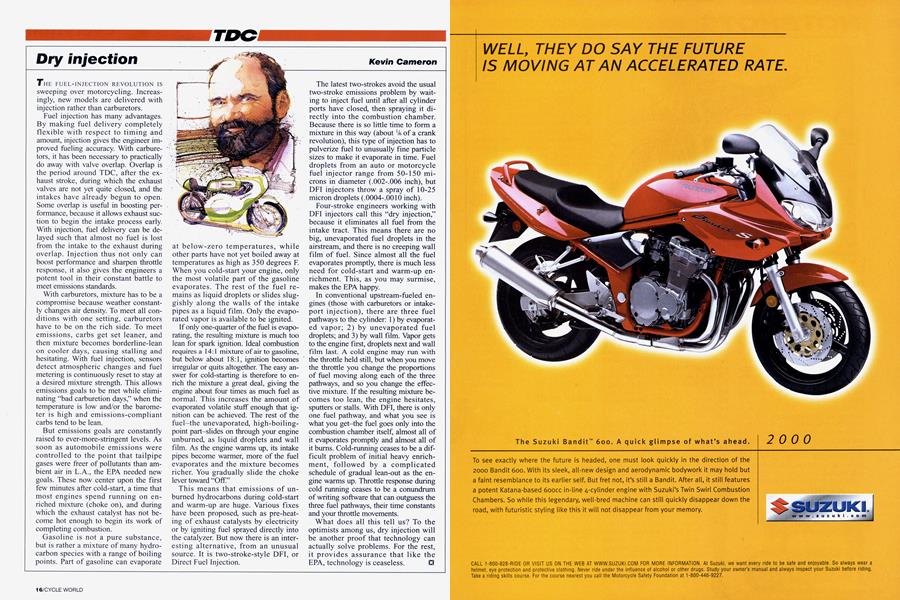

Dry injection

TDC

Kevin Cameron

THE FUEL-INJECTION REVOLUTION IS sweeping over motorcycling. Increasingly, new models are delivered with injection rather than carburetors.

Fuel injection has many advantages. By making fuel delivery completely flexible with respect to timing and amount, injection gives the engineer improved fueling accuracy. With carburetors, it has been necessary to practically do away with valve overlap. Overlap is the period around TDC, after the exhaust stroke, during which the exhaust valves are not yet quite closed, and the intakes have already begun to open. Some overlap is useful in boosting performance, because it allows exhaust suction to begin the intake process early. With injection, fuel delivery can be delayed such that almost no fuel is lost from the intake to the exhaust during overlap. Injection thus not only can boost performance and sharpen throttle response, it also gives the engineers a potent tool in their constant battle to meet emissions standards.

With carburetors, mixture has to be a compromise because weather constantly changes air density. To meet all conditions with one setting, carburetors have to be on the rich side. To meet emissions, carbs get set leaner, and then mixture becomes borderline-lean on cooler days, causing stalling and hesitating. With fuel injection, sensors detect atmospheric changes and fuel metering is continuously reset to stay at a desired mixture strength. This allows emissions goals to be met while eliminating “bad carburetion days,” when the temperature is low and/or the barometer is high and emissions-compliant carbs tend to be lean.

But emissions goals are constantly raised to ever-more-stringent levels. As soon as automobile emissions were controlled to the point that tailpipe gases were freer of pollutants than ambient air in L.A., the EPA needed new goals. These now center upon the first few minutes after cold-start, a time that most engines spend running on enriched mixture (choke on), and during which the exhaust catalyst has not become hot enough to begin its work of completing combustion.

Gasoline is not a pure substance, but is rather a mixture of many hydrocarbon species with a range of boiling points. Part of gasoline can evaporate at below-zero temperatures, while other parts have not yet boiled away at temperatures as high as 350 degrees F. When you cold-start your engine, only the most volatile part of the gasoline evaporates. The rest of the fuel remains as liquid droplets or slides sluggishly along the walls of the intake pipes as a liquid film. Only the evaporated vapor is available to be ignited.

If only one-quarter of the fuel is evaporating, the resulting mixture is much too lean for spark ignition. Ideal combustion requires a 14:1 mixture of air to gasoline, but below about 18:1, ignition becomes irregular or quits altogether. The easy answer for cold-starting is therefore to enrich the mixture a great deal, giving the engine about four times as much fuel as normal. This increases the amount of evaporated volatile stuff enough that ignition can be achieved. The rest of the fuel-the unevaporated, high-boilingpoint part-slides on through your engine unburned, as liquid droplets and wall film. As the engine warms up, its intake pipes become warmer, more of the fuel evaporates and the mixture becomes richer. You gradually slide the choke lever toward “Off.”

This means that emissions of unburned hydrocarbons during cold-start and warm-up are huge. Various fixes have been proposed, such as pre-heating of exhaust catalysts by electricity or by igniting fuel sprayed directly into the catalyzer. But now there is an interesting alternative, from an unusual source. It is two-stroke-style DFI, or Direct Fuel Injection.

The latest two-strokes avoid the usual two-stroke emissions problem by waiting to inject fuel until after all cylinder ports have closed, then spraying it directly into the combustion chamber. Because there is so little time to form a mixture in this way (about VÓ of a crank revolution), this type of injection has to pulverize fuel to unusually fine particle sizes to make it evaporate in time. Fuel droplets from an auto or motorcycle fuel injector range from 50-150 microns in diameter (.002-,006 inch), but DFI injectors throw a spray of 10-25 micron droplets (.0004-.0010 inch).

Four-stroke engineers working with DFI injectors call this “dry injection,” because it eliminates all fuel from the intake tract. This means there are no big, unevaporated fuel droplets in the airstream, and there is no creeping wall film of fuel. Since almost all the fuel evaporates promptly, there is much less need for cold-start and warm-up enrichment. This, as you may surmise, makes the EPA happy.

In conventional upstream-fueled engines (those with carburetors or intakeport injection), there are three fuel pathways to the cylinder: 1 ) by evaporated vapor; 2) by unevaporated fuel droplets; and 3) by wall film. Vapor gets to the engine first, droplets next and wall film last. A cold engine may run with the throttle held still, but when you move the throttle you change the proportions of fuel moving along each of the three pathways, and so you change the effective mixture. If the resulting mixture becomes too lean, the engine hesitates, sputters or stalls. With DFI, there is only one fuel pathway, and what you see is what you get-the fuel goes only into the combustion chamber itself, almost all of it evaporates promptly and almost all of it bums. Cold-running ceases to be a difficult problem of initial heavy enrichment, followed by a complicated schedule of gradual lean-out as the engine warms up. Throttle response during cold running ceases to be a conundrum of writing software that can outguess the three fuel pathways, their time constants and your throttle movements.

What does all this tell us? To the optimists among us, dry injection will be another proof that technology can actually solve problems. For the rest, it provides assurance that like the EPA, technology is ceaseless.