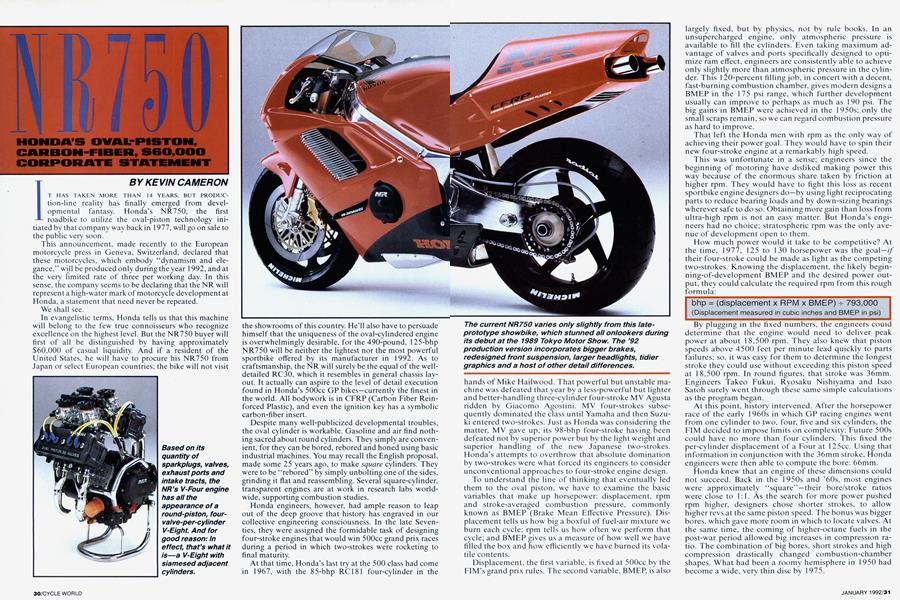

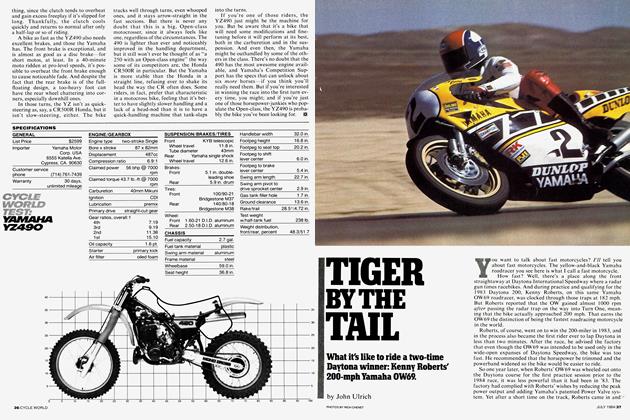

NR 750

HONDA'S OVAL-PISTON, CARBON-FIBER, $60,000 CORPORATE STATEMENT

KEVIN CAMERON

IT HAS TAKEN MORE THAN 14 YEARS, BUT PRODUCtion-line reality has finally emerged from devel opmental fantasy. Honda's NR750, the first roadbike to utilize the oval-piston technology initiated by that company way back in 1977, will go on sale to the public very soon.

This announcement, made recently to the European motorcycle press in Geneva, Switzerland, declared that these motorcycles, which embody "dynamism and ele gance," will be produced only during the year 1992, and at the very limited rate of three per working day. In this sense, the company seems to be declaring that the NR will represent a high-water mark of motorcycle development at Honda, a statement that need never be repeated.

We shall see.

In evangelistic terms, Honda tells us that this machine will belong to the few true connoisseurs who recognize excellence on the highest level. But the NR750 buyer will first of all be distinguished by having approximately $60,000 of casual liquidity. And if a resident of the United States, he will have to procure his NR750 from Japan or select European countries; the bike will not visit

the showrooms of this country. He'll also have to persuade himself that the uniqueness of the oval-cylindered engine is overwhelmingly desirable, for the 490-pound, 125-bhp NR750 will be neither the lightest nor the most powerful sportbike offered by its manufacturer in 1992. As to craftsmanship, the NR will surely be the equal of the well detailed RC3O, which it resembles in general chassis lay out. It actually can aspire to the level of detail execution found in Honda's 500cc GP bikes-currently the finest in the world. All bodywork is in CFRP (Carbon Fiber Rein forced Plastic), and even the ignition key has a symbolic carbon-fiber insert.

