Burn Baby Burn

VALVES AND MORE VALVES

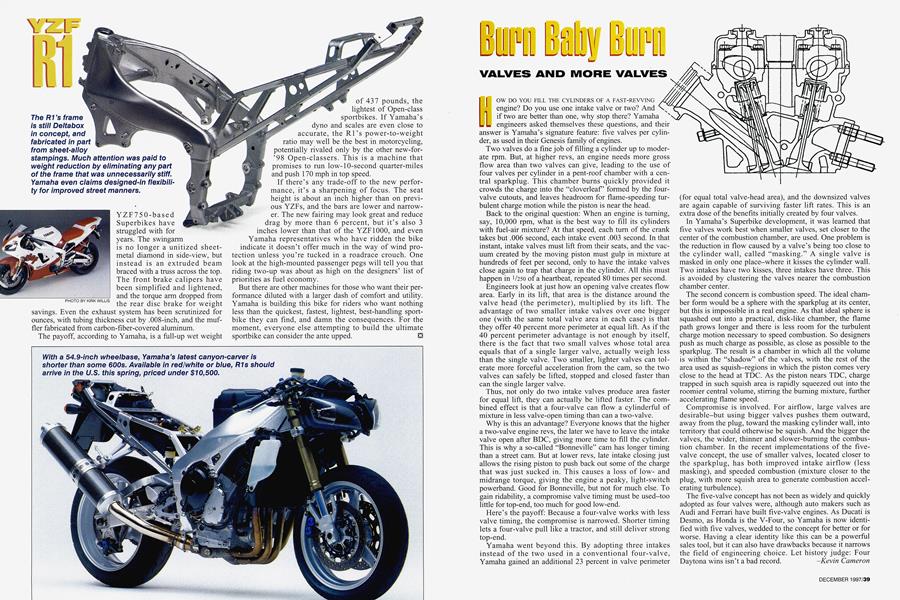

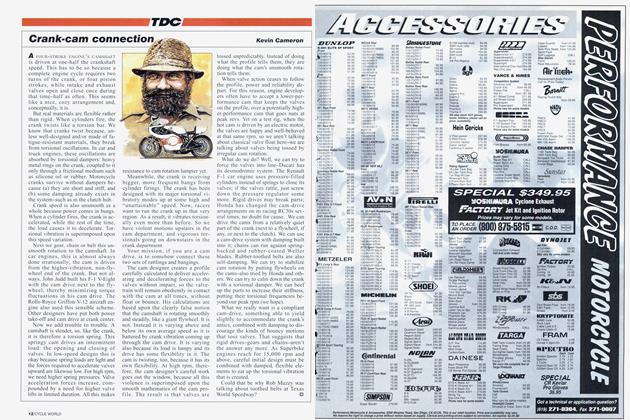

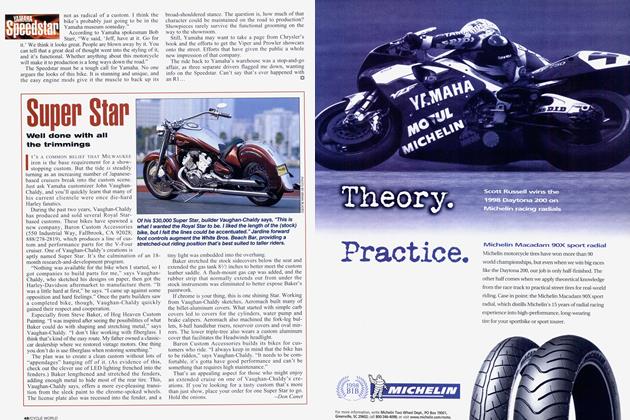

HOW DO YOU FILL THE CYLINDERS OF A FAST-REVVING engine? Do you use one intake valve or two? And if two are better than one, why stop there? Yamaha engineers asked themselves these questions, and their answer is Yamaha's signature feature: five valves per cylinder, as used in their Genesis family of engines.

Two valves do a fine job of filling a cylinder up to moder ate rpm. But, at higher revs, an engine needs more gross flow area than two valves can give, leading to the use of four valves per cylinder in a pent-roof chamber with a cen tral sparkplug. This chamber burns quickly provided it crowds the charge into the "cloverleaf" formed by the four valve cutouts, and leaves headroom for flame-speeding tur bulent charge motion while the piston is near the head.

