Apples & crocodiles

TDC

Kevin Cameron

PISTONS FOUND AN EASY LIFE WHEN they first came into this world. Idling along at 350 rpm in horizontal steam engines, their peak back-and-forth acceleration was a few hundred times the acceleration of gravity, their operating temperature close to that of boiling water.

Even for that era’s most highly stressed “pistons”-cannonballs-the acceleration of being fired averaged less than 2000 g, not much by today’s standards. Cast iron, a metal whose porous, oil-absorbing structure made it a durable friction surface, was comfortable in both roles.

The earliest internal-combustion engines were modeled on steam engines, so they too had iron pistons. Cooling was necessary to keep oil from vaporizing and closely fitted parts from expanding enough to seize.

In the 1890s, French builders de Dion and Bouton found that IC engines could be run at the dizzying speed of 3600 rpm. This broke down the barriers to the lower weight per horsepower necessary to power vehicles. Because the strokes of these much smaller engines were short, peak piston acceleration remained at a tiddly 450 g. Many thousands of these engines were sold.

Humans are greedy, so in short order racing car and motorcycle engines were hurling their iron pistons through greatly increased strokes at similar rpm. Piston acceleration stress rose in more or less direct proportion to stroke-to levels that broke parts. They broke from a combination of three effects. First, ordinary cast iron is brittle-the graphitefilled cavities that riddle it are like dots just waiting to be connected by the lines of applied stress. Second, because iron is a poor heat conductor, the part of the piston farthest from the cooled cylinder wall-the center of its crown-became very hot. Third, the high and constantly reversing accelerations of pistons quickly fatigued the heat-softened metal.

The second point had another effect. The larger a piston’s diameter was made, the farther heat had to travel from the center of the crown to the wall. This increased resistance to heat flow made bigger pistons run hotter and fail sooner. Because smaller-bore pistons survived better, long-stroke engines became the choice of designers.

To keep piston inertia loads from breaking connecting rods, pistons were made as light as possible. A peak piston acceleration of 3000 g at top dead center, applied to a 1-pound piston, translates to a 3000-pound upward yank on the conrod, crankshaft and crank bearings. Cutting piston weight in half by clever foundry work cut that yank in half as well, a clear mechanical benefit. But lighter pistons were weaker, and thinner piston crowns conducted heat even less well than thicker, heavier ones. Designers were crowded into a tiny safety zone by stress, temperature and weight. And there they remain to this day.

The Bessemer Process (1860) advanced railroads from cast iron to steel, a stronger, tougher and more fatigue-resistant metal. Steel also found its way into car and bike racing pistons, where its properties permitted 10 percent higher crank speeds. This brought a fresh problem: Steel cannot absorb lubricant as iron does, so piston life was shortened by rapid wear. Remember the old phrase “wears like iron?”

During WWI, young W.O. Bentley saw that aluminum conducts heat so wonderfully that it could ease the pinch of stress/temperature/weight that held piston designers prisoner. Iron pistons were by then so artfully made that an equivalent-sized aluminum piston was no lighter, but the superior heat conduction of aluminum pulled the temperature of pistons down so much that new possibilities beckoned.

Think of a hot iron piston, rising on its compression stroke. Swirling above it is a potent mixture of gasoline and air, heating rapidly from contact with the hot metal. Even if the piston isn’t hot enough to ignite the mixture before the spark does (pre-ignition), it is hot enough to radically change the chemistry of that mixture. As the normal flame front compresses the last bits of the charge ahead of it, they explode instead of burning, generating violent shocks moving at the local speed of sound. This is detonation, a constant problem in the days of iron pistons.

Bentley’s new aluminum pistons ran so much cooler that he and his engineers were able to raise compression ratio again and again, safely and without provoking detonating combustion. Thus, unlikely as it seems, cooler pistons translated to increased engine torque.

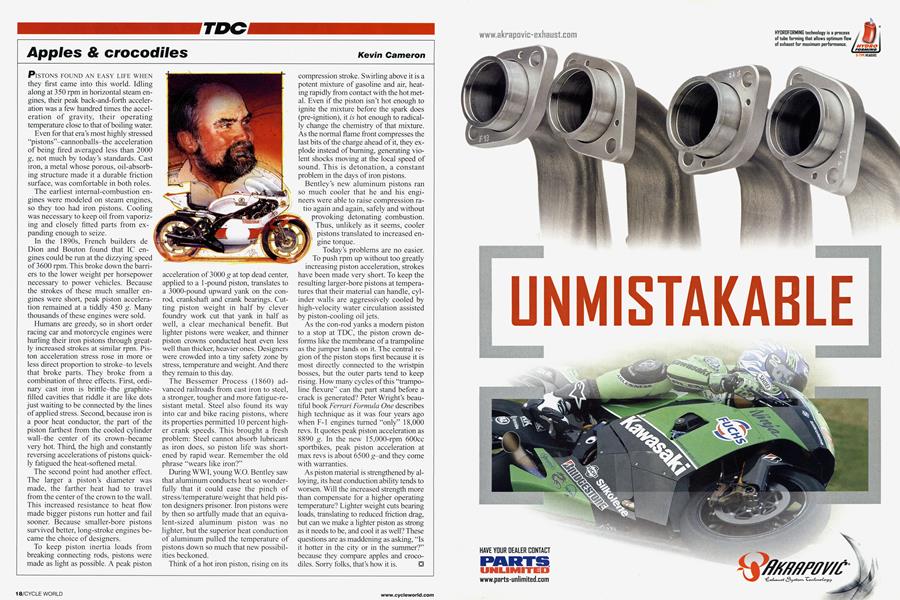

Today’s problems are no easier. To push rpm up without too greatly increasing piston acceleration, strokes have been made very short. To keep the resulting larger-bore pistons at temperatures that their material can handle, cylinder walls are aggressively cooled by high-velocity water circulation assisted by piston-cooling oil jets.

As the con-rod yanks a modern piston to a stop at TDC, the piston crown deforms like the membrane of a trampoline as the jumper lands on it. The central region of the piston stops first because it is most directly connected to the wristpin bosses, but the outer parts tend to keep rising. How many cycles of this “trampoline flexure” can the part stand before a crack is generated? Peter Wright’s beautiful book Ferrari Formula One describes high technique as it was four years ago when F-l engines turned “only” 18,000 revs. It quotes peak piston acceleration as 8890 g. In the new 15,000-rpm 600cc sportbikes, peak piston acceleration at max revs is about 6500 g-and they come with warranties.

As piston material is strengthened by alloying, its heat conduction ability tends to worsen. Will the increased strength more than compensate for a higher operating temperature? Lighter weight cuts bearing loads, translating to reduced friction drag, but can we make a lighter piston as strong as it needs to be, and cool it as well? These questions are as maddening as asking, “Is it hotter in the city or in the summer?” because they compare apples and crocodiles. Sorry folks, that’s how it is.