Despite many well-publicized developmental troubles, the oval cylinder is workable. Gasoline and air find noth ing sacred about round cylinders. They simply are conven ient, for they can be bored, rebored and honed using basic industrial machines. You may recall the English proposal, made some 25 years ago, to make square cylinders. They were to be "rebored" by simply unbolting one of the sides, grinding it flat and reassembling. Several square-cylinder, transparent engines are at work in research labs world wide, supporting combustion studies.

had ample reason to leap out of the deep groove that history has engraved in our collective engineering consciousness. In the late Seven ties, they were assigned the formidable task of designing four-stroke engines that would win 500cc grand prix races during a period in which two-strokes were rocketing to final maturity.

At that tinie, Honda's last try at the 500 class had come in 1967, with the 85-bhp RC181 four-cylinder in the hands of Mike Hailwood. That powerful but unstable ma chine was defeated that year by a less-powerful but lighter and better-handling three-cylinder four-stroke MV Agusta ridden by Giacomo Agostini. MV four-strokes subse quently dominated the class until Yamaha and then Suzu ki entered two-strokes. Just as Honda was considering the matter, MV gave up, its 98-bhp four-stroke having been defeated not by superior power but by the light weight and superior handling of the new Japanese two-strokes. Honda's attempts to overthrow that absolute domination by two-strokes were what forced its engineers to consider unconventional approaches to four-stroke engine design.

To understand the line of thinking that eventually led them to the oval piston, we have to examine the basic variables that make up horsepower: displacement, rpm and stroke-averaged combustion pressure. commonly known as BMEP (Brake Mean Effective Pressure). Dis placement tells us how big a boxful of fuel-air mixture we burn each cycle; rpm tells us how often we perform that cycle; and BMEP gives us a measure of how well we have filled the box and how efficiently we have burned its vola tile contents.

Displacement, the first variable, is fixed at 500cc by the FIM's grand prix rules. The second variable, BMEP, is also

largely fixed, but by physics, not by rule books. In an unsupercharged engine, only atmospheric pressure is available to fill the cylinders. Even taking maximum ad vantage of valves and ports specifically designed to opti mize ram effect, engineers are consistently able to achieve only slightly more than atmospheric pressure in the cylin der. This 120-percent filling job, in concert with a decent, fast-burning combustion chamber, gives modern designs a BMEP in the 175 psi range, which further development usually can improve to perhaps as much as 190 psi. The big gains in BMEP were achieved in the 1 950s; only the small scraps remain, so we can regard combustion pressure as hard to improve.

That left the Honda men with rpm as the only way of achieving their power goal. They would have to spin their new four-stroke engine at a remarkably high speed.

This was unfortunate in a sense; engineers since the beginning of motoring have disliked making power this way because of the enormous share taken by friction at higher rpm. They would have to fight this loss as recent sportbike engine designers do-by using light reciprocating parts to reduce bearing loads and by down-sizing bearings wherever safe to do so. Obtaining more gain than loss from ultra-high rpm is not an easy matter. But Honda's engi neers had no choice; stratospheric rpm was the only ave nue of development open to them.

How much power would it take to be competitive? At the time, 1977, 125 to 130 horsepower was the goal-if their four-stroke could be made as light as the competing two-strokes. Knowing the displacement, the likely begin ning-of-development BMEP and the desired power out put, they could calculate the required rpm from this rough formula:

bhp = (displacement x RPM x BMEP) ÷ 793,000 (Displacement measured in cubic inches and BMEP in psi)

By plugging in the fixed numbers, the engineers could determine that the engine would need to deliver peak power at about 18,500 rpm. They also knew that piston speeds above 4500 feet per minute lead quickly to parts failures; so, it was easy for them to determine the longest stroke they could use without exceeding this piston speed at 18,500 rpm. In round figures, that stroke was 36mm. Engineers Takeo Fukui, Ryosaku Nishiyama and Isao Satoh surely went through these same simple calculations as the program began.

At this point, history intervened. After the horsepower race of the early 1 960s in which GP racing engines went from one cylinder to two, four, five and six cylinders, the FIM decided to impose limits on complexity: Future 500s could have no more than four cylinders. This fixed the per-cylinder displacement of a Four at 125cc. Using that information in conjunction with the 36mm stroke, Honda engineers were then able to compute the bore: 66mm.

