TDC

Making it easy

Kevin Cameron

How DO YOU MAKE A BIG, POWERFUL motorcycle easy to ride? The obvious answer is that you allow the operator to decide exactly how “big” the bike should act at any moment. In other words, you make it accurately and predictably controllable.

One of the first problems riders and tuners had with the 1025cc AMA Superbikes of the late 1970s was “throttle pop.” While streetbikes had CV carbs with butterfly throttles, the high-performance fuel system of that era was the slide-throttle carburetor. Its special problem was that at idle, engine vacuum strongly held the throttle slides down against their stops. When the rider wanted to feed in smooth, controllable power from full lean in a turn, what resulted instead was a sudden POP! as the necessarily high throttle-cable tension broke the vacuum on the slides and they shot upward. Such a sudden throttle pulse in mid-corner was upsetting.

All kinds of schemes were put in hand to equalize the vacuum on top and bottom of all slides, but this left intake vacuum still strongly pulling the slides against their guides. This in turn produced a rash of slides coated with antifriction material, or slides moving on clever rollers. The results were never entirely satisfactory. Finally, along came the fuel-injection era. Slide throttles are great if maximum undisturbed airflow is the goal, but butterfly throttles-with the forces on them balanced and their shafts easily adapted to ball bearings-operate much more easily.

Next problem is idle and part-throttle “exhaust fraction.” All sorts of waves are bouncing around in an engine’s intake and exhaust systems, and at the rpm of throttle-up in corners it may be that it is a positive exhaust pressure pulse that is arriving at TDC, during valve overlap at the end of the exhaust stroke. This positive wave stuffs incombustible exhaust gas into the combustion chamber at the last moment, as the exhaust valves close. Since the throttle is almost closed, very little fresh charge is being admitted. Will the resulting mixture of exhaust and fresh charge ignite? The answer is often no. As a result, the engine misfires to some degree. But 50 or 100 rpm higher up, as the bike accelerates, wave action in the pipe may shift, delivering a negative wave instead. This sucks exhaust product out of the combustion chamber, creating a low pressure into which fresh charge rushes from the just-opening intake valves. Now the engine goes from a hesitant, gargling misfire to pulling quite strongly. This torque surge, if it doesn’t actually kick the rear tire out, will at least give the rider serious stuff to think about-just when he doesn’t need it.

The easy fix for this one is to reduce the overlap timing-the period near TDC after the exhaust stroke when both intakes and exhausts are open together. The shorter the overlap timing, the less time and valve opening there is through which exhaust or intake waves can affect cylinder contents.

But wait! Valve overlap is a primary tool of higher-rpm cylinder filling. Is smooth throttle-up for an early drive off corners worth a sacrifice of top power? Maybe it isn’t necessary. If you look at the exhaust systems of the current lOOOcc sportbike Fours you'll see that they have moveable, motor-operated gates where headers join the rest of the pipe. At part-throttle these valves close down to act as wave dampers, killing the pipe waves that can cause exhaust fraction misfire.

Now how about basic state of tune? We know that as an engine revs up, we'd like to keep the intake valves open longer and longer, to provide the extra flow needed to fill the cylinders as there is less and less time in which to fill them. This is why everyone in the car biz is playing with some form of variable valve timing. That’s not ready for bikes yet so we have to compromise. If we choose quite early closure, we have really good bottom and midtorque, but the engine is weak on top. Who buys a lOOOcc motorcycle for weak top-end? Nobody! We decide to close the intakes a bit later. By so doing, we lose something at the bottom but gain at the top. This may be okay; after all, we don’t want our engine to come on so hard from the bottom-end that it upsets riders.

Motorbikes are a competitive business-every maker has to push to “hit the numbers” in order to be bike of the month. At some point, engines are tuned so highly they begin to be harder to ride. Late intake closure makes the bottom torque weak, but then it slopes upward steeply as the engine “comes on the cam.” This steepness in itself is a problem-it can take us by surprise, as if someone else was opening the throttle for us. So now the cam dynamics group tells us they can fill the cylinder more evenly across the whole rev range by a) increasing valve area and b) shortening valve-open timing. But to accomplish b) at the same revs as before requires higher valve accelerations. No problem, we lighten the valves 40 percent by making them of titanium, we use trendy tapered “beehive” valve springs, we optimize everything. Soon we’re okay again-power is smooth, torque curve doesn’t slope upward too steeply, our bike is very rideable.

The trouble is, our competitors know the same stuff we know, and have made the same changes. Now where’s our advantage?

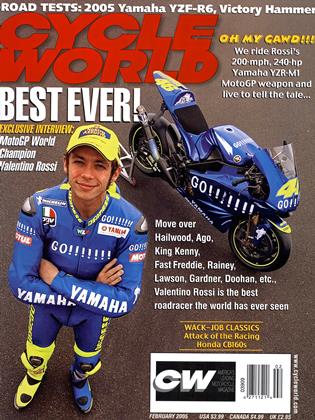

This is roughly the situation in MotoGP right now. The Honda makes a lot of power but pays for it down low, where it’s a little rough. The Yamaha is very smooth and strong in early throttle-up, but is barely hanging on down the longest straights. To combine both these desirable performance regimes will require even higher valve accélérations-accélérations that may be reliably attainable only with pneumatic springs (I say reliably because one MotoGP team at least is already breaking a lot of springs). Who’ll be first to win in MotoGP with pneumatics?

View Full Issue

View Full Issue

More From This Issue

-

Columns

ColumnsUp Front

February 2005 By David Edwards -

Leanings

LeaningsThe Fine Art of Planning To Crash

February 2005 By Peter Egan -

Departments

DepartmentsHotshots

February 2005 -

Roundup

RoundupMoto Morini Lives!

February 2005 By Brian Catterson -

Roundup

RoundupAmerica's Fertile Sportbike Ground

February 2005 By Mark Hoyer -

Roundup

RoundupEtc.

February 2005