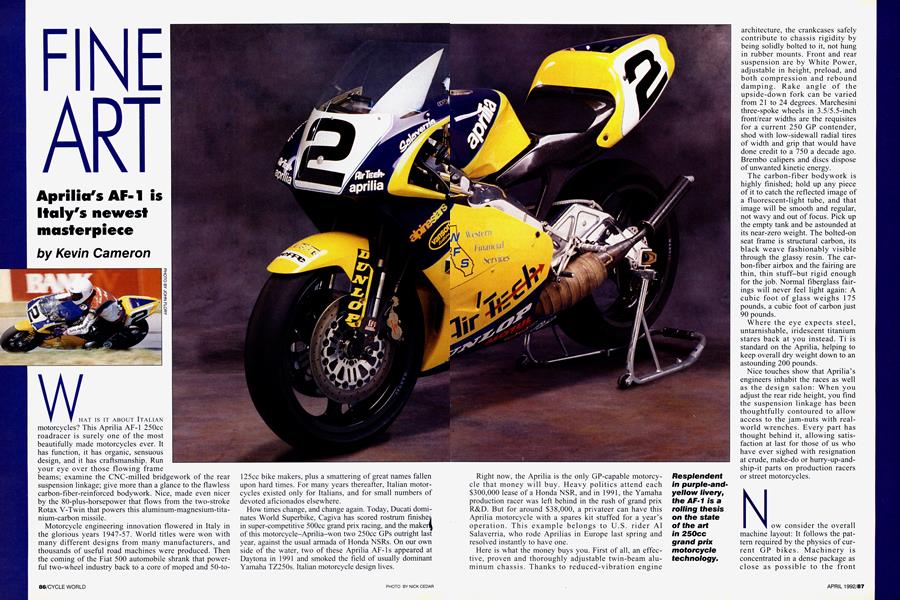

FINE ART

Aprilia's AF-1 is Italy's newest masterpiece

Kevin Cameron

WHAT IS IT ABOUT ITALIAN motorcycles? This Aprilia AF-l 250cc roadracer is surely one of the most beautifully made motorcycles ever. It has function, it has organic, sensuous design, and it has craftsmanship. Run your eye over those flowing frame beams; examine the CNC-milled bridgework of the rear suspension linkage; give more than a glance to the flawless carbon-fiber-reinforced bodywork. Nice, made even nicer by the 80-plus-horsepower that flows from the two-stroke Rotax V-Twin that powers this aluminum-magnesium-titanium-carbon missile.

Motorcycle engineering innovation flowered in Italy in the glorious years 1947-57. World titles were won with many different designs from many manufacturers, and thousands of useful road machines were produced. Then the coming of the Fiat 500 automobile shrank that powerful two-wheel industry back to a core of moped and 50-to-

125cc bike makers, plus a smattering of great names fallen upon hard times. For many years thereafter, Italian motorcycles existed only for Italians, and for small numbers of devoted aficionados elsewhere. How times change, and change again. Today, Ducati dominates World Superbike, Cagiva has scored rostrum finishes in super-competitive 500cc grand prix racing, and the maker| of this motorcycle-Aprilia-won two 250cc GPs outright last year, against the usual armada of Honda NSRs. On our own side of the water, two of these Aprilia AF-Is appeared at Daytona in 1991 and smoked the field of usually dominant Yamaha TZ250s. Italian motorcycle design lives. Right now, the Aprilia is the only GP-capable motorcycle that money will buy. Heavy politics attend each $300,000 lease of a Honda NSR, and in 1991, the Yamaha production racer was left behind in the rush of grand prix R&D. But for around $38,000, a privateer can have this Aprilia motorcycle with a spares kit stuffed for a year’s operation. This example belongs to U.S. rider AÍ Salaverria, who rode Aprilias in Europe last spring and resolved instantly to have one.

Here is what the money buys you. First of all, an effective, proven and thoroughly adjustable twin-beam aluminum chassis. Thanks to reduced-vibration engine architecture, the crankcases safely contribute to chassis rigidity by being solidly bolted to it, not hung in rubber mounts. Front and rear suspension are by White Power, adjustable in height, preload, and both compression and rebound damping. Rake angle of the upside-down fork can be varied from 21 to 24 degrees. Marchesini three-spoke wheels in 3.5/5.5-inch front/rear widths are the requisites for a current 250 GP contender, shod with low-sidewall radial tires of width and grip that would have done credit to a 750 a decade ago. Brembo calipers and discs dispose of unwanted kinetic energy.