Honda knew that an engine of these dimensions could not succeed. Back in the I 950s and `60s, most engines were approximately "square"-their bore/stroke ratios were close to 1: 1. As the search for more power pushed rpm higher, designers chose shorter strokes, to allow higher revs at the same piston speed. The bonus was bigger bores, which gave more room in which to locate valves. At the same time, the coming of higher-octane fuels in the post-war period allowed big increases in compression ra tio. The combination of big bores, short strokes and high compression drastically changed combustion-chamber shapes. What had been a roomy hemisphere in 1950 had become a wide, very thin disc by 1975.

This difference in combustion-chamber shape is signifi cant. The flame speed of a motionless, correct fuel-air mixture isn't much-about one foot per second. But to complete its combustion in the short time available in an engine, the mixture must be made to burn far faster than this-two to three hundred times faster. This accelerated burning is accomplished by turbulence in the mixture, which speeds up the flame by wrinkling the flame front and increasing its area so vastly that it consumes mixture at a greatly accelerated rate. The turbulence comes mainly from the leftover energy of the intake flow, which persists through the compression and combustion cycles.

In the old, roomy chambers, there was little to stop this turbulent motion. But in the new, big-bore, high-compres sion chambers, the combustion space is so thin and wide that turbulence dies out quickly.

Slow combustion is the result, and it is manifested as a need for excessive ignition advance. A classic example is the 1990 OWO1 Yamaha 750 race engine, with a bore! stroke ratio of 1 .66: 1: It uses 45 degrees of spark lead. With combustion taking this long, much of the charge is burned when the piston is far from the head, so the "effec tive compression ratio" at which it is burned is quite low. Long combustion also robs heat from the burning gases, reducing their push on the piston. As a consequence, such engines don't produce the high BMEP their designers would like.

This problem-how to make short-stroke, big-bore cyl inders burn fast and efficiently-is the central problem in racing four-stroke engine design today. Engineers want a short stroke so engines can rev to big numbers without exceeding the piston speed of reasonable reliability, and they want a big bore in which to locate the necessary large valve area. But they don't want the slow-burning, ugly, inefficient combustion chamber that results from extreme combinations of the two.

Honda has deep background in ultra-high-rpm combus tion. Back in 1965, its engineers built a family of engines of various sizes with bore/stroke ratios of about 1. 1 5: 1, and they tested them to their limiting piston speeds (read about it in SAE Paper 700122, by S. Yagi et a!., "Research and Development of High-Speed, High-Performance, Small Displacement Honda Engines"). They found that combustion kept pace with rpm perfectly well all the way to 27,000 rpm; the test engines didn't need increasing spark lead as they revved up. This is because intake-gener ated charge motion and turbulence increase with rpm, car rying flame speed with them.

Fine, except that the FIM's four-cylinder rule and the need for a very short, 36mm stroke prevented Honda from

making direct use of this knowledge. Those 1965 tests. involved almost "square" engines, which had plenty of room above their pistons at TDC for charge turbulence.

Consider, for e'xample, the following I~tmily of 500cc engines with square bore/stroke dimensions. This chart shows their power potentials when run to 4500 feet-per minute piston speed, with an early-development BMEP of 175 psi:

This was very discouraging. For Honda to get even near its horsepower goal with a square engine, it would have had to build a hideously complex. bulky and surely very heavy V-12. Forget that.

Bti't there still was hope. Keith Duckworth, in his Cosworth DFV Formula One auto-racing engine, showed how to maintain excellent combustion efficiency up to a bore/stroke ratio of 1.3: 1 by using four valves set at a narrow included angle. with a central sparkplug. This would allow a mere 500cc V-Eight to have good, rapid combustion with bore/stroke dimensions of 47 x 36mm. Here's how the 5 00cc engine family looks with bore/stroke ratios of 1.3:1:

Note the data for the four-cylinder: They describe a! most exactly the last engine tested but not raced by MV Agusta just as that marque gave up the game as lost in the middle 1 970s. This table suggests that, by diligent devel opment, the power goal might be reached with six or eight cylinders. But the FIM limit is four.

