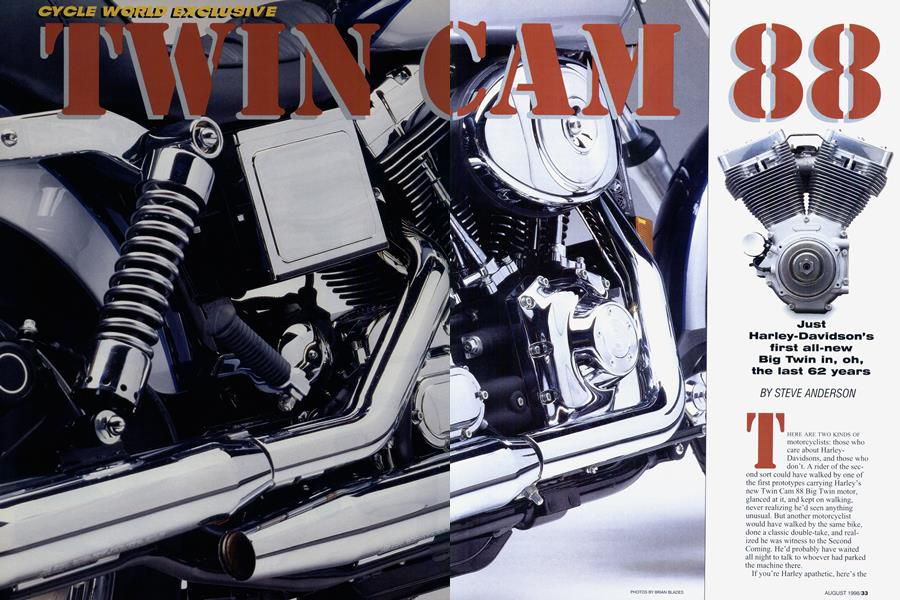

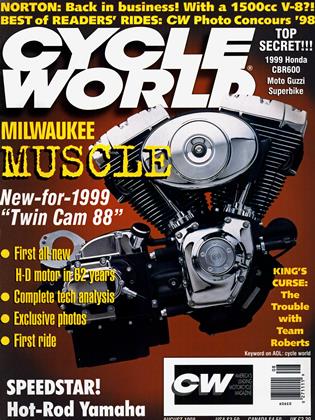

TWIN CAM 88

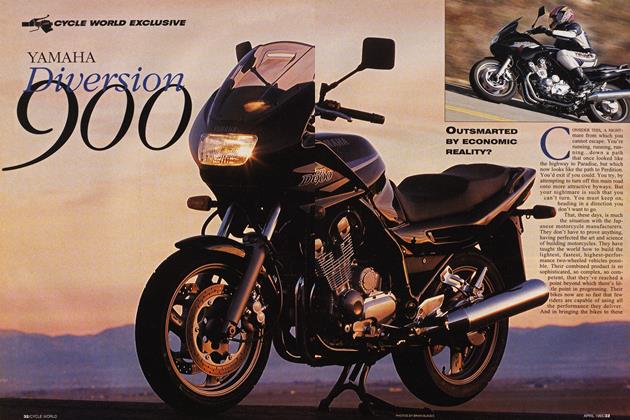

CYCLE WORLD EXCLUSIVE

Just Harley-Davidson's first all-new Big Twin in, oh, the last 62 years

STEVE ANDERSON

THERE ARE TWO KINDS OF motorcyclists: those who care about HarleyDavidsons, and those who don't. A rider of the second sort could have walked by one of the first prototypes carrying Harley's new Twin Cam 88 Big Twin motor, glanced at it, and kept on walking, never realizing he'd seen anything unusual. But another motorcyclist would have walked by the same bike, done a classic double-take, and realized he was witness to the Second Coming. He'd probably have waited all night to talk to whoever had parked the machine there.

