SERVICE

Paul Dean

Hot-oil heartaches

I recently installed a digital temperature gauge on my ’99 Harley-Davidson Twin Cam Ultra Classic, which has 64,000 miles on it. The gauge is from Harley’s Parts & Accessories catalog, and it’s a replacement dipstick that has an LCD temperature readout in the cap. When the bike is traveling 80 mph in 90-degree weather, the gauge reads 256 degrees. I don’t know whether that’s good or bad, because I’ve been unable to find any information that tells me the oil-temperature parameters for my bike. Can you help?

Gary Shelton Posted on www.cycleworld.com

When asked, Harley-Davidson will supply information regarding the acceptable range of oil temperatures for Twin Cam engines, but that data was developed by The Motor Company using only its own H-D 360 motor oil. As far as any other oils are concerned, the company claims not to know anything about their performance, including operating temperatures. You didn’t mention which brand of lubricant you use in your Ultra, but the following information should apply regardless-unless, of course, you 're buying 59<t-aquart used oil that was filtered through a sweat sock.

According to Harley, the oil ideally should run in the 215-to-225-degree range, although temperatures as high as 240 degrees are not unusual. In moresevere operating conditions, temperatures as high as 285 degrees are possible, although the factory considers them acceptable only for short periods of time. Temperatures of 300 degrees and higher are in the danger zone and should be avoided.

Given those parameters, your Ultra's 256-degree oil temperatures seem well within acceptable limits. Remember, you 're talking about a big-inch, aircooled machine motoring down the road on a very hot day at 80 mph, which is somewhere between the engine 's peak-torque and peak-horsepower rpm (where it generates more heat than it would at lower revs), poking a big hole in the wind with a fairing designed more for rider protection than for aerodynamics. Plus, the Ultra's fairing lowers also obstruct a bit of the airflow that might otherwise reach the engine.

Despite all that, 1 wouldn't lose a lot of sleep over the Ultra’s oil temps if I were you. But if you just can’t help worrying, you can always install an oil cooler. Harley makes an excellent, thermostatically controlled cooler (Part #62868-99) that will bolt right up to your FLHTCU.

What the fork is that noise?

I’m at my wit’s end trying to track down a clicking noise in the front of my 1998 Kawasaki ZX-9R. When I rock the bike over onto its sidestand, a metallic “click” comes from somewhere at the front. 1 can even feel it through the handlebars. I also hear the noise when cornering at a rapid rate, and 1 can hear and feel it when accelerating quickly. My dealer checked the bike over and tightened anything he thought could be responsible, including the steering to no avail. I had another mechanic look at it, but he couldn’t find any problem, either, though he did say that the noise seemed to be coming from the bottom of the left fork leg. I’ve tried removing the fairing and both front brake calipers, but the noise was still there. Any suggestions before I lose my mind? Julien Goderis Posted on www.cycleworld.com

Without being able to hear the noise myself, I can only guess, but I would wager that it is coming from inside the left fork leg. There may be something loose in the damper assembly, or perhaps the bolt securing the damper rod to the bottom of the fork leg has backed out. That would allow the bolt head to bang into the bottom of the leg when the fork tops out, which occurs when you flop the bike over onto the stand or accelerate hard. You and your mechanics seem to have eliminated everything , so one of you needs to tear into the fork leg.

Getting the final word in

Just wondering: Why, with the availability of clean, relatively maintenance-free kevlar belts, do motorcycle manufacturers still use chains as the final-drive to the rear wheel on street motorcycles that will never, ever be used on a racetrack?

Andy McLain Carol Stream, Illinois

A couple of reasons: One is that a belt is much wider than a chain of equivalent strength rating. Designers and engineers spend enormous amounts of time trying to develop engines and chassis that are as narrow as possible, and the use of a belt final drive would invariably result in some unfavorable compromises, such as wider motorcycles, narrower rear tires or both.

Furthermore, gearing changes are very inexpensive propositions with conventional sprockets, which are cheap and readily available, whereas beltdrive pulleys are much more expensive and available only in extremely limited choices of gear ratios. But you can buy countershaft and rear-wheel chain sprockets in just about any tooth count to fit just about any motorcycle. Belts make for a superb final-drive medium, but they are not without their own set of compromises.

Liquid-cooling fan

I have a question about liquid-cooled motorcycles. When I pull into my driveway after having ridden in slower traffic, the fan comes on to help cool the engine, which is what it is supposed to do. But should I let the engine idle until the fan does its job and shuts off by itself (usually a minute or two) or should I simply turn off the engine upon arrival? Is there a best answer for the longevity of the engine? For the record, I have four liquid-cooled motorcycles: ’94 Yamaha V-Max, ’96 BMW Kl 100RS, ’99 Ducati 996 and ’01 Triumph Speed Triple. Yes, I love my wife, too!

Steve Reinke Springboro, Ohio

You d better love her; she lets you have all those great motorcycles! But don’t worry about whether or not you should keep the fan running on any of those bikes when you stop its engine; either way, there are no engine-reliability issues at stake.

