TDC

Oily Harry

Kevin Cameron

HARRY RICARDO, THE INTERNAL-COMbustion engine pioneer, built his own motorcycle at the turn of the century, when he still was quite a young man.

At the time, people argued about how lubricants worked. Some believed “oiliness”—the ability of oil molecules to attach themselves to metal surfaces—was crucial. The protective layer thus formed, they argued, was what prevented metal-to-metal contact, wear and failure.

More appealing to young Harry was the physical/mathematical view, which proposed that viscosity-the internal friction of the liquid as it passes over itself-was all you needed to know about a lubricant. As two surfaces slide over one another, this viscous friction is what keeps oil from being immediately and completely squirted out from between.

Ricardo resolved to investigate, using his own bike. Entering one of the economy runs then popular, he replaced the usual syrupy oil of that era with a much lighter oil. With some misgivings and only the alloted quart of fuel, he set out on the run. One by one, his rivals sputtered out, and he went the farthest by several miles. With less engine power wasted in overcoming lubricant viscosity, more was left to push the vehicle. This seemed to confirm the viscosity concept of oil lubrication.

Ricardo’s work predated the celebrated case of the marine thrustblock-the device that allows thrust from a rotating ship propeller to push the non-rotating ship. In its original design, collars were fixed to the shaft, bearing against corresponding collars fixed in the thrust block, all residing in an oil bath. And it worked well until steam turbines began to replace giant steam piston engines after 1910. That was when thrust blocks began overheating, boiling away their oil, and seizing.

An invention by A.G.M. Michell revealed the cause. As Ricardo had suspected, oil lubricates by forming a wedge that holds the moving parts away from one another. The motion sweeps oil in at the wide end of the wedge, and its viscosity prevents it all being squeezed out the sides before the last of it reaches the thin, trailing end of the oil wedge. The parts thus “surf” on the oil film, without touching each other at all. The pounding of steam piston engines wiggled the shaft in the thrust-block just enough to create oil wedges rotating with the shaft. But when the same shaft was driven by a much smoother steam turbine, there was no wiggle to create the oil wedges, and seizure soon followed.

Michell’s solution was to divide the non-rotating collars in the thrust block into angular segments, or thrust pads, each supported on a pivot. As the shaft turned, each pad tilted very slightly as an oil wedge formed under it. Fresh oil was swept in by viscosity at the wider, low-pressure edge of each wedge, and was then carried into the load-carrying, high-pressure region just as fast as the load squeezed it out everywhere else.

In the plain bearings that support most motorcycle crankshafts today, this oil wedge is formed by the crank journal’s orbiting slightly within the .002-inch clearance between it and the bearing shell, thereby creating a crescent-moon-shaped, tapered oil space that rotates with the crank. Combustion and inertia forces push the crank towards the inside face of the bearing shell, but the oil between them resists being squeezed out. It is being squeezed out all the time, of course, but is replaced just as quickly on the far side of the crank journal, where fresh oil easily enters the wide part of the crescent, ready to be swept into the thin, load-carrying region. Thus the oil film is maintained continuously. Engineers call this full-film support “hydrodynamic lubrication.”

All this makes it seem that oiliness is unnecessary-and so it is, if hydrodynamic lubrication can be maintained everywhere and at all times. But oil drains from stopped machinery, so start-up is largely unlubricated. And many mechanisms involve pressures or violent motions that momentarily damage the oil film. One such motion is in valvetrains, where very high sliding pressures exist between cam and tappet.

In the early days, it was indeed the very “oily” oils-such as castor-that were most successful at protecting parts not entirely lubricated by oil films. When oil films do break down, something has to protect the surfaces, which is where oiliness becomes important. If, when the oil film breaks down, there is still a monolayer of strongly adherent oil molecules on each surface-a condition termed “boundary lubrication”-it will offer at least some protection against failure.

Another boundary-lubrication problem exists between piston rings and cylinder wall near TDC, where the piston slows and stops under rising combustion pressure. Slowing down loaded moving parts that are sliding on an oil film is an invitation to film failure: With time on its hands, the oil squeezes out, leaving the rings sliding on a mostly dry cylinder wall. Accelerated wear in this region is the cause of the bell-mouthing of cylinders, and of the sharp edge that forms at the top of the ring travel.

Harry Ricardo was very curious about just what this region looked like as the piston descends. Would it indeed be dry and oil-free, as he suspected? Fortunate accident gave the answer: As he was dyno-testing a large, single-cylinder engine, it broke at the cylinder base flange, and the cylinder shot into the air and fell smash at his feet. Initially stunned, he then realized his opportunity and bent over to snatch up a hot piece of upper cylinder wall. To his delight, the uppermost part of the ring travel was dry and oil-free.

Once again, Harry Ricardo’s engineering intuition had proven ahead of its time.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontAn American Racer

September 1992 By David Edwards -

Leanings

LeaningsElectra-Glide

September 1992 By Peter Egan -

Letters

LettersLetters

September 1992 -

Roundup

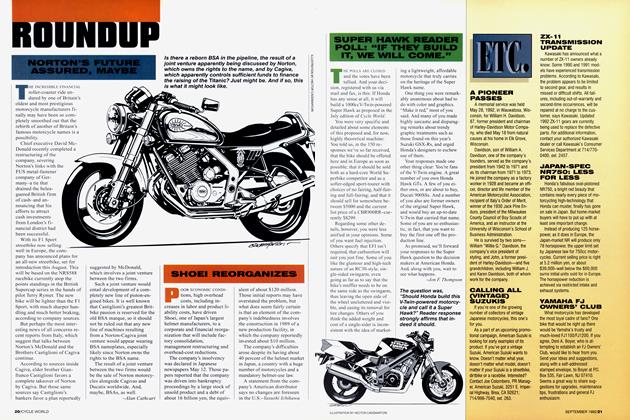

RoundupNorton's Future Assured, Maybe

September 1992 By Alan Cathcart -

Roundup

RoundupShoei Reorganizes

September 1992 By Yasushi Ichikawa -

Roundup

RoundupSuper Hawk Reader Poll: "If They Build It, We Will Come."

September 1992 By Jon F. Thompson