If you're Harley apathetic, here's the short version: Harley-Davidson has designed the first completely new Big Twin since the overhead-valve powerplant first appeared in 1936-so new it shares just 18 parts with the old. It's 1 lOcc bigger than an Evolution Big Twin at 1450cc, and promises to be far stronger and more reliable, to be both torquier and higher-revving, to vibrate less while making less mechanical noise, and to lead , Harley solidly into the new - millennium. It'll power all * Dyna and FL touring models for 1999 and beyond, and Softails someday.

Big news, in other words, but because one of the primary goals of the new design was to do a Big Twin that was fundamentally the same as the old one, only better, you need at least a hint of why someone might adorn their biceps with a Harley-Davidson tattoo to fully appreciate it.

notching on the flyOf course, more than 100,000 wheel is used to deter motorcyclists voted with their mine ignition timing. pocketbooks last year to make the Harley Evo Big Twin by far the most popular large-displacement powerplant in motorcycling, even though it can't be found in any machine that showroom stickers at anything less than $11,000. For these true believers out there, know this: When Billy Davidson, son of Willie G. and a member of Harley's product-planning staff, pulled the wraps off this new engine for us, his eyes were wet. "Now I know a little bit about how my grandfather must have felt when the first Big Twin came down the assembly line in 1936," said the man whose name is still on the gas tanks. Twin should be." The priority list was long. Any new Big Twin should set standards for reliability and durability. It should offer more performance stock, and more potential for hop-up. It should leak no oil, ever. It should be quieter mechanically. It should be easier to manufacture and to assemble, both for reasons of cost and quality. In short, it should be a Harley Big a Harley Big Twin, just like the Evolution, but better-much better. The project started simply in the early Nineties, initially driven by the engineering department. The bottom end on an Evolution Big Twin was the weak link for hot-rodded engines, and Harley owners building big-bores or strokers were turning to aftermarket suppliers such as S&S Engineering for stronger cases, cranks and rods. That didn't sit well in Milwaukee, and the engineers set out to do something about it. The first response was a crank with a massively bigger straight crankpin (1 Vs-inch versus the 11/4inch tapered-fit pin on an Evolution). But the stronger,

When you first see the new engine, you know it's a Big Twin, but different. "For us to build something other than a 45-degree, air-cooled V-Twin would be crazy," said Davidson, so the new engine is that, and recognizably close kin to the current Evolution motor. The most striking of the cosmetic differences are the enlarged cylinder and head finning, the two-piece rocker covers with angled splitlines, the completely changed cam and timing covers, the more substantial attachment of the still-separate gearbox to the rear of the engine, and the new oval air filter. But the appearance changes are, for want of a better word, evolutionary, not revolutionary.

That's all part of the plan, explained our Milwaukee hosts. Walking us through the new powerplant with Davidson were a few of its parents: Bob Kobylarz, head of Harley engine engineering; Skip Metz, engineering head of the Twin Cam 88 project; and Don Kieffer, overall project leader for the new powerplant. "The real challenge," said Kieffer, "was to combine all the voices who wanted their say on what a new Big Twin should be."

stiffer prototype crankshaft just transferred the loads elsewhere, cracking the standard Evolution crankcases. New cases were needed, ideally with a bigger main bearing on the cam side-but that meant relocating the cam. It was becoming obvious that what was being demanded wasn't a refinement of the Evolution, but a whole new engine.

When a decision percolated through The Motor Company that an all-new engine could and should be done, it brought with it the freedom to change. Knife-and-fork connecting rods and inline cylinders would stay, as would pushrods, because they were defining characteristics of Big Twin engines, and worked well enough over the engine speed range desired. But any new engine would have to be mechanically quieter than the old-noise regulations, you know-and that meant a quiet cam-drive chain should substitute for noisy and expensive gears. But a camchain needs greater center-to-center distance than a gear drive, and that drove the camshaft farther from the crank. Good if you want a big bearing, but...a single highmounted camshaft tucked up further into the engine's vee with sharply angled pushrods simply looked weird.

The styling department in the person of Willie G. Davidson demanded another solution. The one found became the defining characteristic of the new engine: twin camshafts. Each cylinder would get its own cam mounted directly along its axis. A single camchain would drive from the crank to the rear cam, while another chain would drive from that cam to the second.

