

But no one coasts in MotoGP. Brakes made of carbon-carbon can consistently deliver decelerations able to lift the rear wheel at any speed. This means that without adequate load on the rear wheel, engine braking causes it to hop or slide. This was a severe problem for MV Agusta four-strokes in the early 1970s, as fastdeveloping disc brakes were greatly increasing forward weight transfer during braking. During the old U.S. 1025cc Superbike formula, the easy fix was to just set the engine’s idle speed up, reducing engine braking in the crudest way.

In current Superbike racing, where machine weights are higher than in GP, and rules require lower-performing metal brake discs, this problem is handled by simple “back-torque-limiter” clutches. These contain a set of balls and ramps, such that when reverse torque is applied to the clutch, the balls are driven up steep ramps, generating a force that reduces clutch spring pressure in proportion to the reverse torque. As the bike decelerates with closed throttle, the force of engine braking thereby unlocks the clutch just enough to keep the rear wheel turning.

Such systems need “softer” settings the harder the rider brakes, or the deeper he carries braking into corners. To keep them effective, slipper clutches must sometimes be set so soft that the bike cannot be push-started. Ducati Superbikes sometimes use a clutch-locking device for starting, and Suzuki’s MotoGP riders have been seen engaging such a device before start-up.

As a rider continues braking while beginning to lean over into a turn, the rear tire can’t always cope with the growing total of engine braking drag plus increasing cornering load. Rear-tire grip may be enough while braking upright, but as cornering load is added to this, the vector sum of the two loads eventually exceeds what the tire can give. The rear end then begins to slide and come around. Downshifts make this even worse.

Engine braking doesn’t remain a constant load, but falls as engine revs drop, goes to zero as the rider briefly fans the clutch to downshift, then spikes again as the clutch bites after the downshift. The reverse torque appearing at the clutch is also multiplied through whichever gear ratio is engaged at the moment. The typical ratio range of a racing gearbox-first gear divided by sixth gear-is about 2.25. A simple slipper clutch, set to a single value of release torque, cannot cover all conditions equally well.

A few riders hold the clutch disengaged throughout braking, then click to

the desired gear for comer exit. U.S. Superbike rider Tom Kipp is notorious for this, and Mick Doohan used the technique when riding Suzuka 8-Hour fourstrokes. Why doesn’t every rider leam to do this? Those accustomed to the traditional style would need time to learn this technique-time that no MotoGP rider or team can afford. Therefore, MotoGP constructors have devised more sophisticated engine-braking control systems to cover a wider range of operating conditions, perhaps even completely automating downshifting. The alternative is some degree of unpredictable rear grip loss during corner entry, with possible lurid slides at some downshifts. No rider can concentrate while his motorcycle attacks him in this way-read pub¡ lished comments by Kenny Roberts f Jr. on the problems he’s had.

Honda’s system (whatever it is) seems to work fairly well now, although it gave plenty of hectic moments during 2002. Yamaha’s was initially very ambitious, involving continuous modulation of clutch engagement via an electro-hydraulic actuator. Now it’s attacked the problem from the engine side, keeping one cylinder powered-up on partial throttle during deceleration as a means of canceling engine braking. This system, first seen in the latter part of last season, has been praised by riders. Suzuki appears to be struggling with a more complex system that takes over engine, clutch and gearbox management during braking. The systems of Ducati, Aprilia and Kawasaki are presently unknown.

At first glance, Yamaha’s way seems attractive because it’s easier to manage an engine electronically than to glitchlessly modulate dry friction in a clutch. The grip of most friction materials varies with temperature-carbon is famous for having little friction when cold, then suddenly becoming grabby as it heats up. This complicates slipperclutch response. Yet another complication comes from MotoGP’s fuel-consumption rule, presently set at 24 liters per race. Hondas have on occasion run out of fuel on the cool-off lap, but the fuel allowance is scheduled to be cut to 22 liters for next season. Anything such as Yamaha’s engine braking control system that uses extra fuel may then be an expensive luxury. Honda is reportedly quietly lobbying to have the fuel cut “postponed,” maybe permanently. □

View Full Issue

View Full Issue