The Combustion Compromise

TDC

Kevin Cameron

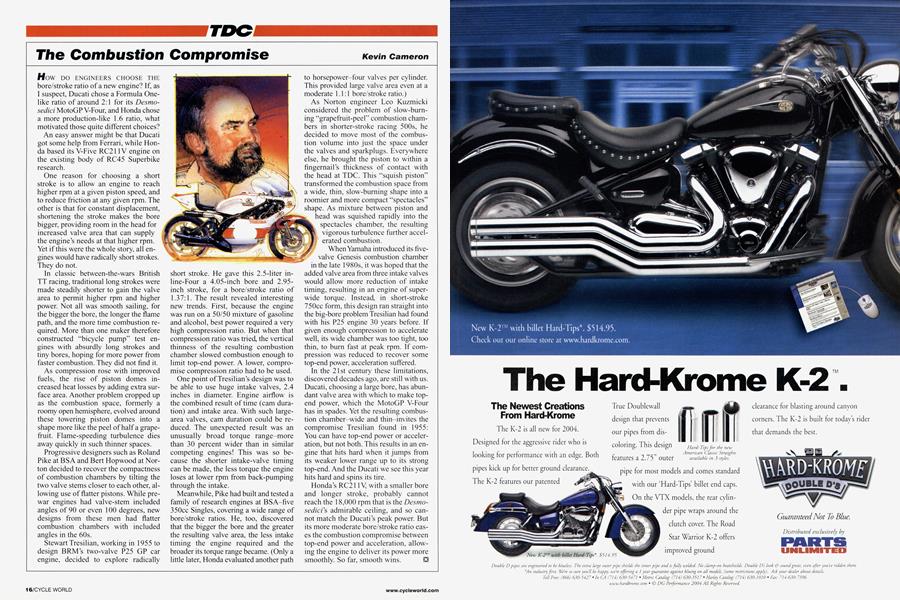

How DO ENGINEERS CHOOSE THE bore/stroke ratio of a new engine? If, as I suspect, Ducati chose a Formula One-like ratio of around 2:1 for its Desmosedici MotoGP V-Four, and Honda chose a more production-like 1.6 ratio, what motivated those quite different choices?

An easy answer might be that Ducati got some help from Ferrari, while Honda based its V-Five RC21IV engine on the existing body of RC45 Superbike research.

One reason for choosing a short stroke is to allow an engine to reach higher rpm at a given piston speed, and to reduce friction at any given rpm. The other is that for constant displacement, shortening the stroke makes the bore bigger, providing room in the head for increased valve area that can supply the engine’s needs at that higher rpm. Yet if this were the whole story, all engines would have radically short strokes. They do not.

In classic between-the-wars British TT racing, traditional long strokes were made steadily shorter to gain the valve area to permit higher rpm and higher power. Not all was smooth sailing, for the bigger the bore, the longer the flame path, and the more time combustion required. More than one maker therefore constructed “bicycle pump” test engines with absurdly long strokes and tiny bores, hoping for more power from faster combustion. They did not find it.

As compression rose with improved fuels, the rise of piston domes increased heat losses by adding extra surface area. Another problem cropped up as the combustion space, formerly a roomy open hemisphere, evolved around these towering piston domes into a shape more like the peel of half a grapefruit. Flame-speeding turbulence dies away quickly in such thinner spaces.

Progressive designers such as Roland Pike at BSA and Bert Hopwood at Norton decided to recover the compactness of combustion chambers by tilting the two valve stems closer to each other, allowing use of flatter pistons. While prewar engines had valve-stem included angles of 90 or even 100 degrees, new designs from these men had flatter combustion chambers with included angles in the 60s.

Stewart Tresilian, working in 1955 to design BRM’s two-valve P25 GP car engine, decided to explore radically

short stroke. He gave this 2.5-liter inline-Four a 4.05-inch bore and 2.95inch stroke, for a bore/stroke ratio of 1.37:1. The result revealed interesting new trends. First, because the engine was run on a 50/50 mixture of gasoline and alcohol, best power required a very high compression ratio. But when that compression ratio was tried, the vertical thinness of the resulting combustion chamber slowed combustion enough to limit top-end power. A lower, compromise compression ratio had to be used.

One point of Tresilian's design was to be able to use huge intake valves, 2.4 inches in diameter. Engine airflow is the combined result of time (cam dura tion) and intake area. With such largearea valves, cam duration could be re duced. The unexpected result was an unusually broad torque range-more than 30 percent wider than in similar competing engines! This was so be cause the shorter intake-valve timing can be made, the less torque the engine loses at lower rpm from back-pumping through the intake.

Meanwhile, Pike had built and tested a family of research engines at BSA-five 350cc Singles, covering a wide range of bore/stroke ratios. He, too, discovered that the bigger the bore and the greater the resulting valve area, the less intake timing the engine required and the broader its torque range became. (Only a little later, Honda evaluated another path

to horsepower-four valves per cylinder. This provided large valve area even at a moderate 1.1:1 bore/stroke ratio.)

As Norton engineer Leo Kuzmicki considered the problem of slow-burning “grapefruit-peel” combustion chambers in shorter-stroke racing 500s, he decided to move most of the combustion volume into just the space under the valves and sparkplugs. Everywhere else, he brought the piston to within a fingernail’s thickness of contact with the head at TDC. This “squish piston” transformed the combustion space from a wide, thin, slow-burning shape into a roomier and more compact “spectacles” shape. As mixture between piston and head was squished rapidly into the spectacles chamber, the resulting vigorous turbulence further accelerated combustion.

When Yamaha introduced its fivevalve Genesis combustion chamber in the late 1980s, it was hoped that the added valve area from three intake valves would allow more reduction of intake timing, resulting in an engine of superwide torque. Instead, in short-stroke 750cc form, this design ran straight into the big-bore problem Tresilian had found with his P25 engine 30 years before. If given enough compression to accelerate well, its wide chamber was too tight, too thin, to burn fast at peak rpm. If compression was reduced to recover some top-end power, acceleration suffered.

In the 21st century these limitations, discovered decades ago, are still with us. Ducati, choosing a large bore, has abundant valve area with which to make topend power, which the MotoGP V-Four has in spades. Yet the resulting combustion chamber-wide and thin-invites the compromise Tresilian found in 1955: You can have top-end power or acceleration, but not both. This results in an engine that hits hard when it jumps from its weaker lower range up to its strong top-end. And the Ducati we see this year hits hard and spins its tire.

Honda’s RC211V, with a smaller bore and longer stroke, probably cannot reach the 18,000 rpm that is the Desmosedici's admirable ceiling, and so cannot match the Ducati’s peak power. But its more moderate bore/stroke ratio eases the combustion compromise between top-end power and acceleration, allowing the engine to deliver its power more smoothly. So far, smooth wins. □q

View Full Issue

View Full Issue