For the crankcases themselves, part of the new design was relatively straightforward, and part of it was literally an oily mess. Kobylarz explained, "Historically, the design process has been design, build, test and break, then design again. That's an expensive process. This time, we said, `Let's take the money to analyze in computer modeling before going to hardware.' That way, we end up with two deliverables: first, an improved product; and second, new capabilities and new competency in Harley-Davidson powertrain engineering we can apply to the next project." So the new cases were likely the most thoroughly studied parts in Harley history, stressed and twisted and hammered to failure while they were nothing more than a finite-element mesh on a cathode-ray tube, then redesigned until they could take any load anticipated, and then some. "We put the metal in the right places," said Metz, explaining the new design was so much superior as to allow the cases to be made via high-quality die casting (by die-casting expert Mercury Marine), and that the new cases actually are lighter-while being much stronger-than the old.

But the biggest design problem of the new engine wasn't one amenable to numerical analysis: creating a new oiling system. Big Twins, since their Knucklehead beginnings in 1936, have used a "timed breather" connecting crankcase to carnease. That's because the pistons on a 45-degree motor rise and fall closely together, leading to big shifts in the volume trapped in the crankcase under the pistons, and equally big pressure shifts. With their active connection between the crankcase and the adjacent cam cavity, all previous Big Twins have sought to use these pressure changes to move oil out of the crankcase on the down stroke and to create a power-enhancing partial vacuum under the pistons on the upstroke. But under continuous higher-speed operation, Big Twins have had a tendency to "sump," with excessive oil becoming trapped in the crankcases, creating problems with oil control and power losses.

Given their experience, it was natural enough for Harley engineers to investigate active control of crankcase venting through either timed breathers or reed valves when they sought to build an improved oil system for the new engine. But hundreds and hundreds of hours spent running a prototype fitted with plexiglass portholes on a motoring dyno (a dyno that drives a non-firing engine, rather than the normal reverse) demonstrated there was nothing easy about keeping oil where you wanted it and nowhere else. At one point, related Kieffer, "We wanted to dig up Bill Harley (designer of the first Big Twin) and ask him how to do it.'

Fortunately, the solution wasn't to be found in a seance, but in simplification. The final design is elegant. A gerotortype pump runs directly on the end of the right crankshaft, at crank speed. One rotor of the pump supplies pressurized oil; the other, roughly 2.5 times wider, overscavenges a small chamber at the bottom of the crankcases and the carnease separately through two passages. The only connection between the carnease and the crankcase are the spaces between the big rollers of the right-side main bearing and the needles on the cam bearings. "The pumping dyno showed this kept things quieter," said Metz, referring to the oil flow. The gaps between bearings provide sufficient area to keep pressures between the chambers roughly equal. The overscavenging helps pull crankcase pressure down below atmospheric. And the air-oil mist pulsing between the two chambers lubricates the right-side main bearing and the cam bearings without any other source of supply. But most importantly, the crankcase runs dry no matter how fast or hard the Twin Cam is pressed. Kobylarz summed it up, "We're not intimidated by oil systems on Big Twins anymore. We didn't understand how it worked; now we do."

Along with the improved structure and oiling came a raft of detail changes to enhance reliability and durability. New rods were designed to work with the bigger crankpin, and without the pressed-in bearing insert used previously. Why? The pressing operation created stresses in the rods that sometimes led to the big-end of an Evo rod going out of round, resulting in bearing noise. But by hardening the bigends of the new rods directly, the insert could be eliminated, and the rod made much stronger and more stable. The crankpin became a straight-in press-fit, rather than the previous tapered fit pulled together by nuts on the ends; with a heavy, .007-inch press, the new crank is stiffer and stronger.

Oil leaks were a particular target during the development of the Twin Cam, with one engineer assigned the sole duty of eliminating them. His handiwork can be seen in numerous places, from the absence of a cylinder base gasket (now a metal-to-metal joint sealed by an 0-ring) to the expensive metal-core gaskets for the rocker covers. Leaks were quan tified, with a scale ranging from a genuine leak, to wet dust appearing at the edge of a fiber gasket, to dry dust attaching itself to the same gasket. Only the last was acceptable, and more than 60 design changes were made to ensure that result. According to Metz, "The final 250-hour accelerated durability tests were completely dry."

