SERVICE

Paul Dean

A little piece of Pi

What is the formula for calculating engine displacement? My 900 Ninja has a 72.5mm bore and 55mm stroke, and that equals 3987.5. I divide that by 4 (pistons) and I get 996.875, but my Ninja displaces 908.2cc. I also want to convert the cubic centimeter numbers to cubic inches for measuring the displacement of Harleys. How do I do all this?

Peter Bonetti Tampa, Florida

I don’t know how you came up with your method of calculating displacement, but it s not even remotely close. The correct formula is fairly simple, but you’ll probably find it easier to understand if I explain its separate elements before giving you the complete formula. First, you calculate the surface area of the bore by multiplying the radius of the cylinder (which is one-half of the bore diameter) by itself then multiplying that number by Pi (3.14159). You then multiply that result by the stroke, which gives you the volume of one cylinder. Multiply that number by the number of cylinders, and you have the displacement. The formula, then, is: Pi x r2 x stroke x no. of cyls.

When calculating displacement in the metric system, there is one more step. The bore-and-stroke dimensions are measured in millimeters, but displacement is expressed in cubic centimeters. This requires a simple conversion either at the beginning or at the end. You can take that extra step before starting

your displacement calculation by converting millimeters to centimeters (simply divide millimeters by 10); or you can do it at the end by converting cubic millimeters to cubic centimeters (multiply your answer by .001). When working with the SAE (inch) system, no conversion is necessary.

Now let ’s use your Ninja ’s engine as an example. Determine the cylinder’s radius by dividing the bore in half (72.5 + 2 = 36.25). Multiply the result first by itself then by Pi (36.25 x 36.25 x 3.14159 = 4128.245). Multiply that by

the stroke, then by the number of cylinders (4128.245 x 55 x 4 = 908213.9). Multiply by .001 and you get 908.214cc.

To convert cubic centimeters into cubic inches, you multiply the cc by .06102 (in the case of your Ninja, that would be 908.214 x .06102 = 55.419 cubic inches). To convert the other way, multiply the cubic inches by 16.387 to get cubic centimeters (55.419 x 16.387 = 908.151). That small difference in displacement (908.214 vs. 908.151) is the result of rounding off the calculations to just three decimal places.

Cylinder inclinations

A bunch of us on an EX500 mailing list need some help to settle a dispute: Why do sportbike cylinders angle forward? There are currently two camps on this subject: Those who feel it is a packaging issue-/, e., to get the cylinders closer to the front wheel to help minimize overall wheelbase; and those who feel it is to provide a straighter path to the intakes, thus maximizing intake velocity. Can you give us your thoughts on this topic? Chuck Calvert

West Hartford, Connecticut

In a way, both of your “camps ” are correct. With its Genesis engines in the 1980s, Yamaha began the current trend of canting the cylinders of inlineFours forward in order to permit straighter intake tracts.

Other manufacturers soon followed suit, but packaging also has become a factor in this style of engine design. For-

ward-inclined cylinders lower the center of gravity, thus bringing some of the heavy top-end components closer to the bike’s roll center. Their inclination also places more weight on the front wheel, which helps make the steering more predictable and precise, especially at racing speeds. And tilting the cylinders forward provides more room behind them for “stacking’’ the transmission shafts vertically rather than aligning them horizontally. This, in turn, allows a longer swingarm without also I . having to lengthen the wheelbase. What’s more, the main benefit of straighter intake tracts is not necessarily greater intake velocity; it’s improved intake efficiency. As airflow guru

Jerry Branch is fond of saying, “Air does not like to turn corners; it prefers to travel in a straight line.’’ Making air change direction causes turbulence and other disturbances in the flow that reduce the maximum volume of mixture that can be drawn into the cylinders, especially at higher rpm. This is why, all other factors being equal, an engine with a straight intake airflow usually will make more peak power than one with curved intakes.

No gas, no go

I have a 1995 Kawasaki ZX-6R. I ran out of gas while on the reserve tank and the bike has not run since. Sometimes it will start and run for a minute or two, but after that it dies. After talking to the local shop, I cleaned out the fuel system and replaced the sparkplugs. Neither of these remedies has helped at all. Please advise. Let ’s think logically here. The engine performed properly before it ran out of gas, so it s only rational to believe that the problem is fuel-system-related, not electrical or mechanical. That would rule out the sparkplugs.

