Out of the weeds

TDC

Kevin Cameron

I’M READING ABOUT FRICTION AND LUbrication, because I’m interested in Rob Muzzy’s view that a “friction barrier” is keeping Superbike engines from making power at higher revs. This means 15,000 rpm and up-still small potatoes compared with F-l racing V-10 engines at their 17-18,000 rpm.

A couple of years ago, Muzzy noted that the Kawasaki inline-Four 750 would safely rev a full thousand rpm higher than its power peak, but with no power gain despite suitable-sized valves, ports and the rest of it. Whatever extra power was made by performing the engine cycle more times per minute was being cancelled by rapidly rising friction.

How and why does this happen? I want to know, and I also want to know if there’s a way around it.

Friction loss from shearing oil films can be figured out mathematically, just like lift on a wing. From that, engineers predict temperatures of oil and metal surfaces that ought to result from this oil shear. Calculated and actual results agree reasonably well-until high-rpm inertial forces make oil films critically thin. When that happens, oil and surface temperatures rise above the values calculated using the assumption of a full oil film. And when crankpin surface temperature rises above critical values (different for different materials, oils and oil additives), the bearing promptly seizes.

Does heat generation reach a runaway level, driving the viscosity of the

011 in the bearing’s loaded zone toward zero? Does seizure arise from simple metal-to-metal contact?

Plenty of bearings come out of race engines looking abused and overheated, but intact and running. This suggests heat, yes, but not runaway heat. It also suggests that something compensates in some way for the thinned oil film and the increased heat generated in the bearing. That something is at least partly the oil’s anti-wear additives, and/or its percentage of polar molecules.

In either case, substances in the oil bond to the crankpin and bearing surfaces, forming a tough but thin layer, rather like dense, sub-microscopic seaweed or swamp grass. When the oil film gets very thin, because the load is crowding the crankpin almost into contact with the rod’s bearing inserts, this is like water depth becoming too little

to float a boat. But the boat, thanks to all that wet swamp grass growing on the bottom, is protected from destroying itself against the harder stuff under the grass. Friction rises, but the boat can go right on sliding, protected by that clinging grass. The bearing scrubs along on that layer of absorbed chemistry, getting hotter-but not failing.

At some high temperature, however, that protective additive layer begins to de-sorb from those metal surfaces. That may be a critical event in bearing seizure.

All this assumes that the crankpin has been very highly finished during manufacturing, with a surface whose tallest “mountain” (the bearing people call it an “asperity”) does not cross that thin partial oil film. It assumes that the bearing and crankpin have been nicely broken-in to each other-a process that involves some contact and non-contact smearing and reshaping of the surfaces, making them even smoother.

But the neat thing about this highrpm bearing temperature rise is that it’s more than simple viscous oil shear would predict. Therefore, something extra is happening. That something else may be as simple as the extra friction from the bottom of the boat dragging in that protective grass.

There are other possibilities. Recent computer simulations have shown that when oil films become very thin under extreme local pressure, oil molecules no longer resemble a mass of boiling spaghetti-long, twisting molecules all writhing together. Instead, those long molecules line up parallel with each

other, rather as a pile of pencils will do if you rub your hand firmly back and forth across it. Once those molecules are oriented in this way, the only way they can get out from under that load is end-wise. And that’s not easy. That lack of ease means that the oil behaves as though its viscosity has greatly increased.

As engineers well know, more viscosity means higher bearing friction and higher horsepower loss. In our case of super-thin oil films in Superbike con-rods, running at very high revs, it may be that areas of the loaded zone are temporarily operating in this oriented-molecule, high-viscosity mode. The higher local viscosity would generate extra heat and extra friction-without leading to metal-to-metal contact that would destroy the bearing.

Why do oil films get so thin under load? The load squeezes oil out the sides of the bearing in the loaded zone, while viscosity sweeps more in from ahead. Under very heavy load, the outflow exceeds inflow, so the film becomes steadily thinner until piston acceleration ceases and the load reverses. Meanwhile, the oil system is busily refilling the unloaded side of the bearing clearance with oil, ready to carry the next big load as the piston undergoes deceleration. If enough oil is put in to keep the bearing afloat through the next load cycle, the boat won’t drag in the grass. But if there is any shortfall in the oil delivery, there may not be enough. In that case, the oil film will squeeze down prematurely. The boat does drag in the grass, or oil molecule orientation takes place-or whatever it is that actually happens. The result will be abnormally higher friction, more than predicted by oil film math. This could be a small part of Muzzy’s friction barrier.

Something similar may happen in valve gear, with all those hard, shiny cam lobes making intense line contact with tappets or rockers. Yamaha has published a paper showing a sharp increase in inline-Four piston friction above 12,000 rpm. Engineers suggest this may be caused by the piston’s thrust face deforming under inertial forces into a shape that discourages formation of a good, supporting oil film. That means pistons, too, down in the grass.

I suspect F-l engine designers know some neat stuff about how to keep their boats in deeper water, out of those high-friction weeds.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontMade In Minnesota

July 1997 By David Edwards -

Leanings

LeaningsSwords of Damocles

July 1997 By Peter Egan -

Letters

LettersLetters

July 1997 -

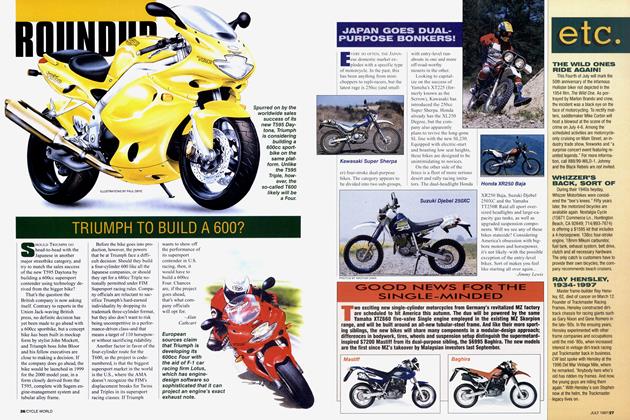

Roundup

RoundupTriumph To Build A 600?

July 1997 By Alan Cathcart -

Roundup

RoundupJapan Goes Dual-Purpose Bonkers!

July 1997 By Jimmy Lewis -

Roundup

RoundupGood News For the Single-Minded

July 1997