Boiling hot

TDC

Kevin Cameron

CAN YOU DAMAGE YOUR ENGINE BY

turning it off? This sounds like a trick

question, but what I mean is, are there

harmful things that can happen to an engine after it is shut down?

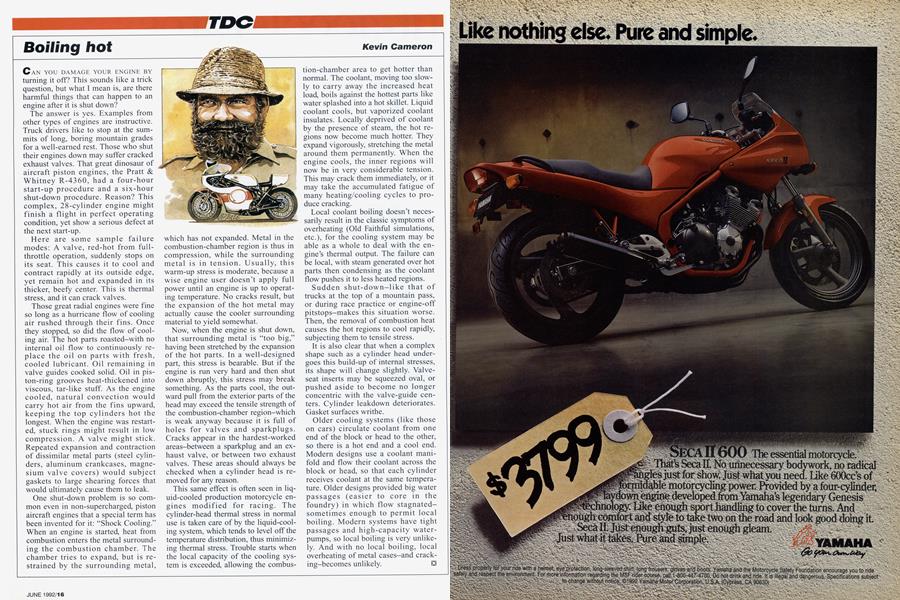

The answer is yes. Examples from other types of engines are instructive. Truck drivers like to stop at the summits of long, boring mountain grades for a well-earned rest. Those who shut their engines down may suffer cracked exhaust valves. That great dinosaur of aircraft piston engines, the Pratt & Whitney R-4360, had a four-hour start-up procedure and a six-hour shut-down procedure. Reason? This complex, 28-cylinder engine might finish a flight in perfect operating condition, yet show a serious defect at the next start-up.

Here are some sample failure modes: A valve, red-hot from fullthrottle operation, suddenly stops on its seat. This causes it to cool and contract rapidly at its outside edge, yet remain hot and expanded in its thicker, beefy center. This is thermal stress, and it can crack valves.

Those great radial engines were fine so long as a hurricane flow of cooling air rushed through their fins. Once they stopped, so did the flow of cooling air. The hot parts roasted-with no internal oil flow to continuously replace the oil on parts with fresh, cooled lubricant. Oil remaining in valve guides cooked solid. Oil in piston-ring grooves heat-thickened into viscous, tar-like stuff. As the engine cooled, natural convection would carry hot air from the fins upward, keeping the top cylinders hot the longest. When the engine was restarted, stuck rings might result in low compression. A valve might stick. Repeated expansion and contraction of dissimilar metal parts (steel cylinders, aluminum crankcases, magnesium valve covers) would subject gaskets to large shearing forces that would ultimately cause them to leak.

One shut-down problem is so common even in non-supercharged, piston aircraft engines that a special term has been invented for it: “Shock Cooling.” When an engine is started, heat from combustion enters the metal surrounding the combustion chamber. The chamber tries to expand, but is restrained by the surrounding metal, which has not expanded. Metal in the combustion-chamber region is thus in compression, while the surrounding metal is in tension. Usually, this warm-up stress is moderate, because a wise engine user doesn’t apply full power until an engine is up to operating temperature. No cracks result, but the expansion of the hot metal may actually cause the cooler surrounding material to yield somewhat.

Now, when the engine is shut down, that surrounding metal is “too big,” having been stretched by the expansion of the hot parts. In a well-designed part, this stress is bearable. But if the engine is run very hard and then shut down abruptly, this stress may break something. As the parts cool, the outward pull from the exterior parts of the head may exceed the tensile strength of the combustion-chamber region-which is weak anyway because it is full of holes for valves and sparkplugs. Cracks appear in the hardest-worked areas-between a sparkplug and an exhaust valve, or between two exhaust valves. These areas should always be checked when a cylinder head is removed for any reason.

This same effect is often seen in liquid-cooled production motorcycle engines modified for racing. The cylinder-head thermal stress in normal use is taken care of by the liquid-cooling system, which tends to level off the temperature distribution, thus minimizing thermal stress. Trouble starts when the local capacity of the cooling system is exceeded, allowing the combus-

tion-chamber area to get hotter than normal. The coolant, moving too slowly to carry away the increased heat load, boils against the hottest parts like water splashed into a hot skillet. Liquid coolant cools, but vaporized coolant insulates. Locally deprived of coolant by the presence of steam, the hot regions now become much hotter. They expand vigorously, stretching the metal around them permanently. When the engine cools, the inner regions will now be in very considerable tension. This may crack them immediately, or it may take the accumulated fatigue of many heating/cooling cycles to produce cracking.

Local coolant boiling doesn’t necessarily result in the classic symptoms of overheating (Old Faithful simulations, etc.), for the cooling system may be able as a whole to deal with the engine’s thermal output. The failure can be local, with steam generated over hot parts then condensing as the coolant flow pushes it to less heated regions.

Sudden shut-down-like that of trucks at the top of a mountain pass, or during race practice or engine-off pitstops-makes this situation worse. Then, the removal of combustion heat causes the hot regions to cool rapidly, subjecting them to tensile stress.

It is also clear that when a complex shape such as a cylinder head undergoes this build-up of internal stresses, its shape will change slightly. Valveseat inserts may be squeezed oval, or pushed aside to become no longer concentric with the valve-guide centers. Cylinder leakdown deteriorates. Gasket surfaces writhe.

Older cooling systems (like those on cars) circulate coolant from one end of the block or head to the other, so there is a hot end and a cool end. Modern designs use a coolant manifold and flow their coolant across the block or head, so that each cylinder receives coolant at the same temperature. Older designs provided big water passages (easier to core in the foundry) in which flow stagnatedsometimes enough to permit local boiling. Modern systems have tight passages and high-capacity waterpumps, so local boiling is very unlikely. And with no local boiling, local overheating of metal cases—and cracking-becomes unlikely.