The coolant in an engine that has just been shut off immediately starts getting hotter than it normally would simply because it is stranded in the still-hot engine rather than passing through as it does when the engine is running. As the temperature of the coolant inside the engine increases, the temperature of the coolant in the radiator, which is exposed to the much cooler atmosphere, decreases. Liquids are less dense when hot than when cool, which causes hot coolant to rise and cool coolant to drop. That’s a process called convection, and it allows the hotter coolant to rise and flow slowly into the top of the radiator while the cooler coolant drops and makes its way out of the bottom of the

radiator and into the engine. So, even though the waterpump is not turning, the coolant slowly circulates through the engine and radiator until the temperature differential equalizes.

Obviously, the coolant temperature will drop more quickly if you leave the fan on than if you turn it off, but the impact on the engine in either case is not significantly different. Besides, the coolant in the engine can't get any hotter than the parts that heat it, and the source of that heat-combustion-has ceased.

My advice: Go take your wife for a

ride and stop worrying about the best way to shut off the engine.

Yellow speedo thingo

From some of the letters you’ve answered in Sendee, I’ve gathered that you’re a big fan of Honda VFRs. So am I. Currently, I have two: One is a ’96 750 daily rider that’s almost bone-stock, the other is a ’98 800 with a Staintune pipe and a complete front end brakes and all, salvaged from a 2000 GSX-R750 that got rear-ended. I’ve raised the final-drive gearing on the 750 nearly 10 percent so it cruises the freeways at a more relaxed rpm, but that has thrown my speedometer oft' an equivalent amount. Do you know of anyone who recalibrates motorcycle speedometers? I’ve done a lot of investigation around here and haven’t come up with anything.

Earl Plummer Rochester, New York

I’ve received quite a few letters inquiring about speedometer recalibration, and until now, I 've had no solutions to offer. The speedometers on practically all later-model bikes, particularly the electronic types on most sport models, are sealed units, and no parts are available for them anyway. But I’ve just learned of an Australian company, Black Robotics, that makes a product just for this purpose called The Yellow Box. It’s an electronic device that splices into the speedometer’s circuitry between the sending unit and the speedo itself, and it allows you to adjust the incoming signal to compensate for error.

FEEDBACK LOOP

In reference to your response to David Caulfield (“You never write anymore”) in the January issue: While you are correct in your assessment of the problem, H-D Big Twin riders should be aware of a special tool that can be used to hone the cylinder base by handlapping (works for Sportsters, too). It will remove any high spots and effectively ensure a uniform gasket seal, thereby preventing gasket blowouts. While the tops of Evo engine cases generally are found to be “true,” this is not always so with the cylinder bases. Uniformity can be achieved (especially on aftermarket cylinders) by using the Trock Evo Cylinder Base Lapping Ring. Better motorcycle performance shops are familiar with this process, but enterprising backyard mechanics can order the tool on the internet for $89.95 at www.cyborgcycles.com. Art Saracino Carle Place, New York

I know nothing about the quality or effectiveness of this product, but I do intend to acquire one for evaluation. I learned about it from a few different readers who have tried it, and they all gave it excellent reviews. If you log onto Black’s website (www.blackrobotics.com), you can learn more about The Yellow Box and even order one if you wish. But caveat emptor/ I’m informing you only of this product’s existence, not its performance.

Ferrous Bueller

My 2000 Buell Cyclone with 7200 miles on the odometer recently began making more noise than usual. After changing the oil, I followed a tip my late father once taught me and cut apart the old oil filter to inspect it. I found quite a few small metal filings down in the folds of the element, and when I poked a magnet in there, most of the debris stuck to it. The bike runs just fine and doesn’t smoke, but the noise is getting louder. Any idea what could be wrong? 1 hate to take it to my local dealer because, well, I hate my local dealer!

Scott Fraser Winter Park, Florida

If you want to minimize the repair bill, stop riding your Buell right now. The engine has either broken the roller on one of its hydraulic lifters or is in the process of fragging a connecting-rod bearing. The fact that debris stuck to the magnet means it’s ferrous (iron or steel), and those two components are the most likely sources. Most everything else that could cause a large quantity of metal filings to accumulate in the filter is made either of aluminum or bronze, which would not be attracted by the magnet.

You need to stop riding the bike to reduce the likelihood of even more extensive damage. When a rod bearing goes bad, ground-up particles of the bearing material circulate throughout the engine via the oiling system. In a plain-bearing engine, the damage those particles can cause usually is pretty limited, because the bearings are made of metals that are softer than most of the components they might come into contact with. But when a rod bearing breaks apart in a rollerbearing engine-such as in H-D Big Twins and Sportsters-the roller fragments can wreak havoc on the rest of the engine because they’re made of hardened steel that scores and gouges. Same goes for the lifter rollers, which also are made of hardened steel. You 've been riding the bike with this condition for a while, so even if the problem turns out to be only a lifter roller, you still should tear down the engine to determine if the steel debris has damaged anything else.

Watts up?

