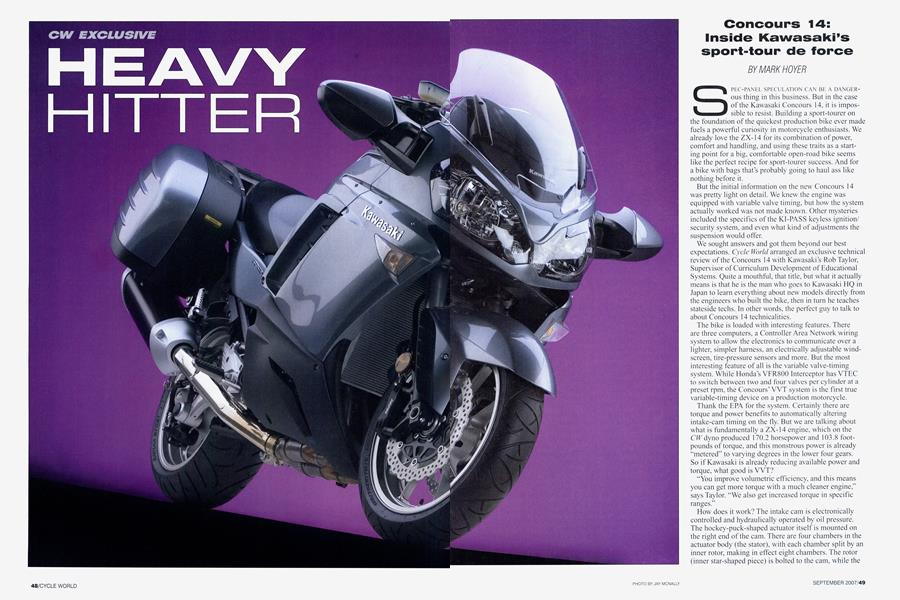

HEAVY HITTER

CW EXCLUSIVE

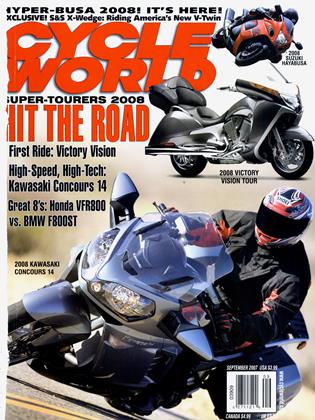

Concours 14: Inside Kawasaki's sport-tour de force

MARK HOYER

SPEC-PANEL SPECULATION CAN BE A DANGEROUS thing in this business. But in the case of the Kawasaki Concours 14, it is impossible to resist. Building a sport-tourer on

the foundation of the quickest production bike ever made fuels a powerful curiosity in motorcycle enthusiasts. We already love the ZX-14 for its combination of power, comfort and handling, and using these traits as a starting point for a big, comfortable open-road bike seems like the perfect recipe for sport-tourer success. And for a bike with bags that’s probably going to haul ass like nothing before it.

But the initial information on the new Concours 14 was pretty light on detail. We knew the engine was equipped with variable valve timing, but how the system actually worked was not made known. Other mysteries included the specifics of the Kl-PASS keyless ignition/ security system, and even what kind of adjustments the suspension would offer.

We sought answers and got them beyond our best expectations. Cycle World arranged an exclusive technical review of the Concours 14 with Kawasaki’s Rob Taylor, Supervisor of Curriculum Development of Educational Systems. Quite a mouthful, that title, but what it actually means is that he is the man who goes to Kawasaki HQ in Japan to learn everything about new models directly from the engineers who built the bike, then in turn he teaches stateside techs. In other words, the perfect guy to talk to about Concours 14 technicalities.

The bike is loaded with interesting features. There are three computers, a Controller Area Network wiring system to allow the electronics to communicate over a lighter, simpler harness, an electrically adjustable windscreen, tire-pressure sensors and more. But the most interesting feature of all is the variable valve-timing system. While Honda’s VFR800 Interceptor has VTEC to switch between two and four valves per cylinder at a preset rpm, the Concours’ VVT system is the first true variable-timing device on a production motorcycle.

