More brakes, please

TDC

Kevin Cameron

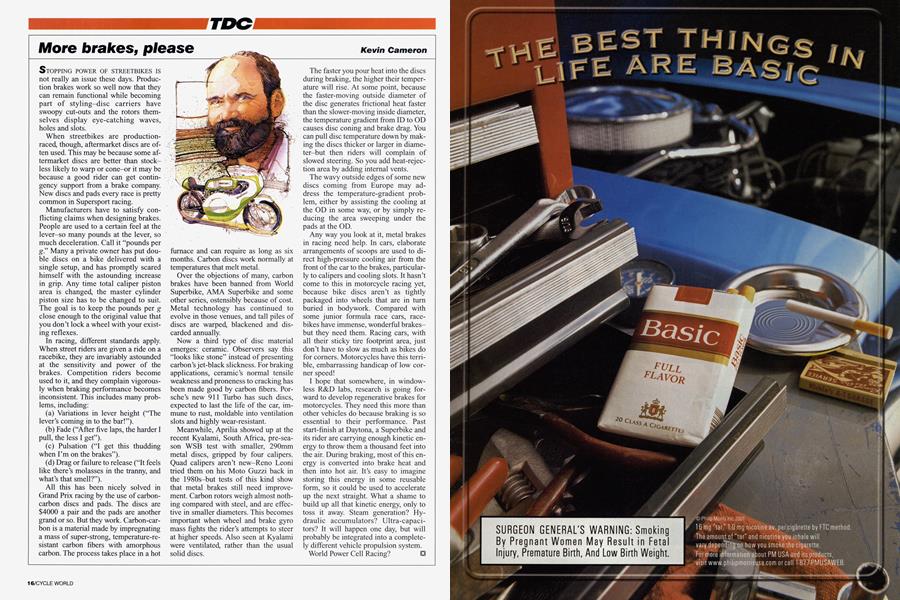

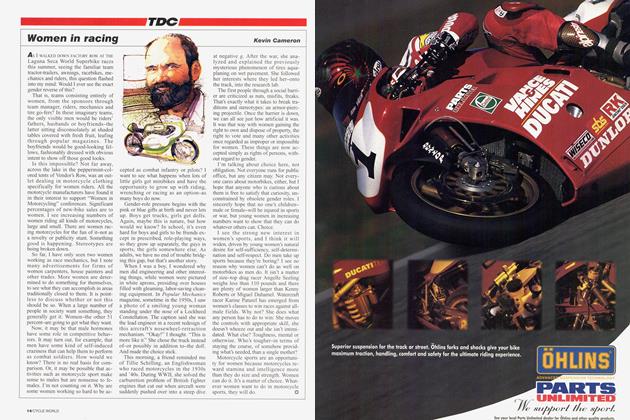

STOPPING POWER OF STREETBIKES IS not really an issue these days. Production brakes work so well now that they can remain functional while becoming part of styling-disc carriers have swoopy cut-outs and the rotors themselves display eye-catching waves, holes and slots.

When streetbikes are productionraced, though, aftermarket discs are often used. This may be because some aftermarket discs are better than stockless likely to warp or cone-or it may be because a good rider can get contingency support from a brake company. New discs and pads every race is pretty common in Supersport racing.

Manufacturers have to satisfy conflicting claims when designing brakes. People are used to a certain feel at the lever-so many pounds at the lever, so much deceleration. Call it “pounds per g.” Many a private owner has put double discs on a bike delivered with a single setup, and has promptly scared himself with the astounding increase in grip. Any time total caliper piston area is changed, the master cylinder piston size has to be changed to suit. The goal is to keep the pounds per g close enough to the original value that you don’t lock a wheel with your existing reflexes.

In racing, different standards apply. When street riders are given a ride on a racebike, they are invariably astounded at the sensitivity and power of the brakes. Competition riders become used to it, and they complain vigorously when braking performance becomes inconsistent. This includes many problems, including:

(a) Variations in lever height (“The lever’s coming in to the bar!”).

(b) Fade (“After five laps, the harder I pull, the less I get”).

(c) Pulsation (“I get this thudding when I’m on the brakes”).

(d) Drag or failure to release (“It feels like there’s molasses in the tranny, and what’s that smell?”).

All this has been nicely solved in Grand Prix racing by the use of carboncarbon discs and pads. The discs are $4000 a pair and the pads are another grand or so. But they work. Carbon-carbon is a material made by impregnating a mass of super-strong, temperature-resistant carbon fibers with amorphous carbon. The process takes place in a hot furnace and can require as long as six months. Carbon discs work normally at temperatures that melt metal.

Over the objections of many, carbon brakes have been banned from World Superbike, AMA Superbike and some other series, ostensibly because of cost. Metal technology has continued to evolve in those venues, and tall piles of discs are warped, blackened and discarded annually.

Now a third type of disc material emerges: ceramic. Observers say this “looks like stone” instead of presenting carbon’s jet-black slickness. For braking applications, ceramic’s normal tensile weakness and proneness to cracking has been made good by carbon fibers. Porsche’s new 911 Turbo has such discs, expected to last the life of the car, immune to rust, moldable into ventilation slots and highly wear-resistant.

Meanwhile, Aprilia showed up at the recent Kyalami, South Africa, pre-season WSB test with smaller, 290mm metal discs, gripped by four calipers. Quad calipers aren’t new-Reno Leoni tried them on his Moto Guzzi back in the 1980s-but tests of this kind show that metal brakes still need improvement. Carbon rotors weigh almost nothing compared with steel, and are effective in smaller diameters. This becomes important when wheel and brake gyro mass fights the rider’s attempts to steer at higher speeds. Also seen at Kyalami were ventilated, rather than the usual solid discs.

The faster you pour heat into the discs during braking, the higher their temperature will rise. At some point, because the faster-moving outside diameter of the disc generates frictional heat faster than the slower-moving inside diameter, the temperature gradient from ID to OD causes disc coning and brake drag. You can pull disc temperature down by making the discs thicker or larger in diameter-but then riders will complain of slowed steering. So you add heat-rejection area by adding internal vents.

The wavy outside edges of some new discs coming from Europe may address the temperature-gradient problem, either by assisting the cooling at the OD in some way, or by simply reducing the area sweeping under the pads at the OD.

Any way you look at it, metal brakes in racing need help. In cars, elaborate arrangements of scoops are used to direct high-pressure cooling air from the front of the car to the brakes, particularly to calipers and cooling slots. It hasn’t come to this in motorcycle racing yet, because bike discs aren’t as tightly packaged into wheels that are in turn buried in bodywork. Compared with some junior formula race cars, racebikes have immense, wonderful brakesbut they need them. Racing cars, with all their sticky tire footprint area, just don’t have to slow as much as bikes do for corners. Motorcycles have this terrible, embarrassing handicap of low corner speed!

I hope that somewhere, in windowless R&D labs, research is going forward to develop regenerative brakes for motorcycles. They need this more than other vehicles do because braking is so essential to their performance. Past start-finish at Daytona, a Superbike and its rider are carrying enough kinetic energy to throw them a thousand feet into the air. During braking, most of this energy is converted into brake heat and then into hot air. It’s easy to imagine storing this energy in some reusable form, so it could be used to accelerate up the next straight. What a shame to build up all that kinetic energy, only to toss it away. Steam generation? Hydraulic accumulators? Ultra-capacitors? It will happen one day, but will probably be integrated into a completely different vehicle propulsion system.

World Power Cell Racing?