The carbon-fiber bodywork is highly finished; hold up any piece of it to catch the reflected image of a fluorescent-light tube, and that image will be smooth and regular, not wavy and out of focus. Pick up the empty tank and be astounded at its near-zero weight. The bolted-on seat frame is structural carbon, its black weave fashionably visible through the glassy resin. The carbon-fiber airbox and the fairing are thin, thin stuff-but rigid enough for the job. Normal fiberglass fairings will never feel light again: A cubic foot of glass weighs 175 pounds, a cubic foot of carbon just 90 pounds.

Where the eye expects steel, untarnishable, iridescent titanium stares back at you instead. Ti is standard on the Aprilia, helping to keep overall dry weight down to an astounding 200 pounds.

Nice touches show that Aprilia’s engineers inhabit the races as well as the design salon: When you adjust the rear ride height, you find the suspension linkage has been thoughtfully contoured to allow access to the jam-nuts with realworld wrenches. Every part has thought behind it, allowing satisfaction at last for those of us who have ever sighed with resignation at crude, make-do or hurry-up-andship-it parts on production racers or street motorcycles.

1 ow consider the overall machine layout: It follows the pattern required by the physics of current GP bikes. Machinery is concentrated in a dense package as close as possible to the front wheel. The bike appears “solid.” You can’t see through the engine bay because it’s full of parts. It’s hard to see through the front wheel because the big discs fill most of the space in the 17-inch wheel, and because the large front fender spreads to protect the chromed surfaces of the fork from incoming stones, as well as smoothing air-entry to the radiator. Bridging the big space between powerplant and rear wheel is a long, long swingarm.

The Aprilia is the only GPcapable motorcycle that money will buy

Ten years ago, this layout would have failed; so much front-end weight bias would have let the rear tires of that era spin. Spanish chassis specialist Antonio Cobas, the man who created the twin-beam frame concept now universally used, says, “It is impossible to put too much weight on the front wheel.” Indeed, today’s riders expect to turn-in very decisively and to accelerate early and hard off corners; both of thesetechniques require maximum front-end weight bias. With weight so obviously far forward, and with their forks now só steeply set, race machines look as if they are braking hard when they are sitting still.

Slipped between the front wheel and engine is a wide, tall radiator. The amount of radiator surface required for cooling depends strongly on coolant temperature: The hotter the coolant, the greater the temperature difference between the surfaces of the radiator and the cooling air streaming past them.

When liquid cooling was first introduced on production roadracers almost 20 years ago, radiator surface area was half as great, and coolant temperature was held at 85 degrees C by a thermostat. But the best engines of that era made only 60 percent of the power of present 250s. Since then, it’« been found that as engine temperature is pulled down, power rises. Any heat transfer from hot engine to intake air expands that air, reducing its density-thus reducing power. If you cool the parts down, the lost power returns.

This Aprilia runs, even in Kansas summer heat, no warmer than 55 degrees C. Two quarts of water are circulated at 55 liters per minute (at 12,000 crank rpm) by a pump geared to the upper crankshaft.

A

/ mnd now the big engine question: Why, when all other GP engine producers have accepted the orthodoxy of large-area reed induction, does the Aprilia’s Austrian-made Type 258 Rotax engine have rotary-valve induction? Only 10 years ago, rotary valves were regarded as the ultimate two-stroke intake system, able to provide non-symmetrical timing and an unobstructed intake passage. Why did it leave the scene?

Rotary-valve induction was dropped from the 500cc class after 1983 because, although RV gives a strong, flat powerband, there is carburetion difficulty in getting up into that band from lower revs. Below the powerband, the engine barely carburâtes, but as it “climbs in,”.the torque rise is explosive.

