Engine architecture

TDC

Kevin Cameron

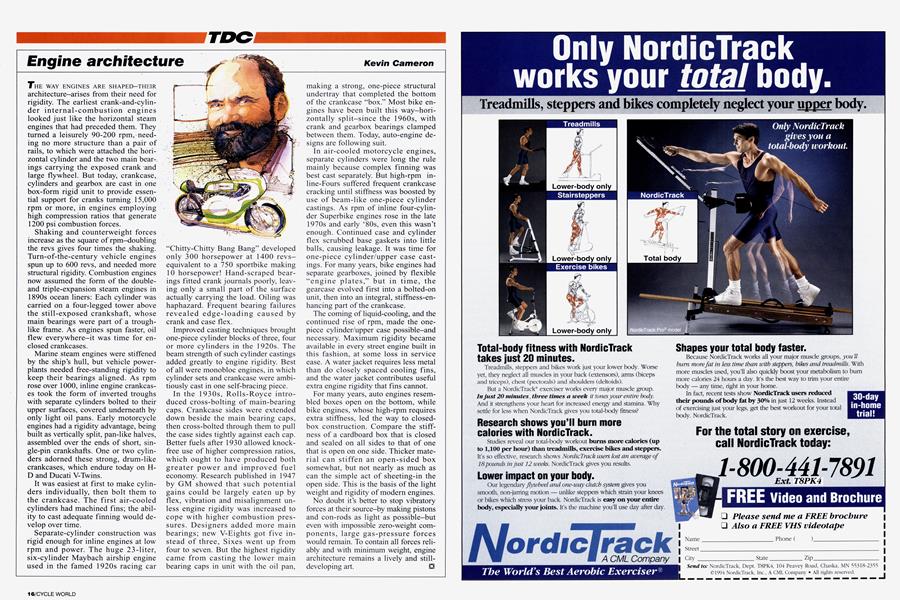

THE WAY ENGINES ARE SHAPED-THEIR architecture—arises from their need for rigidity. The earliest crank-and-cylinder internal-combustion engines looked just like the horizontal steam engines that had preceded them. They turned a leisurely 90-200 rpm, needing no more structure than a pair of rails, to which were attached the horizontal cylinder and the two main bearings carrying the exposed crank and large flywheel. But today, crankcase, cylinders and gearbox are cast in one box-form rigid unit to provide essential support for cranks turning 15,000 rpm or more, in engines employing high compression ratios that generate 1200 psi combustion forces.

Shaking and counterweight forces increase as the square of rpm-doubling the revs gives four times the shaking. Turn-of-the-century vehicle engines spun up to 600 revs, and needed more structural rigidity. Combustion engines now assumed the form of the doubleand triple-expansion steam engines in 1890s ocean liners: Each cylinder was carried on a four-legged tower above the still-exposed crankshaft, whose main bearings were part of a troughlike frame. As engines spun faster, oil flew everywhere-it was time for enclosed crankcases.

Marine steam engines were stiffened by the ship’s hull, but vehicle powerplants needed free-standing rigidity to keep their bearings aligned. As rpm rose over 1000, inline engine crankcases took the form of inverted troughs with separate cylinders bolted to their upper surfaces, covered underneath by only light oil pans. Early motorcycle engines had a rigidity advantage, being built as vertically split, pan-like halves, assembled over the ends of short, single-pin crankshafts. One or two cylinders adorned these strong, drum-like crankcases, which endure today on HD and Ducati V-Twins.

It was easiest at first to make cylinders individually, then bolt them to the crankcase. The first air-cooled cylinders had machined fins; the ability to cast adequate finning would develop over time.

Separate-cylinder construction was rigid enough for inline engines at low rpm and power. The huge 23-liter, six-cylinder Maybach airship engine used in the famed 1920s racing car “Chitty-Chitty Bang Bang” developed only 300 horsepower at 1400 revsequivalent to a 750 sportbike making 10 horsepower! Hand-scraped bearings fitted crank journals poorly, leaving only a small part of the surface actually carrying the load. Oiling was haphazard. Frequent bearing failures revealed edge-loading caused by crank and case flex.

Improved casting techniques brought one-piece cylinder blocks of three, four or more cylinders in the 1920s. The beam strength of such cylinder castings added greatly to engine rigidity. Best of all were monobloc engines, in which cylinder sets and crankcase were ambitiously cast in one self-bracing piece.

In the 1930s, Rolls-Royce introduced cross-bolting of main-bearing caps. Crankcase sides were extended down beside the main bearing caps, then cross-bolted through them to pull the case sides tightly against each cap. Better fuels after 1930 allowed knockfree use of higher compression ratios, which ought to have produced both greater power and improved fuel economy. Research published in 1947 by GM showed that such potential gains could be largely eaten up by flex, vibration and misalignment unless engine rigidity was increased to cope with higher combustion pressures. Designers added more main bearings; new V-Eights got five instead of three, Sixes went up from four to seven. But the highest rigidity came from casting the lower main bearing caps in unit with the oil pan, making a strong, one-piece structural undertray that completed the bottom of the crankcase “box.” Most bike engines have been built this way-horizontally split-since the 1960s, with crank and gearbox bearings clamped between them. Today, auto-engine designs are following suit.

In air-cooled motorcycle engines, separate cylinders were long the rule mainly because complex finning was best cast separately. But high-rpm inline-Fours suffered frequent crankcase cracking until stiffness was boosted by use of beam-like one-piece cylinder castings. As rpm of inline four-cylinder Superbike engines rose in the late 1970s and early ‘80s, even this wasn’t enough. Continued case and cylinder flex scrubbed base gaskets into little balls, causing leakage. It was time for one-piece cylinder/upper case castings. For many years, bike engines had separate gearboxes, joined by flexible “engine plates,” but in time, the gearcase evolved first into a bolted-on unit, then into an integral, stiffness-enhancing part of the crankcase.

The coming of liquid-cooling, and the continued rise of rpm, made the onepiece cylinder/upper case possible-and necessary. Maximum rigidity became available in every street engine built in this fashion, at some loss in service ease. A water jacket requires less metal than do closely spaced cooling fins, and the water jacket contributes useful extra engine rigidity that fins cannot.

For many years, auto engines resembled boxes open on the bottom, while bike engines, whose high-rpm requires extra stiffness, led the way to closedbox construction. Compare the stiffness of a cardboard box that is closed and sealed on all sides to that of one that is open on one side. Thicker material can stiffen an open-sided box somewhat, but not nearly as much as can the simple act of sheeting-in the open side. This is the basis of the light weight and rigidity of modern engines.

No doubt it’s better to stop vibratory forces at their source-by making pistons and con-rods as light as possible-but even with impossible zero-weight components, large gas-pressure forces would remain. To contain all forces reliably and with minimum weight, engine architecture remains a lively and stilldeveloping art.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontIncident On the Angeles Crest

November 1994 By David Edwards -

Leanings

LeaningsGs-Ing It

November 1994 By Peter Egan -

Letters

LettersLetters

November 1994 -

Roundup

RoundupAprilia Reveals Trick 250

November 1994 By Robert Hough -

Roundup

RoundupSuzuki Gets Savage For 1995

November 1994 -

Roundup

RoundupNew Gsx-R750 A Year Away

November 1994 By Robert Hough