Wesley Gerbick Columbus, Ohio

Usually, the worst thing that occurs when a bike runs out of gas is that any contamination that might have been sitting harmlessly on the very bottom of the fuel tank gets drawn into the fuel lines as the last bits of gas drain into the system. When this happens, any filters or screens in the system can become clogged, either partially or completely blocking the flow of fuel. Locating the blockage is a matter of troubleshooting the fuel system line by line until you find the point at which the flow stops.

When you stated that you “cleaned out the fuel system,’’ you weren’t specific; I suspect that you didn’t go through the entire system and all of its individual components, several of which are prime candidates for blockage. The ZX-6R has two separate feed lines leading to the fuel tap from fittings threaded into the gas tank; one is for the On position, the other for Reserve, and each line has a dedicated filter screen atop its fitting inside the tank. You need to disconnect the lines at the fuel tap, one by one, and determine if gas flows freely from both. If it does not, the screen for that line is blocked—although the Reserve line would be the most likely culprit, since it was the one in use when you ran out of gas.

There also is a filter just upstream of the ZX-6R ’s electric fuel pump; if it is clogged, the pump won’t be able to draw fuel from the tank and deliver it to the carburetors. Disconnect the filter from the pump and determine if fuel flows freely from the tank and through the filter simply due to gravity. If it doesn’t, replace the filter. It’s also possible that the fuel pump itself is malfunctioning as the result of your running out of gas. To check it, attach a short piece of fuel line to the pump ’s outlet fitting and put the other end of that line into a small bottle or can. If you then turn on the ignition and thumb the starter button, fuel should flow from the pump. The problem is located somewhere in your Kawi s fuel system; if you track it down logically, you ’ll eventually find it.

Slide Job

I have a new problem with my beloved old bike, a 1979 Yamaha XT500. Aside from a new 32mm Mikuni carb, it’s stock, including the airbox and pipe, and it runs fairly well. The problem is that it pings loudly at low rpm under load in fourth and fifth gears from 3000 to 3800 rpm. From 2000 to 3000 rpm, it pulls cleanly in these gears at about one-quarter throttle; but without any change in throttle position, it will begin pinging as it reaches 3000, then stops at around 3800. If I open the throttle to about the one-half point, the pinging stops. The carb settings are 200 main jet, 40 pilot jet, 2.5 throttle slide, 2.0 air jet, P-4 needle jet, needle on second notch from richest, air screw out VA turns. The advance mechanism seems to work properly, and I use premium fuel. Any help would be appreciated. Steve Murray Posted on America Online

Based on the symptoms and carburetor specs you have provided, it’s my guess that your XT500 needs a 2.0 throttle slide, which is the next-richest option. The slide is the primary mixture-control mechanism when the throttle is between about one-

eighth and one-quarter open, and its number (2.0, 2.5, 3.0, etc.) is a measure of the height of the cutaway on its inlet side; the higher the cut-

away, the leaner the mixture. You might be able to lessen the pinging somewhat by slightly richening the idle mixture and

raising the jet needle to its highest position, but that would likely have negative effects on idle stability and engine performance between one-quarter and three-quarter throttle. The only rational solution is to install a richer slide.

Unless your nickname is “Lucky,” you probably won’t find the required slide at a dealership. If that’s the case, call the people at Mikuni American (818/8851242) and they will tell you how and where to obtain the part you need.

FEEDBACK LOOP

I just re-read your response to Damian Montleone (“Sit up and beg,” December, 2003) about installing handlebar risers on sportbikes. After trying to find risers for my Suzuki SV650S, I came upon a website for a company that makes a product called Convertibars (www.convertibars.com). While these bars will not fit every sportbike, the list of the models they will fit is quite impressive, involving almost anything that mounts the bars to the fork tubes like clip-ons. I do not work for this company in any capacity, but they are located near my home and did install a set of Convertibars on my SV. Bruce Brekke

Posted on America Online

Although I was aware of Convertibars’ existence when I wrote that reply, I didn’t know much about them or the wide range of bikes they supposedly will fit. Since then, I’ve become more informed about this product, and we even have obtained a set designed to fit an ’03 Suzuki GSX-R1000. We have installed them and will publish a product evaluation in a future issue. But thanks for the input anyway; I appreciate you keeping me on my toes.

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631-0651; 3) email it to CW1Dean@aol.com, or 4) log onto www.cycleworld.com, click on the “Letters to the Editor” button and enter your question. Don’t write a 10-page essay, but if you’re looking for help in solving a problem, do include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.

