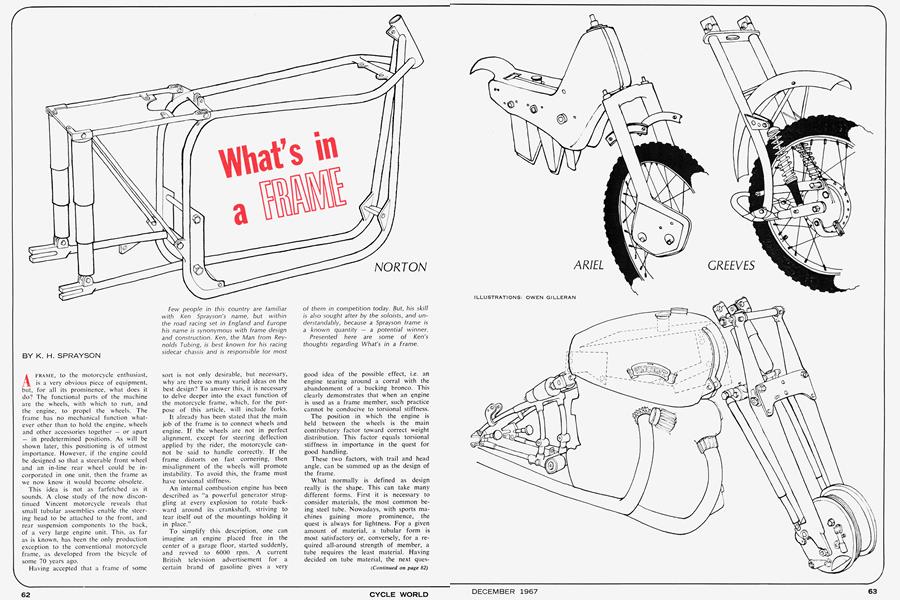

What's in a FRAME

K. H. SPRAYSON

A FRAME, to the motorcycle enthusiast, is a very obvious piece of equipment, but, for all its prominence, what does it do? The functional parts of the machine are the wheels, with which to run, and the engine, to propel the wheels. The frame has no mechanical function whatever other than to hold the engine, wheels and other accessories together — or apart — in predetermined positions. As will be shown later, this positioning is of utmost importance. However, if the engine could be designed so that a steerable front wheel and an in-line rear wheel could be incorporated in one unit, then the frame as we now know it would become obsolete.

This idea is not as farfetched as it sounds. A close study of the now discontinued Vincent motorcycle reveals that small tubular assemblies enable the steering head to be attached to the front, and rear suspension components to the back, of a very large engine unit. This, as far as is known, has been the only production exception to the conventional motorcycle frame, as developed from the bicycle of some 70 years ago.

Having accepted that a frame of some sort is not only desirable, but necessary, why are there so many varied ideas on the best design? To answer this, it is necessary to delve deeper into the exact function of the motorcycle frame, which, for the purpose of this article, will include forks.

It already has been stated that the main job of the frame is to connect wheels and engine. If the wheels are not in perfect alignment, except for steering deflection applied by the rider, the motorcycle cannot be said to handle correctly. If the frame distorts on fast cornering, then misalignment of the wheels will promote instability. To avoid this, the frame must have torsional stiffness.

An internal combustion engine has been described as "a powerful generator struggling at every explosion to rotate backward around its crankshaft, striving to tear itself out of the mountings holding it in place."

To simplify this description, one can imagine an engine placed free in the center of a garage floor, started suddenly, and revved to 6000 rpm. A current British television advertisement for a certain brand of gasoline gives a very good idea of the possible effect, i.e. an engine tearing around a corral with the abandonment of a bucking bronco. This clearly demonstrates that when an engine is used as a frame member, such practice cannot be conducive to torsional stiffness.

The position in which the engine is held between the wheels is the main contributory factor toward correct weight distribution. This factor equals torsional stiffness in importance in the quest for good handling.

These two factors, with trail and head angle, can be slimmed up as the design of the frame.

What normally is defined as design really is the shape. This can take many different forms. First it is necessary to consider materials, the most common being steel tube. Nowadays, with sports machines gaining more prominence, the quest is always for lightness. For a given amount of material, a tubular form is most satisfactory or, conversely, for a required all-around strength of member, a tube requires the least material. Having decided on tube material, the next question is, what size? The answer depends very much on the stresses involved in the various parts of the frame. Usually, the most highly stressed area is in the region of the front down tubes, and the least is in the sub-frame or seat tube. Within certain limits, the general rule is that a larger diameter thin gauge tube will provide a stronger member than a smaller thicker tube of like material content. The limiting factor is that if tube walls are too thin, necessary brackets and lugs tend to fracture around the weld fillet and tear completely out of the tube wall. All steel tube is of relative weight, but for competition work, a high tensile material such as Reynolds 531 is used because, for given loads, lighter gauges can be used than woud be necessary in mild steel.

