Time to burn

TDC

Kevin Cameron

GETTING MAXIMUM POWER FROM COMbustion in a piston engine calls for correct phasing of two phenomena. One is the motion of the piston, rising on compression towards top dead center, stopping there, then starting downward on the power stroke. The other is the ignition, burning and rapid pressure rise of the fuel-air mixture trapped above that piston.

Dyno studies, performed with electronic pressure gauges tapped into combustion chambers, reveal that best power is given when peak combustion pressure occurs at about 15 degrees after top center. It is easy to see why this should be so. To obtain the highest possible peak pressure, it must occur while the gases are tightly confined, with the piston still near TDC. But to avoid time losses, it must also occur just as the piston begins significant downward movement. Piston movement near TDC is so slow that it can be regarded as essentially stopped for about 30 degrees. Thus, peak pressure occurring at 15 degrees ATDC combines these two requirements.

During compression, as the piston rises towards TDC, pressure in the mixture rises as the piston packs it into an ever-smaller space. At some point close to top dead center-typically 30-40 degrees before TDC in a four-stroke bike engine-a spark ignites the compressed mixture. After ignition, further pressure rise comes from two sources: compression by the still-rising piston, and heating of the mixture by the rapidly spreading combustion flame.

Normal combustion in piston engines is not an explosion-far from it. An explosion wave in a fuel-air mixture travels at thousands of feet per second, but normal combustion proceeds at a much slower 50-250 feet per second. It takes time-and many crank degrees-for combustion to consume the mixture. Once the flame begins to spread, the pressure rise generated by combustion proceeds at a rate of a few tens of pounds per square inch, per degree of crankshaft rotation. This rise spikes up to a very high peak as most of the mixture is consumed by the flame, then pressure falls rapidly as the piston begins its descent on the power stroke, expanding the charge as its last remnants burn. The rule of thumb is that full-throttle peak pressure in psi is roughly 100 times the compression ratio. On a time basis, the combustion event is approximately centered around TDC, from about 30-40 BTDC to an equal angle ATDC. On a pressure basis, combustion pressure is naturally heavily biased towards the after-TDC side.

As the piston descends, combustiongas pressure falls rapidly because of gas expansion-the space above the piston becomes bigger very quickly, but the amount of gas in it remains constant.

By the time the piston has moved through only half its stroke, 80 percent of the feasibly recoverable pressure energy in the burned gas has done its work on the piston; almost all the action occurs in the top half of the stroke. This is dandy, for it leaves the rest of the downstroke available for the exhaust process. In four-strokes, the exhaust válves open well before bottom center to allow combustion gases to leave the cylinder by their own pressure; otherwise the piston would have to do the work of forcing them out, and power would be lost in the process.

What if peak pressure comes too early or ,too late? As the spark is advanced (set to occur earlier), peak pressure is reached earlier, obliging the piston to hold this high pressure until the crank rotates enough to let the piston begin its descent. Nasty negative work is performed in compressing burning charge before TDC. Long confinement of the burning mixture causes knock and increases heat loss. As burned gases cool, they lose pressure, and less power is developed. The lost power shows up in the cooling system as overheating. Obviously, advancing timing beyond the best-power setting is silly.

Setting timing a little later than optimum has almost no ill effects. In fact, the recommended timing for production engines is often a bit retarded from the peak-power setting because this extends sparkplug life and also has a significant knock-reducing effect. More retard cuts power because peak pressure occurs after the piston has descended significantly, so peak pressure is reduced. The lost power goes out the exhaust as waste heat, cooking the exhaust valves and making the pipes glow.

Intuitively, you’d expect engines to need more ignition advance as they rev up. Because there’s less time for combustion at higher revs, this seems to make sense, but it isn’t so. In fact, as an engine revs up, the turbulence generated in its combustion chamber by the intake process also speeds up-boosting flame speed to keep timing requirement near-constant.

This is not to say that any one timing is perfect for all speeds. There are many variables that affect flame speed. For example, the better the cylinder is filled with fresh mixture, the faster the flame. Things that affect cylinder filling-like intake and exhaust tuning-may work for us at certain engine speeds, against us at others. This causes variation in flame speed that must be compensated by ignition timing changes.