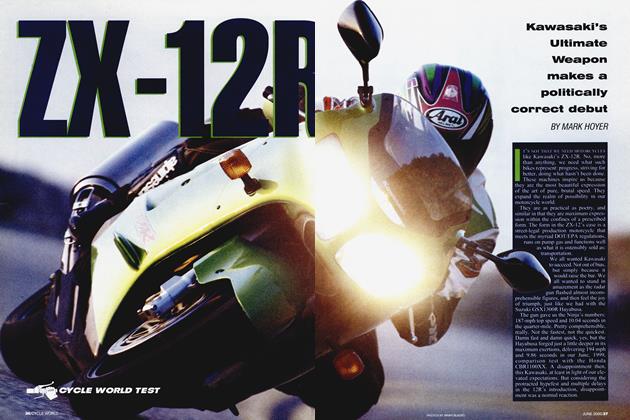

Thank the EPA for the system. Certainly there are torque and power benefits to automatically altering intake-cam timing on the fly. But we are talking about what is fundamentally a ZX-14 engine, which on the CWdyno produced 170.2 horsepower and 103.8 footpounds of torque, and this monstrous power is already “metered” to varying degrees in the lower four gears.

So if Kawasaki is already reducing available power and torque, what good is VVT?

“You improve volumetric efficiency, and this means you can get more torque with a much cleaner engine,” says Taylor. “We also get increased torque in specific ranges.”

How does it work? The intake cam is electronically controlled and hydraulically operated by oil pressure.

The hockey-puck-shaped actuator itself is mounted on the right end of the cam. There are four chambers in the actuator body (the stator), with each chamber split by an inner rotor, making in effect eight chambers. The rotor (inner star-shaped piece) is bolted to the cam, while the stator (outside piece) carries the cam sprocket and chain. Oil is fed through the cam into the advance or retard passages. As one side gets filled, the other bleeds off and drains back to the sump through the cam-chain tunnel.

An external line from the front of the engine supplies the oil-control valve, which is mounted to the side of the cylinder head. For simplicity, this oil pressure is provided by the standard engine oil pump. This means less weight, fewer moving parts, less “oil wear.” Every time oil is run through gears or a pump it is “munched,” which increases temperature and essentially wears it out faster.

“Using components already in place and tapping their full potential is what it’s all about,” says Taylor.

Throttle position, ground speed, transmission speed (i.e. which gear) all affect how the ECU manipulates the solenoid-actuated directional valve that controls the oil flow into the actuator.

“The solenoid is almost like a stepper motor, in that the stroke is controlled,” says Taylor. “The system is very accurate, and the ECU can control orifice openings to an essentially infinite degree between fully open and fully closed. It also has a quick reaction time.”

Oil pressure and volume to operate the VVT system are much lower than that required to lubricate the engine. This means that normal engine use and wear or the oil filter getting plugged up as it ages has no effect on cam timing.

For easy starting and proper emissions, a locking pin sets the cam in the “starting” position and, according to the technical manual, locks the cam for idle. Off idle, the pin is released and VVT is allowed to operate.

Cam timing variance is an astonishing 23.8 degrees. This is more than two teeth-a huge change. Most of the manipulation of cam timing occurs in the midrange, but there is also more advance (and therefore more overlap) at high rpm. Although Kawasaki didn’t release the spec, it is conceivable that at low rpm, overlap with the exhaust valves can be eliminated, maximizing cylinder filling and ensuring zero extra hydrocarbons sneak out the exhaust. Result? Bottom end like a cruiser, top end like a sportbike.

Interestingly, the system is not electronically linked to the fuel-injection system. The EFI and VVT systems simply run in parallel. The EFI doesn’t need to know where the cam is because it already measures the engine’s air/fuel needs via the usual sensors for engine and ambient temperature, intake manifold air pressure and so forth. VVT control is undertaken in a different section of the ECU using a separate map. Crankshaft, cam and throttle-position sensors are used to feed information to the system.

“It is very, very precise,” says Taylor. “It has to be: 1 or 2 degrees of cam-timing error can cause havoc.”

Other benefits of the system?

“The VVT actually makes the bike overall less mechanically complicated,” says Taylor. “The exhaust system can be smaller; there is no exhaust butterfly on this model because it is not needed. Using VVT, we control cylinder filling and can adjust exhaust output and emissions, thus the minimal catalyzers and no oxygen sensors required on the U.S. model.”