(Continued on page 82)

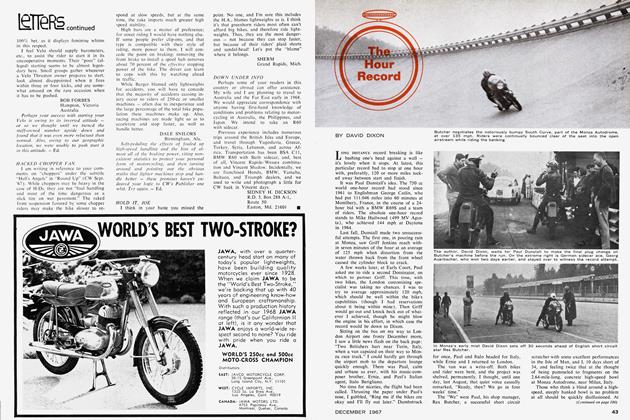

Few people in this country are familiar with Ken Sprayson's name, but within the road racing set in England and Europe his name is synonymous with frame design and construction. Ken, the Man from Reynolds Tubing, is best known for his racing sidecar chassis and is responsible for most of them in competition today. But, his skill is also sought after by the soloists, and understandably, because a Sprayson frame is a known quantity — a potential winner.

Presented here are some of Ken's thoughts regarding What's in a Frame.

Still, with a tubular frame in mind, the next thought is for lighter metals, such as aluminum alloy or titanium. Both have been tried, but with doubtful success. One reason is the elasticity modulus of the metals. This means the stiffness of the raw material, irrespective of tensile strength. Steel has an elasticity figure of 30, titanium is rated at 15 and aluminum alloy is rated at 10. Thus, for a given frame stiffness, titanium or alloy material content must be increased by 50 or 60 percent, respectively. This cancels out the weight saving advantages. Secondly, with both of these materials, there are welding problems.

Metallurgical^, welding presents no difficulty. Aluminum alloys can be satisfactorily welded with either oxyacetylene or argon arc processes. Though the basic materials can be heat treated to provide adequate strength, the weld areas will remain virtually untreated. With titanium, welding must be carried out very carefully to exclude all oxygen and hydrogen when heat is applied. This means that welding must be done in a closed cabinet which is exhausted and refilled with an inert gas, such as argon. Welding then is accomplished with an argon arc process, with base metal used as filler rod. The resultant fillet demonstrates a higher degree of stress raising and notch effect than normally is produced on corresponding steel frames joined with bronze welding. This lowers the fatigue resistance of the finished frame structure.

The next most popular method of frame construction is steel pressing. This is a cheaper method of construction which is employed when large quantities are to be produced. Pressings provide very satisfactory frames for general use. It is only in the exacting sphere of competition work, such as road racing and scrambling, that the adverse effects of steel pressing construction are found. Pressed frames usually are made in box form. This has great strength when loads are applied in a side or edge direction, but it has a weakness when the loads are across the corners or alternately torsional. A match box will demonstrate these characteristics.

Though pressings can be light, by the time adequate strength is built into them, little or no weight saving remains.

Castings and forgings also have been used in frame construction, but all with one or other of the drawbacks already discussed.

In regard to front forks, there has been a steady progression, over the years, from the unsprung bicycle fork to the modern hydraulically damped telescopic units. At various times during this period, various designers have used short and long links, leading and trailing links, hub center steering, and other weird and wonderful ideas. After the girder forks of the early years, with their external springs, the telescopic arrangement has, to date, proved most popular. The main virtues of these are a very neat appearance and the ability to be fabricated with a fairly easy machining process. Requirements of a front fork are similar to those of the frame. That is, the fork must deliver torsional stiffness without excess weight. Here the telescopic fork falls short. With the working clearance necessary in the telescopic action, working loads applied to the forks result in what can be termed as "sticktion" in the suspension medium. Torsional stiffness is limited to what can be obtained from clamping action of fork yokes and wheel spindle.

Link forks can almost be said to be a smaller version of the frame in which the front wheel is held by a fabricated structure. In this case, the suspension medium is independent of fork rigidity and usually is a proprietary unit such as is used on the rear of the machine. Short or long links, as with leading or trailing links, all have their pros and cons. However, the short leading link with a fully welded yoke assembly seems to offer the best all around advantages.

Hub center steering, as is used in automobiles, has very little to offer, as motorcycle steering requirements are very different from those of a car. With the necessary increase in the number of mechanical joints and their accumulative working clearances, fitted into the minimum space for neatness, wheel rigidity must suffer.

What is in a frame? Assuming that the best all-around results are obtained from a tubular structure, some designers and riders favor the duplex or "featherbed" arrangement, some the single loop, while others compromise with large diameter backbones with twin downtubes, and so on.

In my opinion, all this is irrelevant, providing the basic requirements are adequately met.

These basic requirements are correct design or layout, with rigidity or torsional stiffness, and avoidance of fatigue concentration in the more highly stressed areas — all this combined with lightness.

For racing, the frame must not be so light that it will not last for at least two seasons, yet it should be stout enough not to endanger the rider with sudden breakages. The enemy is fatigue.

The frame? The less there is of it, so much the better. ■