On big-displacement bikes, that characteristic makes acceleration uncontrollable. Largearea reeds tamed that 500cc rush, and with development concentrating on them, it was natural to use reeds on new 250 designs, as well. But because a 250 has half the displacement of a 500, a sudden power onset is far less of a problem. The 250s need maximum power more than they need smooth power, whereas with 500s, the reverse is true.

The value of a rotary valve in 250s was also obscured by the rapid improvement in Yamaha and Honda reed engines, and by the lack of equally intensive development on rotary-valve designs. Now that Aprilia is seriously pursuing the matter, there are serious results. Despite this, Aprilia is said to be developing a reed-induction variant of the Rotax design for evaluation.

Rotary-valve induction is straightforward on the AF-1. The discs begin to open the intake port at about 135 degrees before top center, right where everyone else has always opened rotary valves (including the venerable Kawasaki AIR of 1967-69). Why not open it sooner? In some cases, more power can be had this way, even though the transfer and intake ports are open together for a time. The problem is carburetion. If the piston does not pull a vacuum on the case before the port opens, there is no “pop” of vacuum to make the carburetor deliver fuel. Opening too soon destroys the pop-and the carburetion-at low rpm. When open, the .025-inch-thick discs slice out of the ports, leaving them marvelously smooth and unobstructed, and return to be completely closed at 85 degrees ATDC.

Feeding the rotary intakes are 38mm Dell’Orto VHSB carburetors that are ingenious conversions of round-slide castings to flat-slide operation. The side-mounted carburetors constitute yet another reason for the twin-crank layout: Each cylinder needs its own intake disc. Early rotary-valve Twins had side-by-side cylinders firing at 180 degrees, with a carburetor projecting from each side of the machine. This made engines unacceptably wide, for even with the shortest possible carbs and intake tracts, there had to be adequate clearance from carb bellmouth to inner face of airbox-while still allowing sufficient cornering clearance. The V-Twin 258 Rotax engine is as narrow as it can be-and also light, at 62 pounds without pipes or carburetors.

is nothing remarkable in the basic design of the Type 258. It has its two counterrotating cranks in the same plane, stacked one above the other, so there is no side-to-side rocking couple as there is in the Honda NSR and Yamaha TZ250B, whose designs require cylinder centerlines to be offset laterally by some 65-70mm. (Yamaha cancels this couple with a balancer shaft; Honda does not.)

Balance in the Rotax V-design is easily achieved: With one cylinder sloping upward and the other down, and with both pistons coming simultaneously to TDC, the vertical components of their reciprocating imbalance cancel, leaving only a back-and-forth component. Likewise, the counterweights on the two

cranks cancel each others’ effects in the vertical plane, leaving only a “forth-and-back” component. It only remains to adjust the balance factor so reciprocating and counterweight imbalances exactly cancel. This can be done for any V-angle the designer chooses: If the V-angle is zero, the balance factor must be 100 percent; if 90 degrees, it is 70.7 percent, etc.

This exercise is intellectually satisfying, and practical besides: The resulting smoothness allows the engine to be bolted solidly to the frame without destroying it. Further, because the cranks counterrotate, they offer no net gyroscopic resistance to sudden flickover maneuvers of the bike.

Aprilio's engineers inhabit the races as well as the design studio

Rotcux Is an endless story

In this, the Aprilia is like the maneuverable Yamaha and Suzuki 500s, contrasted with the notoriously roll-sluggish single-crank Honda NSR500.

The Aprilia’s cranks are geared together on the left side, and they and the primary gears are lubed by llOcc of oil. The rotary-valve cases and discs are on the right. Behind the cranks, the case provides room for a compact, six-speed cassette gearbox, inserted from the right side. Whereas in most current GP engines the gearshafts, shift drum, shift rails and forks slide out as a unit, this Rotax design obliges the mechanic to perform feats of won-

drous dexterity, for the bottom fork and rail must be installed separately.

Also on the left side is the ignition generator/trigger unit, delivering charge and timing signals to a unique control box. Four separate ignition advance-retard curves are built into this box, and the tuner can select the one he desires by positioning screws in contact holes in the box.

A simple two-stroke roadracing engine coupled to a well-designed exhaust pipe still can suffer from a narrow powerband. To increase this, various schemes are used to shorten exhaust-port timing at lower rpm, thereby keeping the engine still in step with the pipe and widening the band. The Rotax uses a very simple system (titled with a corporate acronym of RAVE) consisting of an exhaustpressure-operated diaphragm that raises and lowers a gate in the exhaust port.