The fuel-injection system is similar to that of the ZX14, with dual throttle valves for each cylinder, one controlled by the rider’s right wrist, the other by the computer. Underneath all this intake trickery is fundamentally the same 1352cc inline-Four that so ably propels the ZX-14. Dual gear-driven balance shafts essentially eliminate secondary vibration. Compression is lowered from 12.0 to 10.7:1.

Throttle body diameters are reduced 4mm (to 40mm) to increase intake velocity at lower rpm for improved midrange power. The fuel injectors are upgraded to 12-orifice units, each of the tiny holes 75 microns or .003-inch across. The ZX14 used 10-hole injectors. “The new injectors give you a better burn, which means the less you have to worry about down the pipe to make it clean on the back side,’' Taylor points out. Nonetheless, the 4-2-1 exhaust system has two small catalyzers, one in the pipe and one in the silencer.

Claimed torque is 102.5 foot-pounds at 6200 rpm. This is a torque peak roughly 1600 rpm lower than that of the big Ninja. No horsepower figure was released, but expect it to be lower than the ZX-14’s because the overall engine tune is more mellow to suit this bike’s intended use. Based on the claimed torque, we’d guess mid-140-horsepower at the rear wheel. Plenty stout.

To accommodate the shaft drive bevel gear, the crankcases are new, but not much else is different. As the challenges of meeting noise emissions get ever more difficult, Kawasaki, like other manufacturers, works very hard to reduce unwanted decibel sources so that the things we like to hear-exhaust note, for example-can have some tone and volume. Therefore, the thin-wall casting of the engine cases is optimized for rigidity and lack of resonance. Added benefit of the rigidity is increased bearing-and therefore enginelife because of improved stability and alignment of moving parts.

The six-speed transmission features a new clutch. A set of springs works as a damping mechanism, and the back-torque-limiting system also has been altered to suit the added backlash and chatter inherent to a shaft-drive system. So there are two sets of springs, the normal ones for the clutch, and another set to control and damp the deceleration action. The five-position lever works on a radial hydraulic master cylinder.

The over-engine aluminum monocoque frame is similar to the ZX-14’s but 4 pounds lighter. The powerplant is solidly mounted for greater torsional rigidity of the overall package, with mass moved very far forward to ensure good front-end feel and accurate steering response. Wheelbase grows from 57.5 inches on the ZX-14 to 59.8 on the Concours. Rake and trail are substantially different with 23 degrees and 3.7 inches morphing into 26.1 degrees and 4.4 inches. Claimed dry weight for the standard version is 606 pounds, with the ABS model 9 pounds heavier. For comparison, the Yamaha FJR1300’s claimed dry weight is 582 pounds and the BMW K1200GT’s is 550.

A 43mm inverted fork features rebound damping and spring-preload adjustment. Nothing really fancy going on up there, even if the brakes feature Kawasaki’s now-trademark petal-style discs and four-piston, four-pad calipers. The Tetra-Lever rear suspension is where the new action is.

“The system helps control up and down motion typical to shaft drive,” says Taylor. “It’s a very rigid heavy-duty onepiece swingarm design.”

All the torque available from the engine could easily cause the pinion gear to try to “climb” up the ring gear in the rear wheel on acceleration, leading to the classic chassis jacking effect. The four-bar linkage used here, like on BMW’s Paralever, directs the torque back to the chassis, so that throttle position has no effect on rear-suspension attitude.

The bottom-link Uni-Trak suspension features a shock with remote hydraulic preload adjustment, plus a stepless rebound-damping screw. Travel is 5.4 inches. The stout castings of the rear suspension and final drive are quite stylized and on the left side are in plain sight because of the use of the single, right-side muffler.

“One silencer weighs less, but it was also a styling decision,” admits Taylor. “We didn’t want to hide the TetraLever.”

When we moved on to the electrical system and started talking about the proximity-sensor activation and the large LCD display, the true complexity of the Concours 14 was revealed.

Three ECUs ride along with you. The socalled Smart ECU handles main security, while a Steering Lock ECU is a sub-ECU to the Smart ECU. Then there is the EFI ECU. Got it? It gets better!

