Swing Arm Lubrication

David Jonas

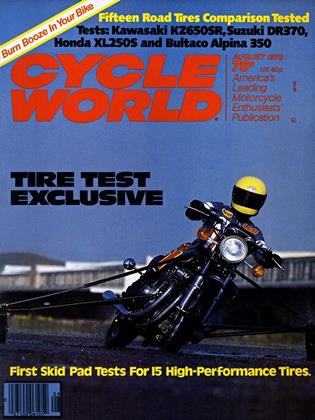

More swing arm movement, more bushing wear, more swing arm play, more endoes. Simple to understand and yet in these days of supersophisticated suspensions, the swing arm bushing continues to be overlooked, under-engineered and ill-maintained. Maybe this is because many modern off-road bikes are racing machines and the factories assume the bushings will be replaced frequently. The example shown is a Yamaha monoshock, because that’s the bike I own and used for this project, but the principles and tools described will work on any conventional motorcycle delivered with no grease fittings and with the factory’s only advice being a few words about greasing by hand. Lubricating bushings by hand, despite the advice, is ineffectual and timeconsuming. Unless the grease is packed under pressure, dirt and water will seep into the gaps and quickly perform a somewhat imprecise bore job on those hollow' cylinders. All is not lost. Through the use of inexpensive grease fittings, bushings can be properly lubricated in seconds with just a healthy squirt from a grease gun.

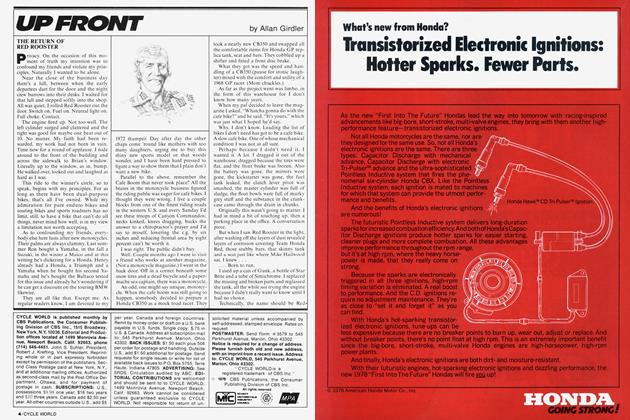

To do the job properly, you’ll need two grease nipples, a '/4-28 tap with T-handled chuck, a drill, a 7/32 or number 3 size drill bit, a smaller bit for pre-drilling, a punch, a crayon, some cutting oil and a tube of epoxy.

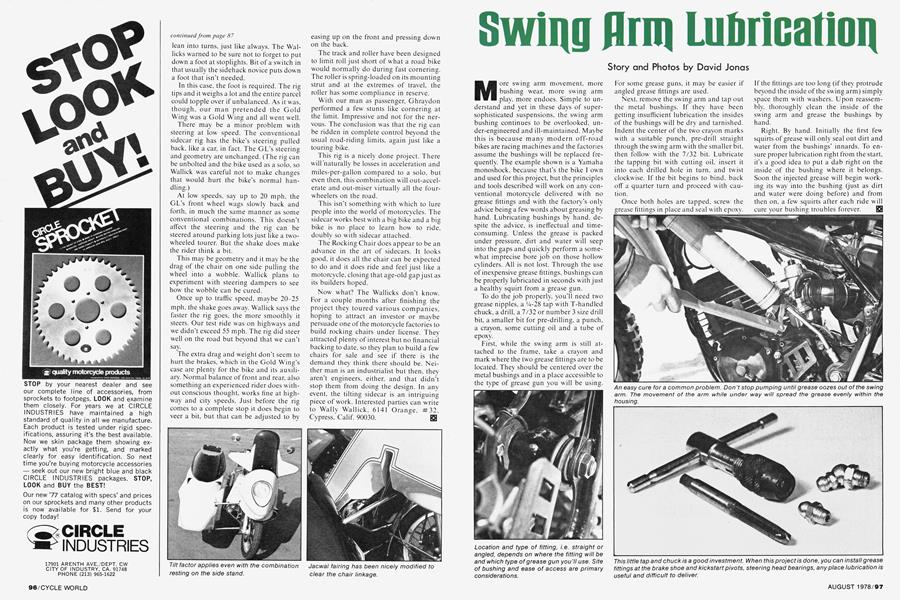

First, while the swing arm is still attached to the frame, take a crayon and mark where the two grease fittings are to be located. They should be centered over the metal bushings and in a place accessible to the type of grease gun you will be using.

For some grease guns, it may be easier if angled grease fittings are used.

Next, remove the swing arm and tap out the metal bushings. If they have been getting insufficient lubrication the insides of the bushings will be dry and tarnished. Indent the center of the two crayon marks with a suitable punch, pre-drill straight through the swing arm with the smaller bit, then follow' with the 7/32 bit. Lubricate the tapping bit with cutting oil, insert it into each drilled hole in turn, and twist clockwise. If the bit begins to bind, back off a quarter turn and proceed with caution.

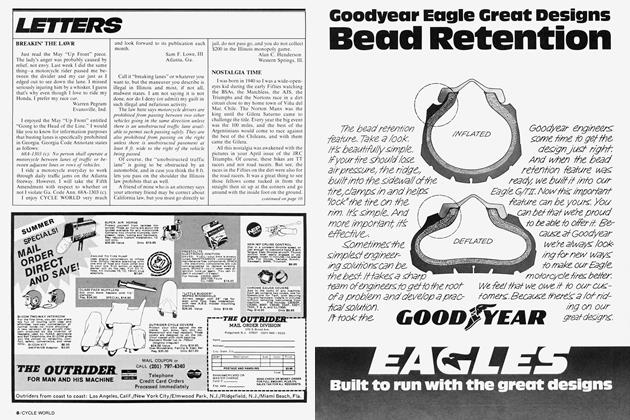

Once both holes are tapped, screw the grease fittings in place and seal wfith epoxy. If the fittings are too long (if they protrude beyond the inside of the swing arm) simply space them with washers. Upon reassembly. thoroughly clean the inside of the swfing arm and grease the bushings by hand.

Right. By hand. Initially the first few squirts of grease will only seal out dirt and water from the bushings’ innards. To ensure proper lubrication right from the start, it’s a good idea to put a dab right on the inside of the bushing where it belongs. Soon the injected grease will begin working its way into the bushing (just as dirt and water were doing before) and from then on, a few squirts after each ride will cure your bushing troubles forever. S