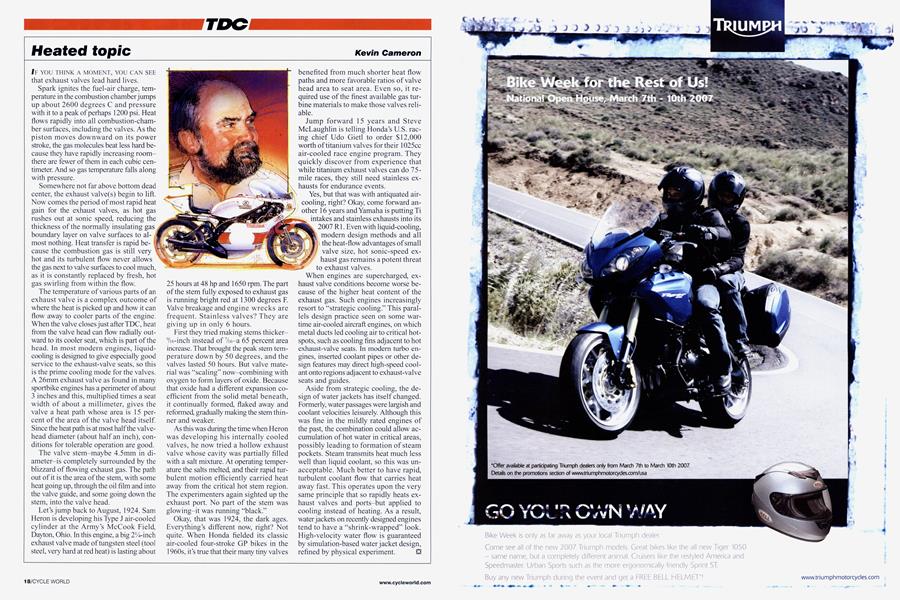

Heated topic

Kevin Cameron

TDC

IF YOU THINK A MOMENT, YOU CAN SEE that exhaust valves lead hard lives.

Spark ignites the fuel-air charge, temperature in the combustion chamber jumps up about 2600 degrees C and pressure with it to a peak of perhaps 1200 psi. Heat flows rapidly into all combustion-chamber surfaces, including the valves. As the piston moves downward on its power stroke, the gas molecules beat less hard because they have rapidly increasing roomthere are fewer of them in each cubic centimeter. And so gas temperature falls along with pressure.

Somewhere not far above bottom dead center, the exhaust valve(s) begin to lift. Now comes the period of most rapid heat gain for the exhaust valves, as hot gas rushes out at sonic speed, reducing the thickness of the normally insulating gas boundary layer on valve surfaces to almost nothing. Heat transfer is rapid because the combustion gas is still very hot and its turbulent flow never allows the gas next to valve surfaces to cool much, as it is constantly replaced by fresh, hot gas swirling from within the flow.

The temperature of various parts of an exhaust valve is a complex outcome of where the heat is picked up and how it can flow away to cooler parts of the engine. When the valve closes just after TDC, heat from the valve head can flow radially outward to its cooler seat, which is part of the head. In most modern engines, liquidcooling is designed to give especially good service to the exhaust-valve seats, so this is the prime cooling mode for the valves. A 26mm exhaust valve as found in many sportbike engines has a perimeter of about 3 inches and this, multiplied times a seat width of about a millimeter, gives the valve a heat path whose area is 15 percent of the area of the valve head itself. Since the heat path is at most half the valvehead diameter (about half an inch), conditions for tolerable operation are good.

The valve stem-maybe 4.5mm in diameter-is completely surrounded by the blizzard of flowing exhaust gas. The path out of it is the area of the stem, with some heat going up, through the oil film and into the valve guide, and some going down the stem, into the valve head.

Let’s jump back to August, 1924. Sam Heron is developing his Type J air-cooled cylinder at the Army’s McCook Field, Dayton, Ohio. In this engine, a big 2%-inch exhaust valve made of tungsten steel (tool steel, very hard at red heat) is lasting about 25 hours at 48 hp and 1650 rpm. The part of the stem fully exposed to exhaust gas is running bright red at 1300 degrees F. Valve breakage and engine wrecks are frequent. Stainless valves? They are giving up in only 6 hours.

First they tried making stems thicker9/i6-inch instead of 7/i6—a 65 percent area increase. That brought the peak stem temperature down by 50 degrees, and the valves lasted 50 hours. But valve material was “scaling” now-combining with oxygen to form layers of oxide. Because that oxide had a different expansion coefficient from the solid metal beneath, it continually formed, flaked away and reformed, gradually making the stem thinner and weaker.

As this was during the time when Heron was developing his internally cooled valves, he now tried a hollow exhaust valve whose cavity was partially filled with a salt mixture. At operating temperature the salts melted, and their rapid turbulent motion efficiently carried heat away from the critical hot stem region. The experimenters again sighted up the exhaust port. No part of the stem was glowing-it was running “black.”

Okay, that was 1924, the dark ages. Everything’s different now, right? Not quite. When Honda fielded its classic air-cooled four-stroke GP bikes in the 1960s, it’s true that their many tiny valves

benefited from much shorter heat flow paths and more favorable ratios of valve head area to seat area. Even so, it required use of the finest available gas turbine materials to make those valves reliable.

Jump forward 15 years and Steve McLaughlin is telling Honda’s U.S. racing chief Udo Gietl to order $12,000 worth of titanium valves for their 1025cc air-cooled race engine program. They quickly discover from experience that while titanium exhaust valves can do 75mile races, they still need stainless exhausts for endurance events.

Yes, but that was with antiquated aircooling, right? Okay, come forward an7 other 16 years and Yamaha is putting Ti intakes and stainless exhausts into its 2007 R1. Even with liquid-cooling, I modern design methods and all ii the heat-flow advantages of small / valve size, hot sonic-speed exhaust gas remains a potent threat to exhaust valves.

When engines are supercharged, exhaust valve conditions become worse because of the higher heat content of the exhaust gas. Such engines increasingly resort to “strategic cooling.” This parallels design practice seen on some wartime air-cooled aircraft engines, on which metal ducts led cooling air to critical hotspots, such as cooling fins adjacent to hot exhaust-valve seats. In modem turbo engines, inserted coolant pipes or other design features may direct high-speed coolant onto regions adjacent to exhaust-valve seats and guides.

Aside from strategic cooling, the design of water jackets has itself changed. Formerly, water passages were largish and coolant velocities leisurely. Although this was fine in the mildly rated engines of the past, the combination could allow accumulation of hot water in critical areas, possibly leading to formation of steam pockets. Steam transmits heat much less well than liquid coolant, so this was unacceptable. Much better to have rapid, turbulent coolant flow that carries heat away fast. This operates upon the very same principle that so rapidly heats exhaust valves and ports-but applied to cooling instead of heating. As a result, water jackets on recently designed engines tend to have a “shrink-wrapped” look. High-velocity water flow is guaranteed by simulation-based water jacket design, refined by physical experiment. □