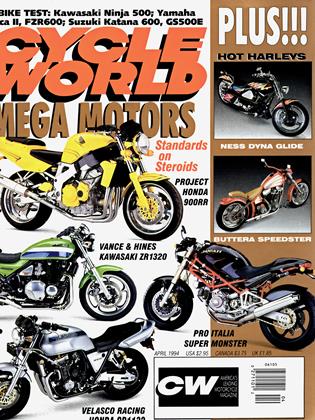

Class struggles

TDC

Kevin Cameron

WHY DO WE CLASS MOTORCYCLES BY engine displacement? Easy answer: It lets advertisers say things like “Fastest (or Lightest, Sweetest-Smelling, etc.) 600 on the market.” Historically, we might find the importance of displacement derives from the weakness of governments for taxation. English machines were taxed on the basis of a horsepower formula that was really, just cylinder displacement, multiplied times an arbitrary constant.

“Well,” you may say, “Isn’t it obvious that the bigger the displacement, the greater the performance you get? Isn’t that what we're paying for?” If we are talking about drag racing, maybe, but if we choose other performance criteria (like weight or price or fuel efficiency or who’s first up the ‘Crest Highway), displacement tells us almost nothing.

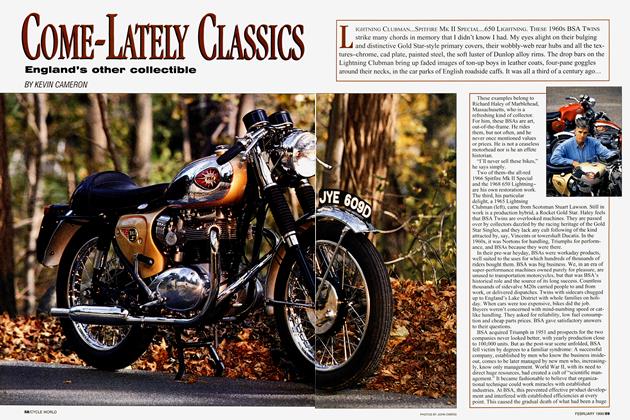

Tease out another historical thread: racing. Racing has generally classed machinery by displacement-mainly because displacement is easily measured without argument. But it’s surprising that displacement is still considered useful, despite the number of times that particular apple cart has been dumped over. For example, so long as 500cc racing consisted of nearly identical overhead-cam Singles, displacement was meaningful to the extent that no one’s engine could seriously outrev or outbreathe anyone else’s. But in the late 1930s along came BMW’s Twin and the Italian Fours-all with strokes much shorter than the old Singles, enabling them to rev far higher, filling and burning their cylinders much more often than could the Singles. Yet for some reason people remained satisfied with the spectacle of Mr. Wonderful leading by a mile on a four-cylinder bike that performed its power-producing cycle almost twice as often as the pursuing host of Singles.

The next big apple spill began in the 1950s and wasn’t completed until 1976. In 1930, two-stroke engines were a poor second choice as a motorcycle powerplant-sputtering, plugfouling economy piles that conferred negative prestige upon their owners. By 1958, the two-stroke had evolved into a kind of trick technological grenade-fast for five or 10 laps, maybe, but sure to foul or blow, certainly no match conceptually, physically or spiritually for the superbly developed four-stroke Singles and Multis of that time. Then in the early 1960s, rapidly improving two-strokes began to eat world roadracing championships instead of pistons, first in the smaller classes, but spreading upward. Today, a four-cylinder two-stroke 500 racer produces 170-180 horsepower, while an equivalent four-stroke 500, highly developed, might reach 125.

Clearly, then, displacement is no miracle of accurate comparison. Should we be surprised that an apple and an orange that both measure the same diameter can taste so different?

The world of streetbikes, being an economic activity, responds to displacement classification somewhat differently. Manufacturer A builds a nice little 500 with good handling and surprising power for its size. Maker B replies with more gadgets on his 500, pushing the power up a bit. Buyers switch to B. Maker A considers the options: Shall we add those same expensive gadgets in trying to top B? The engineers point out that simply turning the knob on the boring machine can produce a 550cc engine that is both quicker and easier to ride than those gadgetty, high-revving, peaky B bikes. Because the engine is bigger only in bore, the bike weighs no more than before so handling remains good. It doesn’t cost much to bore bigger cylinders, so the price rises only a teeny bit. Buyers switch back to A.

Now Manufacturer B sees the light, and its engineers stride purposefully

to their boring machines. Okay, it’s not quite that simple; the cylinder casting has to be revised a bit, and bigger pistons must be made, and there may also have to be miscellaneous strengthenings here and there to handle the extra poke. But it’s a lot cheaper to make a decent design a little bigger than it is to retool from two valves to four, from one cam to two, or from two cylinders to four. A lot cheaper. So Maker B now releases a 600, which outperforms A’s 550. The buyers surge back again. And so on.

The terrible thing about arbitrary displacement limits is that they force engineers to make horsepower the hard way. Horsepower is proportional to displacement, times average combustion pressure, times rpm. Displacement limits lock that variable down, and with only our 15 psi atmosphere to shove air into the cylinders, combustion pressure is also limited (unless we turn to supercharging or rocket fuel). That leaves only rpm to play with. And how they play! The engineers push the revs up, and friction’s frightful jaws open wide, devouring more and more of the power that the machinery is hammering so hard to produce. Inertia forces rise, threatening to break the parts, so we make them tricker, thicker—and heavier and more expensive.

Stop. By simply stepping out of the displacement scheme, an engineer can find a more rational way to achieve power. Instead of putting all that extra weight into hefty crankcases and mightily braced cylinders and the ingenious machinery needed to pump air in and out of them at superduper rpm, he can put that same weight into a lowerstressed, slower-turning, larger-displacement design. Because its power doesn’t depend upon turning a zillion revs and squeezing the last psi of combustion pressure out of elusive, narrowband intake and exhaust resonances, it can have a dandy wide powerband that anyone can use without having to be a throttle-and-gearbox genius.

I agree that displacement limits can be, as Lolita said, “kind of fun,” with their enforced mad search for power through rpm. It’s exciting to see how far the makers will go each year with their new 750s. But it’s also useful to remember that there are other possible ways to achieve power or classify performance. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontHigher Standards

April 1994 By David Edwards -

Leanings

LeaningsShould You Buy A German Bike?

April 1994 By Peter Egan -

Letters

LettersLetters

April 1994 -

Roundup

RoundupVr Harley Superbike For the Street?

April 1994 By Kevin Cameron -

Roundup

RoundupVr 1000 Parts For the People

April 1994 By Robert Hough -

Roundup

RoundupBritten Breaks Records, Builds Bikes

April 1994 By Robert Hough