Air power

TDC

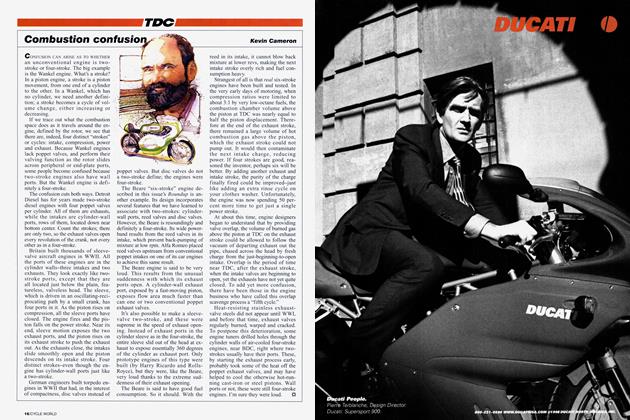

Kevin Cameron

WE ALL KNOW THE PISTON ENGINE can’t last forever. Although fabulously developed and refined-and a lot of fun-our gasoline-burners waste too much energy.

Alternatives? Demand for electrics will be soggy because, once the power finally reaches the road after coming through powerplants, miles of wire, transformers, battery cycles and what-have-you, it will cost more to drive a mile in an electric than in a gasolineburner. Fuel cells are attractive but still expensive. Many engineers favor hybrid systems: a small, high-efficiency sustainer engine charges some form of onboard energy storage, which in turn drives the vehicle. But for now, piston engines are the status quo, and it will take a big boot to knock them out.

The marketplace has no boot because nothing’s cheaper than gasoline piston power right now. California’s Air Resources Board (CARB) gave a kick with its “Zero Emissions Vehicle” initiative, but clumsily. The Federal people are bootless, mumbling defensively about not being in the business of picking winners. The smart new answer is to let the marketplace solve all our problems.

One day, some day, somehow, there will come shocking increases in fuel prices. That, friends, is the big boot. Wouldn’t it be nice to have an alternative power system for vehicles ready before the impact?

In about 1920, a forward-thinking Naval officer, Admiral Moffett, knew that the airplane would defeat the battleship, so Navy strength would soon depend on the aircraft carrier. He set about preparing everything that might be needed for a carrier force. One of those needs was for reliable, powerful engines for carrier aircraft. The liquidcooled engines then dominant were notoriously unreliable for flight over the sea, and the admiral wanted an alternative. He sent men from his new Bureau of Aeronautics (BuAero) to pester the engine manufacturers, all of which assured him that bigger, better liquid-cooled engines were the answer. Moffett knew what this meant: “We think our profit lies in making what we’re making.”

Officers Leighton and Wilson of BuAero knew that promising results were being obtained in certain places with air-cooled cylinders. One was at the tiny Lawrance operation, which had built three-cylinder trainer engines. The other was at the Army’s McCook Field, where an English engineer named Sam Heron was evolving a series of fast-improving air-cooled engine cylinders. Attempts to get a civilian manufacturer to build the Army’s design failed (though Heron’s cylinders went on to fly the Atlantic with Lindbergh, four years later). The admiral took a new approach, announcing that the Navy, dissatisfied with liquidcooled reliability, would buy no more such engines. The Navy would, however, buy 200 air-cooled radial engines that met a tough specification.

This applied a wedge to management at Wright Aero, a major builder of liquid-cooled engines. Under this pressure, a group of executives and engineers split away and, on the strength of the Navy’s offer to buy air-cooled radiais, was able to raise private money to create a new company. It was called Pratt & Whitney. In a daring, risky move, this new group simultaneously designed the Navy’s new engine, found a vacant plant, and began hiring and tooling for production.

With this shock development staring them in the face, Wright Aero, having absorbed Lawrance, suddenly found new success in its own aircooled developments.

The admiral’s boys had done well. Their opinion had been that, if an aircooled engine were given the same development that liquid-cooled types had already received, it would prove to be far more reliable, an ideal powerplant for carrier aircraft. Had they waited for the marketplace to bring this developed engine to them, they would have waited in vain.

Admiral Moffett interfered with the purity of the marketplace by offering to buy engines that didn’t exist, from people who didn’t want to make them. He was willing to take this risk because he trusted the judgment of his engine specialists at BuAero. The air-cooled radial turned out to be a good idea, just waiting for someone with the guts to fund it. Thanks to Admiral Moffett, there was a U.S. carrier force when the Pacific War began in 1941. And thanks to officers Leighton and Wilson, reliable and powerful air-cooled radial engines were also ready to power the aircraft that flew from those carriers. Hundreds of thousands of these engines were built, of up to 2000 horsepower, by both Wright and P&W. This engine type, that no one had wanted to build, went on to forge U.S. dominance in the amazing post-war growth of global aviation. Ironically, no liquid-cooled engine ever powered a major airliner!

CARB, by requiring auto-makers to offer a percentage of zero-emissions vehicles, has tried to be a present-day Admiral Moffett, to force a needed new technology into being. But it made a mistake in backing a political slogan (zero emissions) rather than a practical émissions-réduction technology. The air-cooled aircraft engine was, in 1923, ready to burst into flower at Admiral Moffett’s bidding, but cheap, long-lived batteries have not, thus far, popped into existence at the snap of CARB’s collective fingers.

Are there any 1990s Leightons or Wilsons out there, working quietly in some vehicles-procurement office, making realistic engineering assessments about the merits of competing future low-emissions powerplants? Is there a modern equivalent of Admiral Moffett to back them? Will the Post Office or some branch of the military offer to buy, at a stated price, 200 or 2000 or 20,000 vehicles that actually do a better job?

Nah. Planning is risky. Let the free market handle it. And wait until it costs $100 to fill the gas tank on your GSX-R.

View Full Issue

View Full Issue