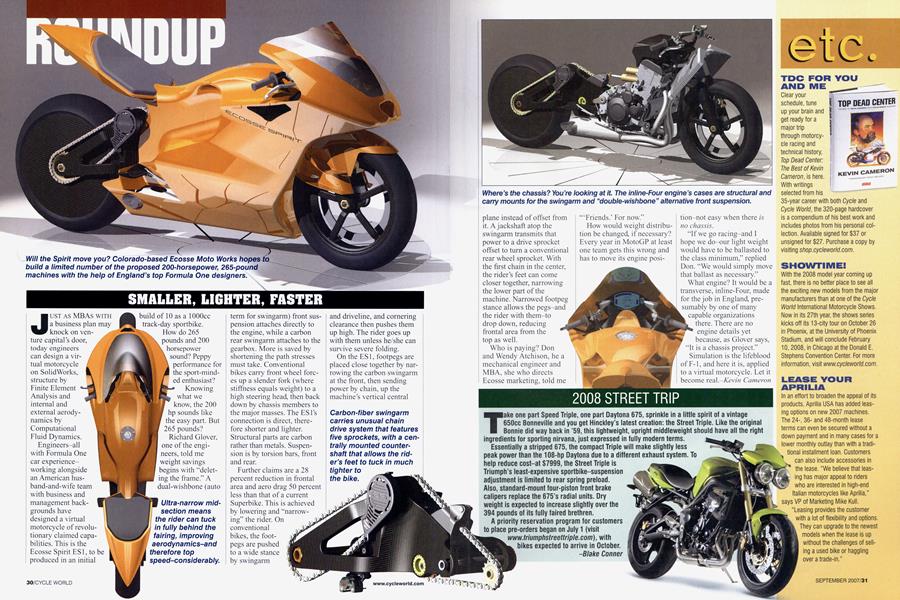

SMALLER, LIGHTER, FASTER

ROUNUP

JUST AS MBAS WITH a business plan may knock on ven-

ture capital's door, today engineers can design a virtual motorcycle on Solid Works, structure by Finite Element Analysis and internal and external aerodynamics by Computational Fluid Dynamics. Engineers-all with Formula One car experienceworking alongside an American husband-and-wife team with business and management backgrounds have designed a virtual motorcycle of revolutionary claimed capabilities. This is the Ecosse Spirit ESI, to be produced in an initial build of 10 as a lOOOcc track-day sportbike.

How do 265 pounds and 200 horsepower sound? Peppy performance for the sport-minded enthusiast? Knowing what we know, the 200 hp sounds like the easy part. But 265 pounds?

Richard Glover, one of the engineers, told me weight savings begins with “deleting the frame.” A dual-wishbone (auto term for swingarm) front suspension attaches directly to the engine, while a carbon rear swingarm attaches to the gearbox. More is saved by shortening the path stresses must take. Conventional bikes carry front wheel forces up a slender fork (where stiffness equals weight) to a high steering head, then back down by chassis members to the major masses. The ESl’s connection is direct, therefore shorter and lighter. Structural parts are carbon rather than metals. Suspension is by torsion bars, front and rear.

Further claims are a 28 percent reduction in frontal area and aero drag 50 percent less than that of a current Superbike. This is achieved by lowering and “narrowing” the rider. On conventional bikes, the footpegs are pushed to a wide stance by swingarm and driveline, and cornering clearance then pushes them up high. The rider goes up with them unless he/she can survive severe folding.

On the ES 1, footpegs are placed close together by narrowing the carbon swingarm at the front, then sending power by chain, up the machine’s vertical central

plane instead of offset from it. A jackshaft atop the swingarm transmits that power to a drive sprocket offset to turn a conventional rear wheel sprocket. With the first chain in the center, the rider’s feet can come closer together, narrowing the lower part of the machine. Narrowed footpeg stance allows the pegs-and the rider with them-to drop down, reducing frontal area from the top as well.

Who is paying? Don and Wendy Atchison, he a mechanical engineer and MBA, she who directs Ecosse marketing, told me “‘Friends.’ For now.”

How would weight distribution be changed, if necessary? Every year in MotoGP at least one team gets this wrong and has to move its engine position-not easy when there is no chassis.

“If we go racing-and I hope we do-our light weight would have to be ballasted to the class minimum,” replied Don. “We would simply move that ballast as necessary.” What engine? It would be a transverse, inline-Four, made for the job in England, presumably by one of many capable organizations there. There are no engine details yet because, as Glover says, “It is a chassis project.” Simulation is the lifeblood of F-l, and here it is, applied to a virtual motorcycle. Let it become real Kevin Cameron

View Full Issue

View Full Issue