In fact, the Harley engineers are proudest of the Twin Cam's durability, and can roll off its testing credits like mothers talking about their children's outstanding school grades. "The Evo had a 100-hour bogey on the accelerated durability test," said Metz, explaining how that test runs through the entire operating range, with full power demanded 60 percent of the time. "The new engine had to pass a 250-hour version, with one of the test engines actually running 400 hours. In total, we've tested the Twin Cam for 2.5 million miles, and 14,000 hours on the dyno. Individual bikes have run more than 100,000 miles through HarleyDavidson's test process and are still going strong."

Performance enhancements were intended to complement improved durability from the beginning. According to the engineers, the initial design displaced only 1350cc; the intent was to increase power through more sophisticated engine tuning. Reality quickly set in. Given noise constraints, no big power increase with a suitable powerband could be produced. Displacement was the answer; according to Kobylarz, "We calculated a bore and stroke that would give us shaking forces comparable or slightly less than a 1340 Evo. We wanted improvements that would be noticeable." They arrived at 1450cc (88 cubic inches) through a 3.75-inch bore and a 4.00-inch stroke, dimensions a quarterinch greater and a quarter-inch shorter, respectively, than those of an 80-cubic-inch Evo powerplant.

Because better bore stability was desired (Evo bores don't always stay round, particularly if they've gotten really hot), the stud pattern was widened, and a ,075-inch-thicker liner is used. For better heat transfer and stability, the new iron liner carries the Spinilock ribbing that ties liner to aluminum casting all the way to the top of the cylinder-Evos drop the ribbing near the top to make way for a flange. Even the holes the studs pass through were downsized to increase liner support. A new bathtub-shaped combustion chamber is smoother than the Evo chamber, and its 85cc size gives a 9.0:1 compression ratio-requiring a premium gasoline recommendation. An important part of the performance package was the new oval air filter, designed with the latest in Harley's WAVE analysis software. Larger in volume than the current round filter, it quiets intake honk with less flow restriction. And its oval appearance grows on you; we found ourselves liking it after a few hours of exposure.

By 1996, the Twin Cam's architecture was largely set. Cylinder heads were closely based on the Evo design (a four-valve setup was considered but rejected as unneeded), with changes made for the new stud pattem. Intake and exhaust valves were located similarly, and Evo rocker arms were retained. But the most extensive testing program in The Motor Company's history revealed the engine had one weakness: higher oil and piston temperatures than desired under certain very adverse conditions.

An oil cooler would have cured the problem, but a decision was made to fix the thermal problems more fundamentally. Only then was the increased cylinder and head finning added-an astonishing admission as these are the most prominent visual cues to the new engine, and the most handsome. Also added were oil jets that spray a cooling stream at the bottom of the pistons, and baffles in the gearbox-located oil pan to hold oil longer, and let it cool more.

To keep heat out of the oil in the first place, oil flow was restricted to the cylinder heads-tests showed that Evo levels of oil flow supplied more oil than needed to lubricate the rockers, and that greater-than-necessary flow was more effective in adding heat to the oil than in dropping cylinderhead temperatures. And the exhaust valve and port were decreased in size while being better streamlined-the valve using a Jim Feuling-patented design-to increase flow speed in the exhaust port, and decrease the likelihood of flow reversion and the heat it adds.

The sum of the numerous changes dropped temperatures significantly. According to Kobylarz, the new engine may get hot (as would any air-cooled engine under conditions of low cooling airflow), but compared to an Evo, "It's far more survivable under those conditions."

Other changes are part of Harley's long-standing battle against mechanical engine noise. Any noise made by internal components means the exhaust has to be that much more restrictive, and its note that much less distinct. So the 88's engine covers were designed to be just that-covers, and not bearing supports or anchors for moving parts. As pure covers, they could be studied and shaped to minimize their noise-transmission characteristics. So the rockers are carried by a new casting separate from the rocker covers, and the cam cover on the right side pulls off to reveal a spidery plate carrying the outside cam bearings and oil pump.

