Back to Nature

TDC

Kevin Cameron

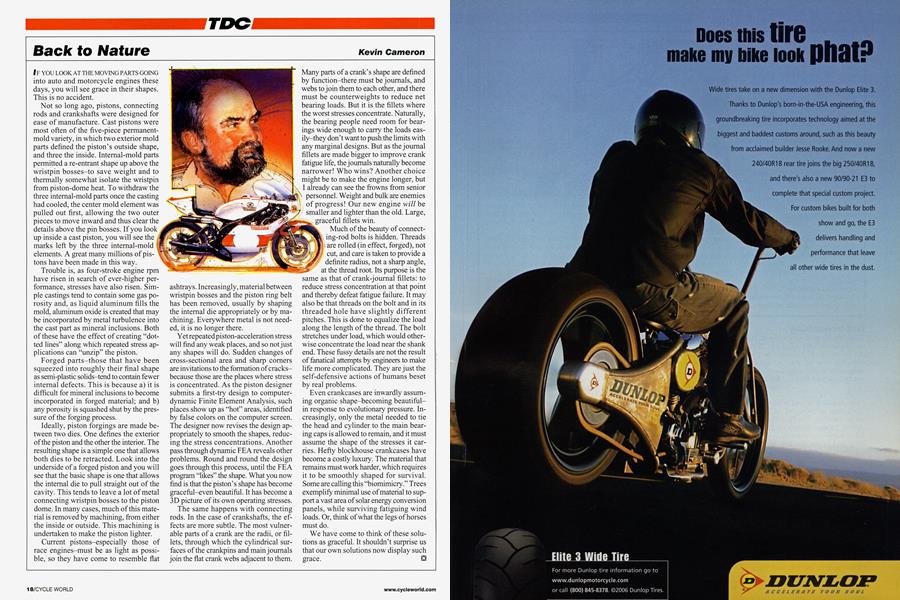

IF YOU LOOK AT THE MOVING PARTS GOING into auto and motorcycle engines these days, you will see grace in their shapes. This is no accident.

Not so long ago, pistons, connecting rods and crankshafts were designed for ease of manufacture. Cast pistons were most often of the five-piece permanent-mold variety, in which two exterior mold parts defined the piston’s outside shape, and three the inside. Internal-mold parts permitted a re-entrant shape up above the wristpin bosses-to save weight and to thermally somewhat isolate the wristpin from piston-dome heat. To withdraw the three internal-mold parts once the casting had cooled, the center mold element was pulled out first, allowing the two outer pieces to move inward and thus clear the details above the pin bosses. If you look up inside a cast piston, you will see the marks left by the three internal-mold elements. A great many millions of pistons have been made in this way.

Trouble is, as four-stroke engine rpm have risen in search of ever-higher performance, stresses have also risen. Simple castings tend to contain some gas porosity and, as liquid aluminum fills the mold, aluminum oxide is created that may be incorporated by metal turbulence into the cast part as mineral inclusions. Both of these have the effect of creating “dotted lines” along which repeated stress applications can “unzip” the piston.

Forged parts-those that have been squeezed into roughly their final shape as semi-plastic solids-tend to contain fewer internal defects. This is because a) it is difficult for mineral inclusions to become incorporated in forged material; and b) any porosity is squashed shut by the pressure of the forging process.

Ideally, piston forgings are made between two dies. One defines the exterior of the piston and the other the interior. The resulting shape is a simple one that allows both dies to be retracted. Look into the underside of a forged piston and you will see that the basic shape is one that allows the internal die to pull straight out of the cavity. This tends to leave a lot of metal connecting wristpin bosses to the piston dome. In many cases, much of this material is removed by machining, from either the inside or outside. This machining is undertaken to make the piston lighter.

Current pistons-especially those of race engines-must be as light as possible, so they have come to resemble flat ashtrays. Increasingly, material between wristpin bosses and the piston ring belt has been removed, usually by shaping the internal die appropriately or by machining. Everywhere metal is not needed, it is no longer there.

Yet repeated piston-acceleration stress will find any weak places, and so not just any shapes will do. Sudden changes of cross-sectional area and sharp comers are invitations to the formation of cracksbecause those are the places where stress is concentrated. As the piston designer submits a first-try design to computerdynamic Finite Element Analysis, such places show up as “hot” areas, identified by false colors on the computer screen. The designer now revises the design appropriately to smooth the shapes, reducing the stress concentrations. Another pass through dynamic FEA reveals other problems. Round and round the design goes through this process, until the FEA program “likes” the shape. What you now find is that the piston’s shape has become graceful-even beautiful. It has become a 3D picture of its own operating stresses.

The same happens with connecting rods. In the case of crankshafts, the effects are more subtle. The most vulnerable parts of a crank are the radii, or fillets, through which the cylindrical surfaces of the crankpins and main journals join the flat crank webs adjacent to them.

Many parts of a crank’s shape are defined by function-there must be journals, and webs to join them to each other, and there must be counterweights to reduce net bearing loads. But it is the fillets where the worst stresses concentrate. Naturally, the bearing people need room for bearings wide enough to carry the loads easily-they don’t want to push the limits with any marginal designs. But as the journal fillets are made bigger to improve crank fatigue life, the journals naturally become narrower! Who wins? Another choice might be to make the engine longer, but I already can see the frowns from senior personnel. Weight and bulk are enemies of progress! Our new engine will be smaller and lighter than the old. Large, graceful fillets win.

Much of the beauty of connect; ing-rod bolts is hidden. Threads are rolled (in effect, forged), not cut, and care is taken to provide a definite radius, not a sharp angle, at the thread root. Its purpose is the same as that of crank-journal fillets: to reduce stress concentration at that point and thereby defeat fatigue failure. It may also be that threads on the bolt and in its threaded hole have slightly different pitches. This is done to equalize the load along the length of the thread. The bolt stretches under load, which would otherwise concentrate the load near the shank end. These fussy details are not the result of fanatical attempts by engineers to make life more complicated. They are just the self-defensive actions of humans beset by real problems.

Even crankcases are inwardly assuming organic shape-becoming beautifulin response to evolutionary pressure. Increasingly, only the metal needed to tie the head and cylinder to the main bearing caps is allowed to remain, and it must assume the shape of the stresses it carries. Hefty blockhouse crankcases have become a costly luxury. The material that remains must work harder, which requires it to be smoothly shaped for survival. Some are calling this “biomimicry.” Trees exemplify minimal use of material to support a vast area of solar energy conversion panels, while surviving fatiguing wind loads. Or, think of what the legs of horses must do.

We have come to think of these solutions as graceful. It shouldn’t surprise us that our own solutions now display such grace.