Rossi’s woe

TDC

Kevin Cameron

ANYONE WITH METAL-CUTTING LATHE experience is familiar with tool chatter. Many causes are possible, but the end result is the same-a very rapid vibratory motion of the cutter bit, sometimes rapid enough to make a loud screech. Ideally, when the operator starts a fresh cut, the tool leaves behind it a smooth surface finish, peeling a shower of uniform chips. Then something changes subtly and chatter begins. Gone is the smooth finish, and in its place is an almost textile-like roughness-really a 3-D graph of the tool’s rapid vibratory motion. With a murmured expletive, the machinist stops the machine and looks for a cause.

A common one is a dull or improperly shaped tool. As the tool plows metal from the workpiece, that metal is being deformed so rapidly that it work-hardens. This local hardening resists the tool’s cutting action, pushing the tool point away. The elastic strength of the tool-holder now pushes the point back into the work, where for an instant it encounters softer metal and cutting resumes, only to have renewed work-hardening push the tool aside once more. This cycle repeats rapidly.

Another cause is inadequate tool rigidity. Often, a novice machinist will allow too much cutter bit to stick out of the toolholder, greatly increasing the flexibility of its support. By making sure that the tool and its holder are instead clamped with minimum overhang, rigidity is increased. Now, as metal hardens ahead of the cutter, there is adequately stiff tool support to keep it stably in the work. Chatter ceases and the tool leaves behind it a surface finish of textbook smoothness.

The point here is not to give the reader a short course in late 19th-century shop practice but to reveal something about how instability can lead to cyclic processes like vibration. In this case the dull tool hardens the material immediately ahead, which pushes a poorly supported tool aside in a cycle that can rapidly repeat.

Classic roadrace front tire chatter is a related phenomenon. As a bike rolls over into a turn, much of its weight is carried by the front tire. As cornering force is developed by the tire, its carcass is deformed laterally. If the rider has judged things rightly, the tread compound will be operating near the top of its friction-vs.-sliding velocity curve. Now there may be a disturbance-a bump, too-sudden throttle application or the like. This pushes the tire over the top of the curve into a region in

which further rise in sliding velocity causes grip to drop. With less grip, the deformation of the tire tread begins to snap back. As the tire regains its unstressed shape, local tire-sliding velocity drops and the tread re-grips. This reestablished grip now begins to deform the tire again. The cycle repeats.

Both of these chatter phenomena are driven by rapidly varying forces. In the case of the lathe, the hardness of the metal is not constant but increases the faster the tool tries to deform and push it aside. In the case of the tire, its grip is not directly proportional to sliding velocity but instead rises to a peak at some value, ceases to rise and then decreases.

Also, in both cases, flexibility is involved. On the lathe, as the material of the workpiece hardens ahead of the tool point, it pushes the tool out of the work by flexing the tool-holder. After the tool skips over the hardened material, it again bites into soft metal, allowing the cycle to repeat. On the motorcycle, the carcass of the tire is elastically flexible, and the front wheel is supported at the end of long, flexible fork legs. As the tread rubber loses grip from excess sliding velocity, tire and fork legs unload, allowing the tread to re-grip because their rapid return to their normal shapes almost zeroes out the sliding velocity, causing grip to once more increase.

Classic front tire chatter used to be an interaction between tire and fork leg flexibilities, but the adoption of the much stiffer male-slider or “upside-down” fork design moved the flex to other areas, such as the steering head and surrounding structure. Hydraulic suspension dampers are little use against chatter because they currently sign off above 17-22 cycles per second. More complication comes from the fact that lateral flexibility must now be intentionally designed into chassis parts to supplement suspension action at high lean angle. The more flexibilities there are, the more unintended interactions there can be with rapid tire grip/ release/grip cycling.

Recently, Valentino Rossi at the Jerez and Qatar GPs found that “vibration” limited the comer speeds of his Yamaha Ml. Why call it “vibra: tion” instead of just chatter? Its frequency has lately risen above the 20-22 cycles of classic chatter, to more like 25-27 cycles. I suspect that tire grip is now being increased by tire-makers fairly rapidly because the power of MotoGP engines has been so smoothed by various means that high comer speed has displaced the old “pointand-shoot” technique as the path to quicker lap times. As veteran rider Mick Grant said years ago, chatter is encouraged by conditions of heavy load and high grip. Rossi’s “vibration” may be just a growing pain of this continuing direction in tire technology.