Now let's push on to the current "leading edge" in out rageous bore/stroke ratio: 1.5: 1. Up in this region, Suzuki found the limit beyond which losses outweighed gains. Yamaha and Ducati are still struggling to achieve efficient combustion at or beyond a 1.5:1 bore/stroke ratio. Here is the 500cc family at 1.5:1:

Again, this is discouraging. Even with a design so oversquare as to invite proven combustion-efficiency problems, it would take six cylinders to do the job. How could the Honda engineers burn that awful, 66 x 36mm cylinder that FIM rules seemed to be forcing upon them? Its bore/stroke ratio was right off the deep end at 1.83: 1!

One tempting possibility would be to speed up combus tion by adding more sparkplugs in each combustion cham ber. After all, this had worked to perk up two-valve en gines. But there is no place for more plugs with four valves. Would more plugs fit with more valves? Sadly, current experience shows that the more holes are put into a head, the more certain it is to deform or crack in operation. Four or five valves with a central plug seems optimum.

That put the engineers in a box.A central plug gave minimum flame-travel distance, but not short enough.

Ah, but that's true only in a round cylinder. What about some other shape? What if they squeezed the cylinder into an oval, making it look awfully like two cylinders that had grown together. So, the engineers sketched just such a lay out: Hmmm, put four valves in each "half" of this oblong chamber, and put one sparkplug in the center of each group of valves. In that instant of unconventional thought, they achieved the short flame travel they sought-equivalent to the V-Eight rejected earlier. That solved the combustion-efficiency problem.

Of course, this radical, oval-p~s~on idea also created nu merous other engineering challenges. The resulting pis tons were so wide that they seemed to demand two con rods. And what about boring oval cylinders? Shouldn't be a problem: The people who make Wankel engines can make "cylinders" in any shape you want. How can we seal the pistons? Again, if they can seal up those unlikely Wan ket contraptions, we ought to be able to seal oval cylinders.

Honda's engineers then began the tedious process of developing their idea. They first built a proof-of-concept top end on an XL250 crankcase, then built a special en gine from the ground up to test the twin-con-rod idea. Then came a series of 500cc racing engines, built as V Fours because the oval cylinders were too wide for an inline design. The pistons measured 93.4mm side-to-side and 41mm front-to-back, working through a 36mm stroke.

By July of 1979, the first of these engines, called the OX, had reached the lOO-bhp level. The NR500 motorcy cle it powered, incorporating innovations such as 16-inch wheels, aluminum monocoque chassis, side radiators and an inverted fork, was entered in GP racing. -

The results were terrible. The bike was heavy, it had so little flywheel mass that it tended to stall in corners, it was hard to start, and its power was up high in the rpm band. At the British GP in August of `79, veterans Mick Grant and Takazumi Katayama rode the machines, which were embarrassingly slow and did not finish. At the French GP three weeks later, they failed even to qualify.

Meanwhile, the OX engine reached 11 5~ bhp, and the next design iteration, the 1X, was begun. In January of 1980 it achieved 120 bhp. For reasons of practicality, the 16-inch wheels and monocoque chassis of the 1979 bike were replaced with conventional, GP-proven items.

Now the bike began to finish races, but far back. Honda was pushing development rapidly, but the two-stroke op position was working equally hard, leaving the Honda equally far behind. The oval-piston machines were dense concentrations of the very finest industrial R&D; at Euro pean border crossings, their declared value was stated as one million dollars each.

At season's end, the 2X design was begun. By the end of yet another undistinguished season, this engine reached 130 bhp at 18,500 rpm. The NR500 was still heavy and smoky. but had a great sound-almost indistinguishable from that of its two-stroke competition.

This was no accident: with an engine firing half as often but turning almost twice as fast, the exhaust pulses reach the listener's ear at about the same frequency. At idle, it had the muscular growl of a Superbike, accompanied by a vast mechanical whirring and ticking.

By 1982, the NR500 had achieved much better reliabil ity but remained uncompetitive, generally finishing out of the top 10. Freddie Spencer had pushed the bike to as high as fifth in the British GP only to suffer mechanical failure once again.

Nevertheless, this was not the disaster it appears. I he early history of Honda's turbocharged Formula One V-Six auto-racing motor was even worse; but persisting through seemingly endless failures, the engineers achieved success that turned shortly into complete dominance.