I would like to obtain information about calculating electrical loads. I’m interested in adding some electrical accessories to my bike, such as driving lights, heated clothing, etc. While it is fairly easy to add up the load created by the lights, since their wattage usually is printed right on the bulbs, I don’t know how to estimate the other loads. Also, the shop manual lists maximum alternator output, but that peak occurs at an rpm that is higher than I normally ride. So, how do I figure the load, and what does the alternator output vs. engine rpm curve typically look like? My specific interest is for a ’99 Yamaha YZF-R6, an ’89 Kawasaki EX250 and a ’94 BMW K75S, but some general guidelines would be helpful.

David W. Funk Pleasanton, California

As far as what the alternator-output curx’e looks like for any of those bikes, I have no idea. I’ve never plotted such a thing myself, and I don’t recall ever seeing one in any manufacturer’s technical material. But I can help you determine how much current draw any given alternator can handle.

Most electrical accessories have their wattage requirements posted somewhere, either on the devices themselves or in the documentation that accompanies them. Adding up those values will give you a pretty good idea of the current draw they would require, but that’s only part of the problem. Occasionally, you 'll encounter an electrical accessory that does not have its wattage listed anywhere; and, as you acknowledge, the alternator output ratings are only meaningful if the engine is revved at or above the peak-output rpm, which is not reflective of realworld riding speeds. So, rather than trying to calculate the current draw of extra accessories, I prefer to actually measure it.

Although electrical accessories are rated in watts, we ’re going to take our measurements in amperes. Just so you ’ll understand the relationship between the two, wattage is calculated by multiplying voltage times amperes. If for example, an accessory is rated at 20 watts, you merely divide 20 by 12 (the voltage) and get 1.67, which is that accessory ’s amperage.

To conduct the test, connect all the accessories you intend to use, start the engine and, as soon as it is warm enough, let it idle, then disconnect the negative battery cable. Now connect an ammeter that has at least a 10-ampere capacity between the battery and the cable, attaching the positive lead of the meter to the ground post of the battery and the negative lead of the meter to the ground cable. Rev the engine to the approximate rpm at which you would spend most of your time riding and observe the ammeter: It should indicate a charge of at least a few amps. Now, while holding the rpm at that same level, turn the accessories on one by one and observe each one s effect on the ammeter reading. If, by the time you get all the accessories operational, the ammeter still is in the positive side of the scale-ideally, by at least 1 ampere-you should have sufficient alternator power to keep the battery charged under normal riding conditions.

Recall Roster

NHTSA Recall NO.01V294 Kawasaki ZRX1200 Model year: 2001 Number of units involved: 3100 Problem: On certain motorcycles, a section of the wiring harness located above the headlight is routed incorrectly. As a result, turning the handlebar can cause abrasion of the wire harness sheath and wiring insulation, leading to malfunction of the turnsignals, instrument lights or indicator lights.

Remedy: Dealers will reroute the wiring harness and examine the harness and clamp for any signs of damage. Damaged clamps or wires will be repaired or replaced as appropriate. Owners who do not receive the free remedy within a reasonable time should contact Kawasaki at 949/770-0400.

Got a mechanical or technical problem with your beloved ride? Can’t seem to find reasonable solutions in your area? Maybe we can help. If you think we can, either: 1) Mail your inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631-0651; 3) e-mail it to CW1Dean@aol.com, or 4) log onto www.cycleworld.com and click on the Feedback button. Please, always include your name, city and state of residence. Don’t write a 10page essay, but do include enough information about the problem to permit a rational diagnosis. And please understand that due to the enormous volume of inquiries we receive, we can’t guarantee a reply to every question.

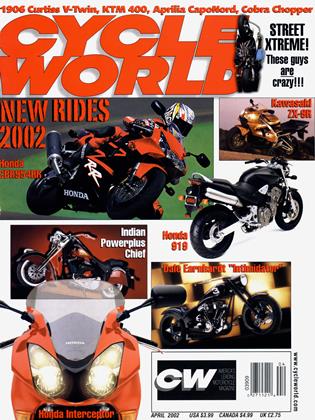

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontLetter of the Month

April 2002 By David Edwards -

Leanings

LeaningsThe Mouse That Roared

April 2002 By Peter Egan -

TDC

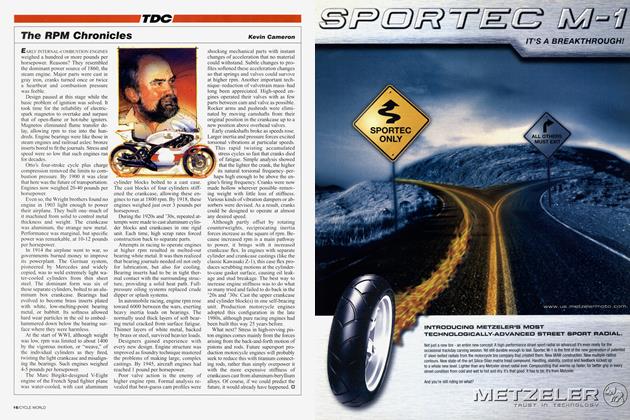

TDCThe Rpm Chronicles

April 2002 By Kevin Cameron -

Departments

DepartmentsHotshots

April 2002 -

Roundup

RoundupNew Bmw Über-Tourer Twin

April 2002 By Matthew Miles -

Roundup

RoundupUltimate Towing Machine?

April 2002 By David Edwards