To allow all the data transmission and communication among the computers, this bike uses a full CAN wiring system like that of high-end automobiles. This is necessary for KI-PASS, or the Kawasaki Intelligent Proximity Activation Start System, to work.

At the core of KI-PASS is the Mitsubishi Misty 1 transponder encoding system, just like that used for automobile keyless systems. The “key” fob you carry has a transponder. The ignition switch on the bike has a key that can only be removed or turned when the transponder is within its 5.25-foot range. To start the bike, you push the key in. A signal is then sent to the Smart ECU that says someone is trying to turn on the bike, so the Smart ECU sends a tickler signal to the fob, which incites the fob to send its own unique code back to the Smart ECU that says, “Yes, this is the right fob.” Then the Smart ECU sends a signal to the key-switch ECU, which then communicates the command back to the Smart ECU. At this point, given the right fob, “correlation” occurs-all the transmitted signals have been recognized and accepted-and then the smart ECU turns on the Engine ECU and the rest of the bike. The process takes less than 1 second. At this point, the rider can push the start button as normal.

There are two options when it comes to unlocking the bags, fuel cap or seat: The fob has an integral standard key that is revealed at the push of a button; alternatively, the main ignition key that normally remains in place in the tripleclamp switch can be removed when the fob is in range and the switch is moved to the FSS (fuel, seat, storage) position. When the fob is out of range, the key can’t be turned and the computer electromechanically locks the steering head. If the fob battery is low, the LCD dash displays a warning.

What happens if you drop the fob when riding? No, the bike doesn't die, but rather the Mileage Locator initiates and the dash will display the distance from the point when fob went out of range. Hopefully you can backtrack and find it, and hopefully you find it in one piece!

To discourage theft and parting-out of the bike, the Smart ECU stores the last known (ever-changing) ID codes for the fob, EFI ECU, Steering Lock ECU and even tire-pressure sensors. The dealer-only Kawasaki Diagnostic System is required to reprogram an ECU to accept new electronic components. Therefore, you can’t change the components in the case of theft because they won’t communicate.

The bottom line is, if you are the owner, you just place the fob in your pocket, walk up, turn the bike on, push the starter button and go.

The EFI ECU communicates via CAN with the dash to display rpm, water temp, gear position, fuel level and range, etc., while the tire-pressure monitoring system transmits FM signals from the valve-mounted wheel sensors to the KIPASS ECU.

“The FM frequency is specific to each transponder,”

Taylor says. “The wheel sensor infinitely changes the signal while communicating with the ECU, so two bikes side by side would cause no interference, and the front and rear sensors operate on different frequencies.”

There is a warning only when pressure is low; it won’t warn against overinflation. Both Taylor and the technical manual state that this is a safety system, not a replacement for the owner’s own tire-pressure gauge. Battery life is a minimum of five years on the transmitters, and a low-battery warning will appear on the dash display.

All this makes the electrically adjustable windscreen and its 4.5 inch range seem pretty straightforward. There is a left-bar-mounted switch that activates an electric motor in the fairing. Kawasaki did spend time in its wind tunnel to be sure that the screen in its fully raised position didn’t increase front-end load at speed because that would make the steering heavy. The screen stays in the position you leave it when you shut down the bike, unlike, say, the Yamaha FJR’s that retracts to its lowest setting automatically.

While the Concours 14 looks large and imposing in photos, its actual physical presence is quite compact. The riding position, at least when we tried it out in our photo studio, is comfortable but sporting. (We weren’t able to ride the preproduction bike because Kawasaki would only allow its own employees to do so.)

Kawasaki’s press material for the Concours 14 contains phrases such as “incredible level of sporting performance” and a “supersport core.” It is hard to argue based on what we have learned. Final spec-panel speculation? Saddlebags will never have traveled through the quarter-mile so fast. □

For additional photography of the Concours 14, log on to www.cycleworld.com

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontAnatomy of A Black Eye

September 2007 By David Edwards -

Leanings

LeaningsA Trip To the New Barber

September 2007 By Peter Egan -

TDC

TDCTechnology Duel

September 2007 By Kevin Cameron -

Departments

DepartmentsHotshots

September 2007 -

Roundup

RoundupSmaller, Lighter, Faster

September 2007 By Kevin Cameron -

Roundup

Roundup2008 Street Trip

September 2007 By Blake Conner