Two crankshafts?

TDC

Kevin Cameron

IN HIS ROLLICKING R&B SONG, “JOHNNIE B. Goode,” Chuck Berry describes his subject sitting by the railroad tracks, “strummin’ with the rhythm that the drivers made.” Because steam locomotives are gone now, few people today even know about “drivers.” They are the long, heavy connecting rods of those big, old steam engines. One end connected to the crankpin on a drive wheel, and the other end hooked, not to a piston as in a car or motorcycle engine, but to a crosshead. The crosshead was a slider, generally moving between a pair of stationary guides that handled the side thrust generated by the changing angularity of the con-rod. From the crosshead, a piston rod entered the cylinder through a seal and bolted through the center of the disc-like piston.

Only later would the crosshead’s function be assumed by the pistons themselves, which grew from the discon-a-rod of the steam engine, into the familiar bucket shape of automotive pistons. This later type of piston is formally called a “trunk piston.” The connecting rod attaches directly to it via a wristpin, and it has large sliding surfaces on it-the skirts-to handle con-rod sidethrust loads without the weight and extra complication of a separate crosshead.

Side thrust remains a source of friction that engine designers and tuners try to minimize by reducing con-rod angularity with longer rods. Bear in mind that a longer rod does not increase an engine’s stroke-that is determined by how far offset the crankpin is from the crankshaft’s centerline. Others claim that shorter rods are better. As the rod is made shorter, there is a small increase in the time the piston spends near BDC. This, some believe, by increasing the time available for filling the cylinder, should increase power. Engine builders speak of rod length in terms of a rod ratio, which is the eye-to-eye con-rod length, divided by the engine’s stroke. Production motorcycle engines tend to have ratios close to 2.0 or higher, while race engines may have ratios up to 2.2.

Do short rods make more power? Some years ago, Circle Track magazine built two nearly identical smallblock Chevy engines-one with conrods an inch longer than the other, but with identical displacements, piston weights, ring packs and so on. Did the short-rod engine deliver? No such thing! The long-rod engine bettered or equaled the short-rod version at every point tested. When I first heard the idea that short rods increase piston BDC dwell and power, I looked for the dwell difference using a standard “Piston Travel Factors” chart. Between rod ratios of 1.75 and 2.25, the difference was too small to find.

Occasionally, there are special reasons to adopt rod ratios under 2.0. This was done on an early military radial engine to reduce its diameter and so its frontal area, but the engine was a clattering failure. Big-block auto engines usually have very short rods (rod ratio near 1.6) to make them fit into smallblock engine bays, but longer rods and taller blocks are invariably used in race versions of these same engines. Some Formula One engines also have rods on the short side (1.8 rod ratio) to achieve necessary engine packaging.

Other than these special cases, the real goal of rod-length choice is to reduce rod angularity on the power stroke, and thereby reduce friction loss from piston side thrust. An infinitely long rod would have zero angularity, zero side thrust and so reduced piston friction.

Race kits manufactured for Superbike engines feature longer-than-stock rods, with pistons whose wristpins have been relocated higher up to bring the pistons to the same height at TDC. In certain F1 engines, this process of fitting longer rods has adopted the device of actually boring the wristpin hole partly intersecting the oil ring groove, then supporting the oil ring by means of a circular plug (installed after the wristpin is in place) grooved to hold the ring.

If further demonstration is needed, have a look at any piston that has run a while. You will see a fairly dramatic difference in wear between the thrust skirt (the one pressed against the cylinder wall by rod angularity during the power strokes) and the non-thrust skirt.

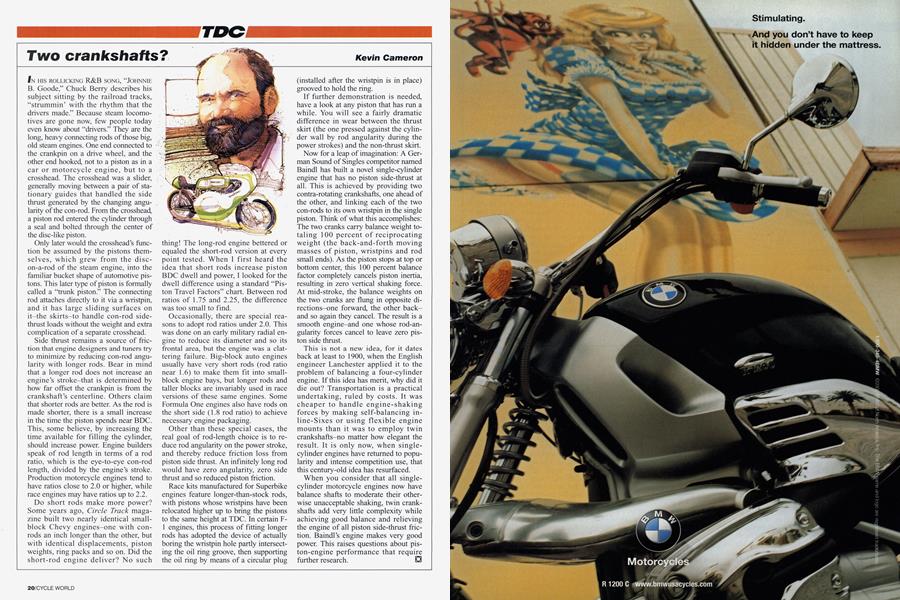

Now for a leap of imagination: A German Sound of Singles competitor named Baindl has built a novel single-cylinder engine that has no piston side-thrust at all. This is achieved by providing two contra-rotating crankshafts, one ahead of the other, and linking each of the two con-rods to its own wristpin in the single piston. Think of what this accomplishes: The two cranks carry balance weight totaling 100 percent of reciprocating weight (the back-and-forth moving masses of piston, wristpins and rod small ends). As the piston stops at top or bottom center, this 100 percent balance factor completely cancels piston inertia, resulting in zero vertical shaking force. At mid-stroke, the balance weights on the two cranks are flung in opposite directions-one forward, the other backand so again they cancel. The result is a smooth engine-and one whose rod-angularity forces cancel to leave zero piston side thrust.

This is not a new idea, for it dates back at least to 1900, when the English engineer Lanchester applied it to the problem of balancing a four-cylinder engine. If this idea has merit, why did it die out? Transportation is a practical undertaking, ruled by costs. It was cheaper to handle engine-shaking forces by making self-balancing inline-Sixes or using flexible engine mounts than it was to employ twin crankshafts-no matter how elegant the result. It is only now, when singlecylinder engines have returned to popularity and intense competition use, that this century-old idea has resurfaced.

When you consider that all singlecylinder motorcycle engines now have balance shafts to moderate their otherwise unacceptable shaking, twin crankshafts add very little complexity while achieving good balance and relieving the engine of all piston side-thrust friction. Baindl’s engine makes very good power. This raises questions about piston-engine performance that require further research.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontNed's Sled

August 2000 By David Edwards -

Leanings

LeaningsCharacter Infusion

August 2000 By Peter Egan -

Departments

DepartmentsHotshots

August 2000 -

Roundup

RoundupEurope Gets Naked!

August 2000 By Matthew Miles -

Roundup

RoundupIndian's Sporting Scout

August 2000 By Wendy F. Black -

Roundup

RoundupAccess Denied!

August 2000 By Charles Plueddeman