Grace in hardware

TDC

Kevin Cameron

THERE IS GRACE IN THE BEST MECHANIcal design, but it is usually there not because of human aesthetic taste, but because nothing else will work.

In 1971, Kawasaki equipped its H1R road racers with the same cylinder studs as on the street H1. These were plain pieces of 8mm steel rod, cut to length, then roll-threaded on both ends. They were okay on the street, but they broke on the racer. The fractures were classical, occurring right where the thread root joined the full-diameter 8mm shank. A service bulletin arrived, noting the failures and promising improved studs before the next national-but we had lots of other races coming before that.

The studs were breaking because of what is called stress concentration. Think of tensile (pulling) stress in the studs as consisting of a bundle of fine fibers, running along the part, each fiber carrying part of the load. In the full-diameter shank, these imaginary fibers run parallel, spaced well apart from each other because they have room to spread out. But where they must neck down to the diameter of the first thread root, they crowd together at the surface of the stud. Think of stress concentration as the local density of fibers, and you can see why the studs broke where they did: Extreme concentration of stress at the sharp diameter reduction at the first thread.

The answer to this is non-intuitive, for it requires reducing the diameter of the stud’s shank, to be somewhat smaller than the root diameter of the thread. This small shank diameter must then smoothly flare outward to join the full thread diameter. The result is a graceful-looking part, more resembling the root and trunk of a tree than something from a machine. Why does it work? The small shank brings the lines of stress together in a smaller bundle, so they no longer have to neck down at the first thread and no longer concentrate stress there. The stress is now more nearly equal everywhere, so failures cease.

Knowing this, and having nothing else to hold my cylinders down the next weekend, I tried it. I put fresh, stock, snap-off-type studs in the lathe, chose a round-nosed tool, and cut the shanks down smaller than thread root diameter, with smooth flares to join the threads at either end. We never broke another stud. When improved studs arrived from Kawasaki, they looked remarkably like ours.

During WWII, Allison broke mainbearing cap studs in a similar fashion on its 1710-cubic-inch V-12 aircraft engines and the remedy was similar, with one difference. Allison engineers found that their studs were also subjected to bending, which further concentrated stress at just the point where the rigid full shank met the small diameter at the first thread. By reducing the shank diameter, they distributed this bending along the length of the shank, rather than focusing it at the first thread.

Suzuki faced this almost 10 years ago-combined tensile and bending stress-in its first race-kit con-rod bolts. Simply replacing a lower-specification steel with something fancier wasn’t the cure, though this sometimes works. For example, crankshafts, destroying themselves by vibratory torsional failure, have been “fixed” by use of a super material like ultra-clean vacuumremelted steel. They keep right on vibrating like crazy, but the new material survives it. But in almost every case, a more durable solution is to redesign the part to avoid the stress concentrations that turn into cracks. Suzuki’s early kit rod bolts were victims of transition from traditional to computerbased stress-analysis methods.

Twenty and more years ago, this kind of design work depended upon a combination of experienced designers and trial and error. Yet today, products must hit the market when they’re hot-not delayed by months of fatigue testing and expensive redesign.

To speed this process, engineers now use stress-analysis programs that break down complex part shapes into assemblies of simpler shapes called finite elements, to each of which it is possible to apply physical laws in straightforward fashion. A computer makes the zillion tedious calculations for all the elements under a given applied stress, making sure that conditions agree on both sides of all boundaries. Fancier programs, running on faster computers, do the same for moving parts as the stress in them varies continuously through their operating cycles. We have all seen the results-ghostly looking representations of machine parts, spider-webbed by lines defining the finite elements, and displayed in false colors that correspond to various levels of stress. A few minutes’ work with such a program can reveal unforeseen stress concentrations in parts-and can smooth the process of reliability testing considerably.

For all its apparent “intelligence,” this method is limited by its initial assumptions and by the way it’s applied, and must therefore be considered just another tool, not a substitute for good design work by an experienced engineer. There are countless examples of finite-element analysis misapplied, with laughable or tragic results-just as in another era, there were mistakes made when aircraft stress was estimated by sandbagging the wings until the spars buckled. Experience is now accumulating with finite-element analysis, and updated programs make procedural and other errors less likely, but even this won’t transform sophisticated mechanical design into a desktop activity, any more than spellcheck/grammarcheck will transform me into Shakespeare.