But enough details for a second, and on to the real question: What is the new engine like in a bike? We had an opportunity to briefly sample a pre-production 1999 Dyna Wide Glide and Dyna Convertible fitted with Twin Cam 88s, and can report that the first impression is definitely visual. The meatfly finned cylinders and heads fill up the frames more thoroughly, in a very classic motorcycle way.

In comparison, an Evo starts to look just a bit wimpy. A push on the starter button, and the Twin Cam 88 jumps to life much like an Evo, rumbling gently in the rubber mounts of a DynaGlide frame. We were riding on a cold, early April morning in Wisconsin, and the jetting of these two machines was a little on the lean side, requiring considerable warm-up, and giving a slight lean hesitation when twisting the throttle from a constant cruising speed. We'd recommend a one-size jump in the pilot jet if this jetting makes production (all Dyna Twin Cams retain the Keihin CV carburetor of the Evo, while some FL touring models will be fuel injected). Once warm, both bikes pulled well and smoothly from the bottom, notably stronger than a stock Evo, and really came to life by 3500 rpm. The Twin Cam's crank is heavier than an Evo's, but its flywheels push some of that weight to a smaller radius; the result is a 27 percent reduction in flywheel effect. And you feel those lighter-acting flywheels with each twist of the throttle, the engine far quicker-revving and far more responsive than a stock Evo. From the 3500-rpm torque peak to the 5500-rpm redline and another few hundred rpm beyond, the Twin Cam revs out hard and happy, running like no showroom Big Twin ever-Evos get listless before they've touched their 5000-rpm redline. If Harley's power claims are accurate, a stock Twin Cam may put out 10 horsepower more than an Evo at the rear wheel (perhaps 62 horses), with more torque everywhere. The difference doesn't transform a stock Twin Cam into a rocket ride-there are far stronger hot-rodded Evos out there-but it does make it one of the strongestrunning of any of the stock V-Twin cruisers, same shorty dual mufflers that clog up an Evo's exhaust. One thing Harley's engineers are sure of: This new powerplant will respond readily to tuning, and is strong enough to take it.

They're also sure that the wide bolt pattern and flat-face joining engine to gearbox (the RRI, or "Revised Rear Interface," in Harley engineering jargon) dramatically increases frame stiffness on Dyna models. Dynas react swingarm sideloads directly into the gearbox, which in turn wants to pivot around the narrowly spaced bolts that mount gearbox to engine on Evolution models. The engineers say the new gearbox mounting translates into surer handling; we say that the Twin Cam Dynas we rode were solid-handling, but whether that was due to the RRI or not awaits back-to-back testing.

testing. But mostly, with a stock Twin Cam 88 rumbling under you, you're aware that Harley has refined the Big Twin concept, not transformed or forsaken it. Gentle engine vibration still pulses through the rubber mounts, and the Twin Cam still wants to run in high gear, with monstrous torque to pull you forward rather than the high-speed howl into hyperspace found in the sportbike world. This is a Big Twin with a broader range and scope, with the promise of greater reliability and refinement, with a long list of factory hop-up parts just waiting to be introduced for people who want 80plus horsepower and 100 foot-pounds of torque at the rear wheel. It may be all-new, but the people who designed it still know why the Big Twin of 1936 endured (and continues to endure in the Softail range) as one of the longest-lived engines ever.

And all you have to do is listen to them to know they've just begun: "This engine," said Kobylarz, "is most important; with it, we solidify our foundation in a product that's traditionally Harley-Davidson. We've learned that the 45degree, air-cooled V-Twin has a future.

We'll continue to apply new technology to give it that future." Davidson continued, "Now we're starting to dig into product. The Twin Cam 88 is just the beginning; we're not sleeping, we're working hard." "Yes," said Kieffer, "the Twin Cam 88 gives us a license to dream." And while he and the others are dreaming Harley's mechanical future, the rest of us can be riding the best Big Twin ever. □

View Full Issue

View Full Issue