Roughly, the more torque an engine is making, the less timing it needs, so the curve of best timing is like the inverse of the torque curve. Engines with nearly constant torque-four-strokes at low to moderate levels of tune-can therefore work happily with fixed timing. Those with mountainous torque curves-all two-strokes, and fourstrokes in the highest states of tune-do best with today’s so-called “mapped” ignitions. These are computer-controlled ignitions in which are stored the exactly correct ignition timings for all conditions of rpm and, often, throttle opening, as determined in dyno testing. Such ignitions boost power because they ensure that peak pressure comes always at the optimum point-despite the constantly changing variables. □

View Full Issue

View Full Issue

More From This Issue

-

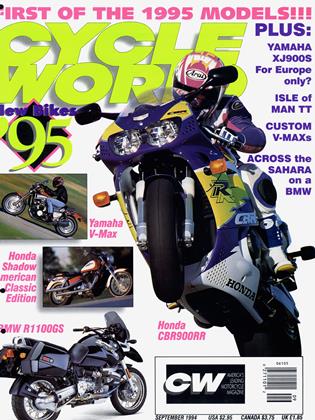

Up Front

Up FrontNotes From the Alps

September 1994 By David Edwards -

Leanings

LeaningsRiding Home

September 1994 By Peter Egan -

Letters

LettersLetters

September 1994 -

Roundup

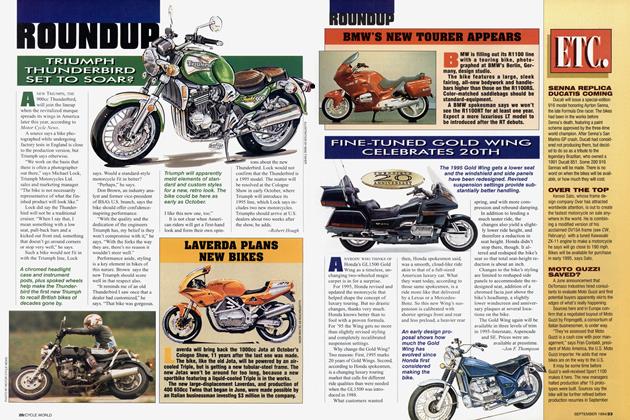

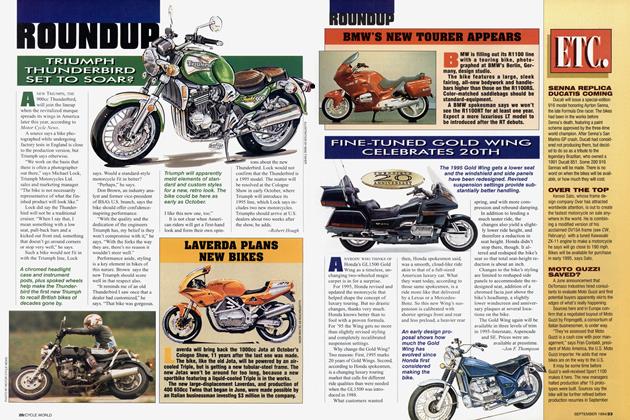

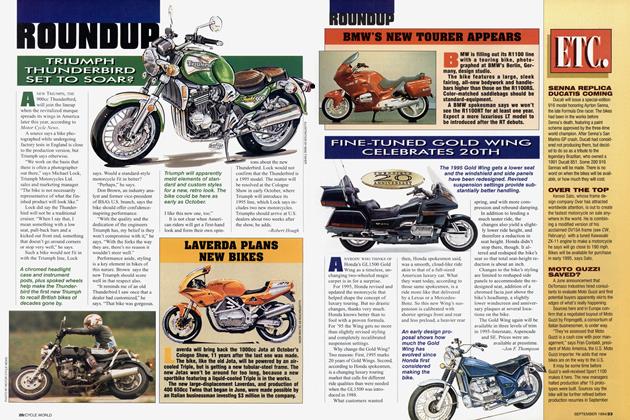

RoundupTriumph Thunderbird Set To Soar?

September 1994 By Robert Hough -

Roundup

RoundupLaverda Plans New Bikes

September 1994 -

Roundup

RoundupBmw's New Tourer Appears

September 1994