Back to the original question: When an engine is turning, say, 10,000 rpm, what is the best way to fill its cylinders with fuel-air mixture? At that speed, each turn of the crank takes but .006 second, each intake event .003 second. In that instant, intake valves must lift from their seats, and the vac uum created by the moving piston must gulp in mixture at hundreds of feet per second, only to have the intake valves close again to trap that charge in the cylinder. All this must happen in 1/250 of a heartbeat, repeated 80 times per second. Engineers look at just how an opening valve creates flow area. Early in its lift, that area is the distance around the valve head (the perimeter), multiplied by its lift. The advantage of two smaller intake valves over one bigger one (with the same total valve area in each case) is that they offer 40 percent more perimeter at equal lift. As if the 40 percent perimeter advantage is not enough by itself, there is the fact that two small valves whose total area equals that of a single larger valve, actually weigh less than the single valve. Two smaller, lighter valves can tol erate more forceful acceleration from the cam, so the two valves can safely be lifted, stopped and closed faster than can the single larger valve. -

Thus, not only do two intake valves produce area faster for equal lift, they can actually be lifted faster. The com bined effect is that a four-valve can flow a cylinderful of mixture in less valve-open timing than can a two-valve. Why is this an advantage? Everyone knows that the higher a two-valve engine revs, the later we have to leave the intake valve open after BDC, giving more time to fill the cylinder. This is why a so-called "Bonneville" cam has longer timing than a street cam. But at lower revs, late intake closing just allows the rising piston to push back out some of the charge that was just sucked in. This causes a loss of lowand midrange torque, giving the engine a peaky, light-switch powerband. Good for Bonneville, but not for much else. To gain ridability, a compromise valve timing must be used-too little for top-end, too much for good low-end. Here's the payoff: Because a four-valve works with less valve timing, the compromise is narrowed. Shorter timing lets a four-valve pull like a tractor, and still deliver strong top-end.

Yamaha went beyond this. By adopting three intakes instead of the two used in a conventional four-valve, Yamaha gained an additional 23 percent in valve perimeter (for equal total valve-head area), and the downsized valves are again capable of surviving faster lift rates. This is an extra dose of the benefits initially created by four valves. In Yamaha's Superbike development, it was learned that five valves work best when smaller valves, set closer to the center of the combustion chamber, are used. One problem is the reduction in flow caused by a valve's being too close to the cylinder wall, called "masking." A single valve is masked in only one place-where it kisses the cylinder wall. Two intakes have two kisses, three intakes have three. This is avoided by clustering the valves nearer the combustion chamber center.

The second concern is combustion speed. The ideal cham ber form would be a sphere with the sparkplug at its center, but this is impossible in a real engine. As that ideal sphere is squashed out into a practical, disk-like chamber, the flame path grows longer and there is less room for the turbulent charge motion necessary to speed combustion. So designers push as much charge as possible, as close as possible to the sparkplug. The result is a chamber in which all the volume is within the "shadow" of the valves, with the rest of the area used as squish-regions in which the piston comes very close to the head at TDC. As the piston nears TDC, charge trapped in such squish area is rapidly squeezed out into the roomier central volume, stirring the burning mixture, further accelerating flame speed.

Compromise is involved. For airflow, large valves are desirable-but using bigger valves pushes them outward, away from the plug, toward the masking cylinder wall, into territory that could otherwise be squish. And the bigger the valves, the wider, thinner and slower-burning the combus tion chamber. In the recent implementations of the five valve concept, the use of smaller valves, located closer to the sparkplug, has both improved intake airflow (less masking), and speeded combustion (mixture closer to the plug, with more squish area to generate combustion accel erating turbulence).

The five-valve concept has not been as widely and quickly adopted as four valves were, although auto makers such as Audi and Ferrari have built five-valve engines. As Ducati is Desmo, as Honda is the V-Four, so Yamaha is now identi fied with five valves, wedded to the concept for better or for worse. Having a clear identity like this can be a powerful sales tool, but it can also have drawbacks because it narrows the field of engineering choice. Let history judge: Four Daytona wins isn't a bad record. Kevin Cameron

View Full Issue

View Full Issue