Back when actual human machinists turned the cranks on mills and lathes, parts designs were routinely simplified to save time. Today, with machines that as easily produce complex curves as they do straight lines, the suggestions of finite-element analysis are more easily translated into hardware. The result can be parts that even more closely resemble the invisible stresses that inhabit them. That is grace in hardware.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Last Indian

October 1994 By David Edwards -

Leanings

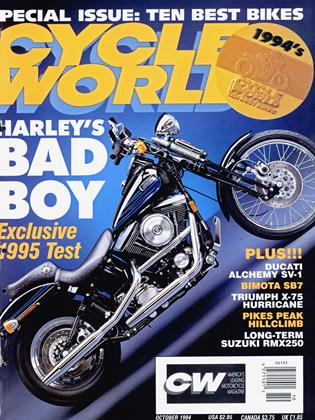

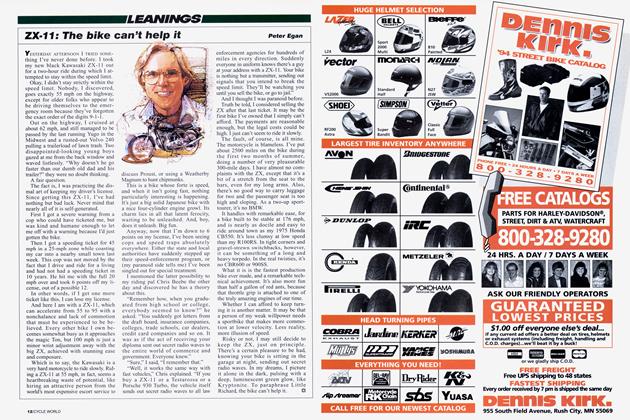

LeaningsZx-11: the Bike Can't Help It

October 1994 By Peter Egan -

Letters

LettersLetters

October 1994 -

Roundup

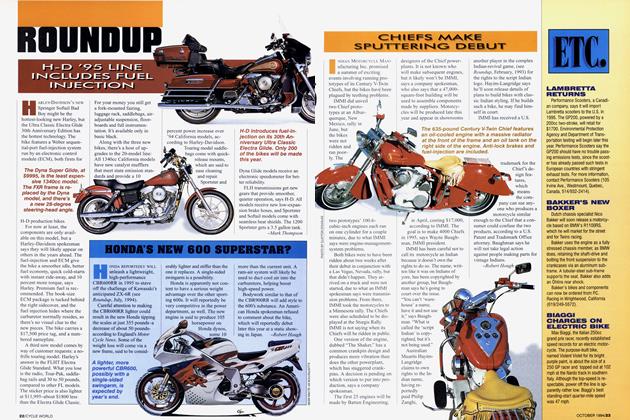

RoundupH-D `95 Line Includes Fuel Injection

October 1994 By Mark Thompson -

Roundup

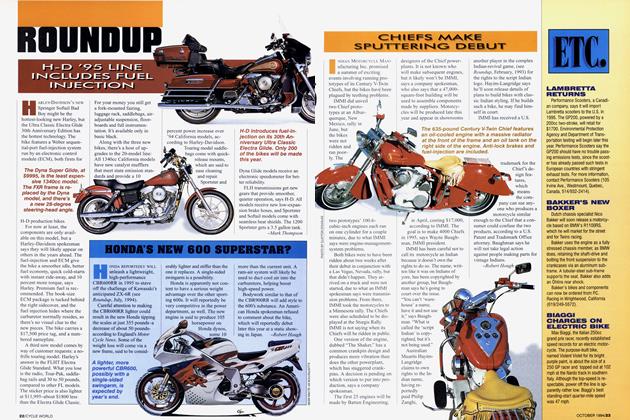

RoundupHonda's New 600 Superstar?

October 1994 By Robert Hough -

Roundup

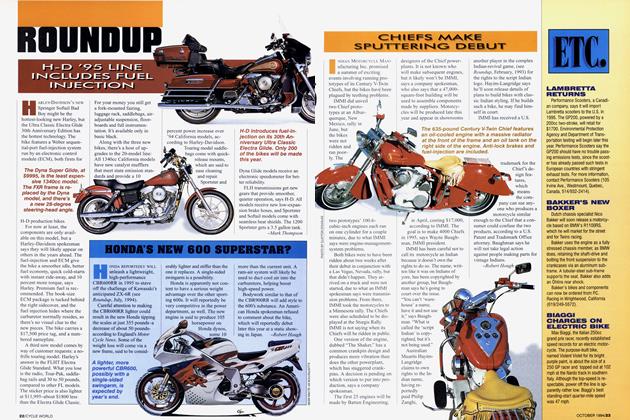

RoundupChiefs Make Sputtering Debut

October 1994 By Robert Hough