As an option, an electronically controlled exhaust-gate control is also available, similar to those used by the Japanese manufacturers. An electronic control can, for example, be programmed to take the hard edge off the torque curve for faster laps on a rainslicked track.

The cylinders on this production bike have three exhaust ports (a large central port plus two small sub-exhausts up high and flanking it) and five transfers of traditional layout. While Japanese designers experiment with extreme main-transfer backflow (in which the air-fuel flow from the transfer ports aims toward the very rear of the cylinder), and hook their secondary transfers around to flow slightly towards the exhaust, Rotax continues to use conventional 1970s-era transfers. The mains are moderately backflowed and the secondaries aim right at each other. Also in contrast to recent Yamaha and Suzuki GP engines, the Rotax retains domed pistons rather than the flat-tops used by the others.

I s it just fashion, or do these differences mean something? I suspect that the Rotax has advantages in airflow and powerband flatness from its rotary valves, making it possible to give competitive power and range without adopting Japanese transfer-port concepts. It may also be that the cylinders on the factorybacked Rotax racebikes are a step or two farther along the development trail compared to those on this production machine.

The cylinder heads are of the removableinsert type familiar in racing snowmobile circles. The water jackets are castings, but the combustion-chamber inserts are lathe-turned from bar. Squish clearance is normally 0.65mm (any closer and there is kissing at 13,500), and compression ratio is stated as 7.4:1, measured from exhaust closure rather than on the full stroke. Individual tuners have been known to use more compression.

As one well-known GP veteran notes, “Rotax is an endless story.” What he means is that, in effect, the engine’s design is part of the long craft tradition of European manufacturing, which relies on the availability of skilled technicians more than upon designfor-assembly and super-precise manufacture. Some examples? It is rare that a pair of new Rotax cranks will bring both pistons to TDC exactly together. Therefore, some capable person must take measurements and then make and fit offset crank keys to correct the phasing. Also, the ignition rotor mounts without a drive key onto a taper on the lower crank. This is European-traditional, but will it slip? One can only hope not. The rotary-valve discs are held to their hubs only by large nuts; will they slip? Usually not-if you make ’em real tight. For people raised on a diet of Japanese-manufactured raceware, features like these are a disagreeable surprise. Nevertheless, when adequate care is taken in assembly, the result is excellent performance.

What is to be said in sum? Here are superb cycle parts in a beautiful chassis, powered by a potent but labor-intensive engine. Mastering the idiosyncrasies takes time and may involve making mistakes, but proven potential is the dangling carrot that draws us onward.

So, is all this worth $38,000? Ah, what price glory?

Superb cycle parts in a beautiful chassis

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontUncle George's Last Ride

April 1992 By David Edwards -

Leanings

LeaningsThe Enchanted Vagabond

April 1992 By Peter Egan -

TDC

TDCRocket Fuel

April 1992 By Kevin Cameron -

Letters

LettersLetters

April 1992 -

Roundup

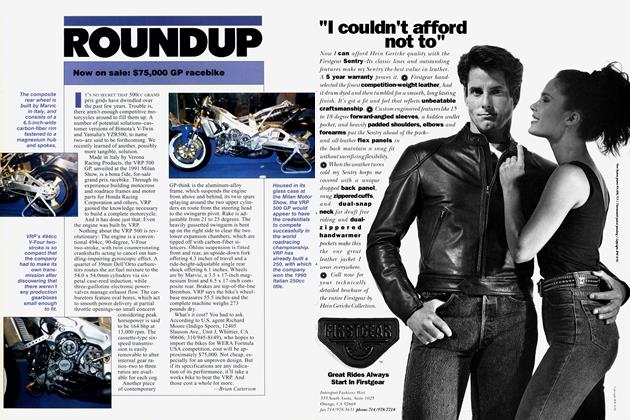

RoundupNow On Sale: $75,000 Gp Racebike

April 1992 By Brian Catterson -

Roundup

RoundupKtm Comes Back From the Brink

April 1992 By Alan Cathcart