The seal’s the deal

I have a 1996 Kawasaki Vulcan 1500A with 25,000 miles. At times, it smokes heavily when idling and continues to do so until the engine is revved for a few seconds. This only happens occasionally; most of the time there is no apparent smoke. I first noticed this about a year ago after riding several miles on the interstate. The bike sat for a few minutes while I checked into a motel, and it smoked heavily when restarted. The next day it ran fine, with no smoking. I would think that if the rings were worn, the engine would smoke all the time, not just every once in a while. The bike does not seem to use an inordinate amount of oil; I add about a third of a quart every 500 miles, which is no more than it used when I bought the bike three years ago with 6000 miles on the odometer. Any idea what might be causing the smoking? Sam Brantingham

Martinsville, Virginia

I suspect that your Kawasaki has at least one leaky valve seal. Like most engines, the Vulcan 1500 uses a small seal atop each valve guide to prevent oil from seeping down along the valve stem and into the combustion chamber. If the seal is faulty, enough oil can find its way into the combustion process to produce noticeable smoking from the exhaust.

This is more of an issue on some engines than others, depending upon the layout of the cylinders and the configuration of the cylinder head in the area around the valves. On your Vulcan, the exhaust valves are located at the extremes of the cylinder heads-the front exhausts at the leading edge of the front head, the rears at the trailing edge of the rear head. Which means all four of this V-Twin ’s exhaust valves are located at the lowest part of their respective camboxes, where oil is most likely to accumulate in any quantity. When you shut the engine off and it has a slightly leaky valve seal, just enough of that accumulated oil can seep past the seal and get into the combustion chamber to cause a bit of smoking when the engine is restarted. Oil is thinner when it’s hot, so it can find its way past a leaky seal more easily than when it ’s cold.

In all probability, the leaky seal allows some oil to seep into the combustion chamber when the engine is running, but the amount is too small to produce any noticeable smoking or affect the oil consumption. When the hot engine is shut off for a while, however, enough oil can leak into the cylinders to cause smoking when it is restarted.

If the smoking only occurs every once in a while and only for a very short period, you may simply want to live with it. The seals themselves are inexpensive, but replacing them is a major job that requires removal of the engine. Matter of fact, you can’t even get one of the valve covers off a 1500 Vulcan engine while it is still in the frame. □

View Full Issue

View Full Issue

More From This Issue

-

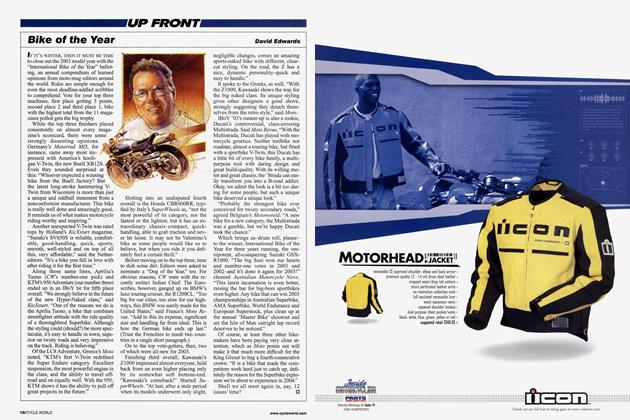

Up Front

Up FrontBike of the Year

February 2004 By David Edwards -

Leanings

LeaningsLost Summers

February 2004 By Peter Egan -

TDC

TDCSuperbike Situations

February 2004 By Kevin Cameron -

Departments

DepartmentsHotshots

February 2004 -

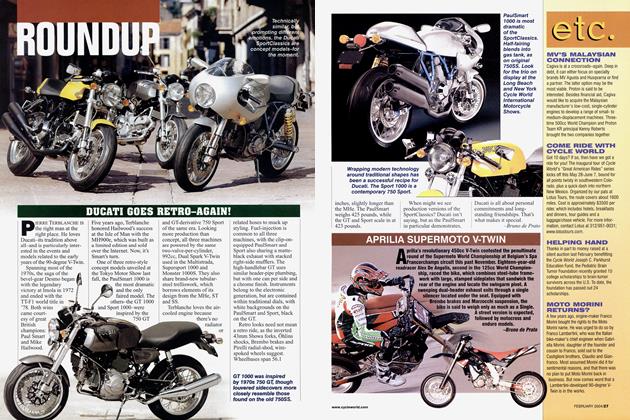

Roundup

RoundupDucati Goes Retro-Again!

February 2004 By Bruno De Prato -

Roundup

RoundupAprilia Supermoto V-Twin

February 2004 By Bruno De Prato