This is because mechanical systems are never easy to develop; it takes irrational persistence to make some things work. As company founder Soichiro Honda noted, there is no success for those who cannot tolerate failure. But in these efforts to make a four-stroke competitive in motor cycle GP racing, even mighty Honda had to admit-it was swinging two bats in a game against strong opposition. The company therefore withdrew the NR500 and split its ovalpiston development two ways: First, the NR250 turbo charged Twin was initiated for a possible GP future; sec ond, an NR750 was prepared for endurance racing. And the enormously innovative NS500 two-stroke was com mitted to GP racing in the NR's place. This motorcycleunderpowered but light and handy-was ridden to the World Championship by Freddie Spencer in 1983.

It's easy to dismiss the NR program as a loss, but it did provide one solution to the problem of how to efficiently burn a large-area combustion chamber at very high rpm. It also produced innovative work in sealing and friction-re duction. Had Honda simply applied this technology at full strength to the endurance-racing NR750 project, the re sult might have been as much as 170 bhp up at 16,500 rpm. Instead, the engineers decided to trade away some of the all-out power potential (scaling it down to 156-160 bhp) to obtain unprecedented flexibility.

`i'his meant shortening cam timings nd reducing valve lift. The result had a quite different character from that of

the 500. Whereas the 500 had its power up high, the 750 is described as having power everywhere and revving "seem ingly forever." In an era when the highly developed, round-piston racing RC3O had become peaky and difficult to ride, oval-piston technology offered a new freedom to combine rower and flexibility.

Honda did not expect much of the machine in endur ance trim, however, sending it off to race at Le Mans in the hands of journalists. Even so, it qualified second before retiring in the race. So, in retrospect, the NR750 endur ance-racing effort seems to have been a technological pub lic-relations balloon rather than a serious racing program.

Since then, there have been constant rumors~f produc tion Hondas with oval cylinders. Now the moment has come. The bike introduced at Geneva is a road machine, detuned from the 160 bhp of the endurance-racing NR75Odownto l25ata'mere" 14,000rpm.

These numbers are a testimony to what oval-piston technology has achieved. While recent RC3O round-pis ton racing engines (and their competition) strain to reach 14,000 rpm. the road-going NR750 is detuned down to this level. Built on an RC3O-like chassis with all the expected features, it has a claimed dry weight of 490 pounds. Atop the V-Four engine sits a complex, eight-throttle-body elec tronic fuel-injection system. A reminder of racing inten tions and ambitions is the quickly removable, cassette style six-speed gearbox.

Many industry observers had expected this technology to appear in high-end street motorcycles for low-volume mass production, and at a price of perhaps $ 15,000. But Honda has decided to offer it instead to the Bimota-class buyer-at the higher price and essentially hand-assembled.

Since the FIM has now decided that international racing will, in the near future, cater only to round-cylindered engines, the NR has become an expensive, historic and maximally exotic piece of R&D history-before it ever hits the streets.

Order now, while supplies last.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontSectional Harassment

January 1992 By David Edwards -

Leanings

LeaningsWind On the Chin

January 1992 By Peter Egan -

TDC

TDCPumped

January 1992 By Kevin Cameron -

Letters

LettersLetters

January 1992 -

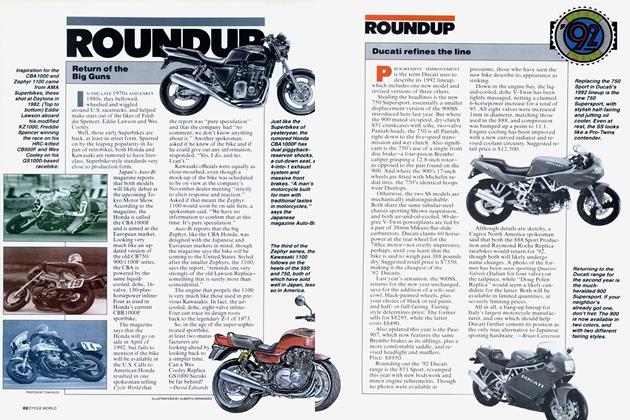

Roundup

RoundupReturn of the Big Guns

January 1992 By David Edwards -

Roundup

RoundupDucati Refines the Line

January 1992 By Brian Catterson