As tire side-grip rises, tire and chassis deflections rise with it, increasing the amount of energy that is released any time a tire suddenly loses grip. And that in turn calls for more damping to prevent the resulting cyclic motion from settling into the steady “vibration” that sets a ceiling on comer speed. Where is this damping, this friction loss, to come from? Building it into the tire just increases operating temperature. And how would you damp vibrating fork legs or steering head? The motions involved are too small-of the order of a few millimetersfor control by normal hydraulic dampers. We know how metal ski-makers reacted when their early product chattered badly: They built wood into their laminates. Bells are made of metal because we want them to vibrate. Wood-with much more internal damping-hardly rings at all. Laminated plywood chassis, anyone?

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontBest of the Rest

July 2006 By David Edwards -

Leanings

LeaningsThe Fine Art of Riding Your Own Bike

July 2006 By Peter Egan -

Departments

DepartmentsHotshots

July 2006 -

Roundup

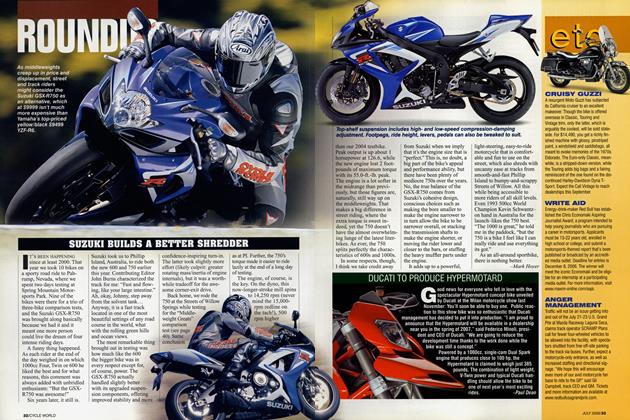

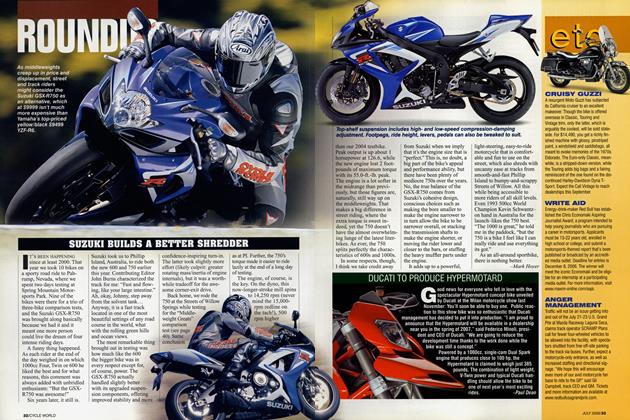

RoundupSuzuki Builds A Better Shredder

July 2006 By Mark Hoyer -

Roundup

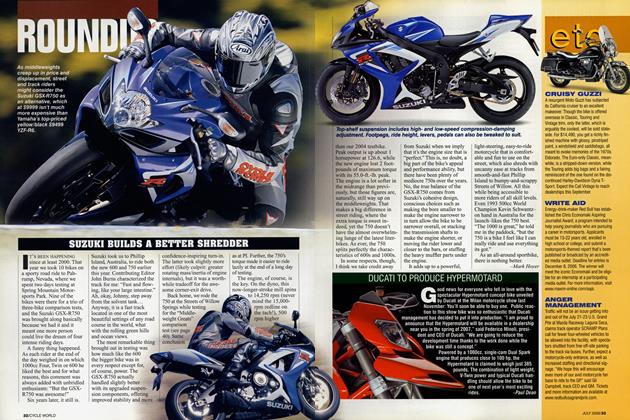

RoundupDucati To Produce Hypermotard

July 2006 By Paul Dean -

Roundup

RoundupEtc.

July 2006