A matter of a pinion

TDC

Kevin Cameron

GEARS ARE PLEASING OBJECTS. WHEN you look at the load path between two gears, you can see that the teeth are just stiff, stubby levers that bear against one another, one pair after an other, artfully shaped to transmit smooth, vibration-free rotation.

Motorcycle transmission gears are made of steels that can be heat-treated to produce a tough, impact-resistant core, with the tooth surfaces made very hard by nitriding or carburizing. A simple concept combined with cor rect materials and precise manufactur ing results in a very compact power transmission device that can last for millions of revolutions.

When adequately lubricated and supported, gears can transmit power at 98-percent efficiency; put a hundred horsepower in, get 98 horsepower out, and lose only 2 horsepower as fric tion's tax, paid in heat.

In the `60s, a dramatic improvement in the life of ball and roller bearings was achieved through the use of very "clean" (having a low population of inclusions and other possible sources of internal cracking) steels. Because gears experience the same high con tact stresses as bearings, their lives are likewise extended by clean steelssteels that have been re-melted in an electric furnace (or by electron beam), under a vacuum, allowing contami nants to vaporize and be pumped away. Such steel is expensive-a major part of the price of a high-class gear.

Whatever material is used, gears begin life as blanks, which may be sawn from bar or forged. With the steel in a soft, or annealed, state, the teeth are rough-cut on a bobbing machine. A worm-like toothed cutter-the hob-is fed into the blank, driving it around as its cutting action generates the teeth, deeper and deeper, chips spewing and coolant splattering. Splines or other features are also cut at this point.

(lears can transmit moderate power well with an as-hobbed finish. Those destined for use without further fin ishing will now be hardened and heattreated, and that will be that. Certain gear steels deform very little during heat-treatment, so the resulting tooth profiles are not too bad. Many pro duction transmission gears are made in this way, and as long as their design power levels aren't exceeded by much, they work fine. When new, hobbed teeth show irregular tool marks. In service, these marks usually polish away, leaving relatively smooth sur faces that bear load without too much local concentration.

Trouble starts when we boost the power of stock engines. Can a 40horsepower transmission find happi ness transmitting 90 horsepower? Kawasaki's three-cylinder two-stroke 500 racers of the early 1970s provide a case in point. After a couple of races, little lines of pits would appear across the loaded faces of the first-gear pin ion's teeth. Why first, and why the pin ion and not the mating gear? First usually fails initially because, being the smallest, it has maximum leverage and therefore maximum tooth-to-tooth pressure. The pinion also fails first be cause, having fewer teeth and so spinfling faster than the gear, its teeth experience more fatigue cycles. A couple of races later, these pits would enlarge into large eroded regions. Fi nally, they would break.

Tooth-to-tooth pressure causes tremendous shear stress, which is at its maximum just below the tooth surface. A poor surface finish concentrates this load, bringing failure sooner. A poor material provides more interior defects from which cracks may propagate.

Our own problems with the Kawa saki 500 were resolved adequately by upgrading the gear oil. We had tried everyone's favorite solution-20-5O en gine oil, 40 castor, even the red, wa tery ATF much beloved of those who believe they will go lots faster with thinner oil. Still, the teeth pitted and broke. The good stuff turned out to be Hypoid 90, designed for car and truck rear-axle gears. With it, the pitting stopped. Gear oils are loaded with highly effective extreme-pressure ad ditives-good medicine for what usual ly ails overworked gears. This heavy gear oil is fine in dry-clutch engines, but sticks a wet clutch together so wonderfully that, with a cold engine, it may be physically impossible to get out of neutral while standing still.

When Kawasaki replaced its 500 racer with a similar but much highertorque 750, the designers retained the same basic gearbox, saving the cute little thing from certain death by speeding up the primary ratio. This reduced the engine's leverage on the gearbox enough that tooth-to-tooth forces remained about the same as in the soo. Of course, fatigue cycles ac cumulated faster because of the higher gearbox shaft speeds. To compensate, the company improved the surface finish of the gears by rough-cutting on the hob, then hardening, before finishing the teeth by precision grind ing. This eliminated the hob-marks and any tooth distortion caused by heat-treatment. These were deluxe gears that never failed. I loved them. Unfortunately, you can't use real gear oils in most modern four-stroke motorcycle gearboxes, because they share the engine's oil. To live on much lighter-duty oils, the gears are either made larger in diameter (to reduce the tooth-to-tooth forces) or wider (to spread them over a larger area). They may also be highly finished.

The anti-wear additives in motor oils are rapidly used up in the highpressure zones between gear teeth. Oils that would perform well for thou sands of miles in an auto engine gen erally degrade much more quickly in a motorcycle engine. On the benefit side, the shared-oil scheme simplifies the engine, since there's no need to segregate engine and gear oils. Be cause there is already an oil pump, oil can be circulated into the gearbox shafts from the ends to lube the freespinning gears, and sprayed down on the meshes from jets above.

Only in that oil-rich environment can the gear expect to survive.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontAndy Rooney Rides

July 1992 By David Edwards -

Leanings

LeaningsThe Whites of Their Eyes

July 1992 By Peter Egan -

Letters

LettersLetters

July 1992 -

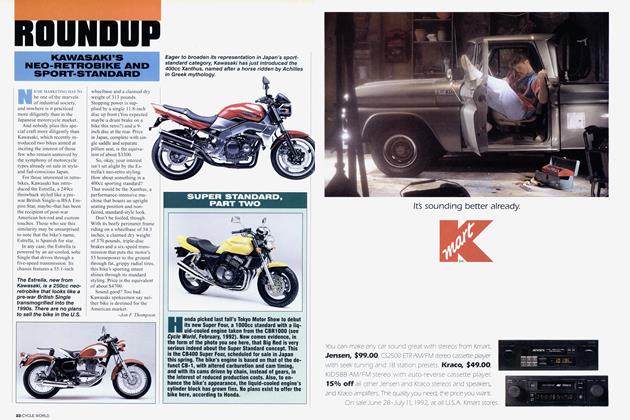

Roundup

RoundupKawasaki's Neo-Retrobike And Sport-Standard

July 1992 By Jon F. Thompson -

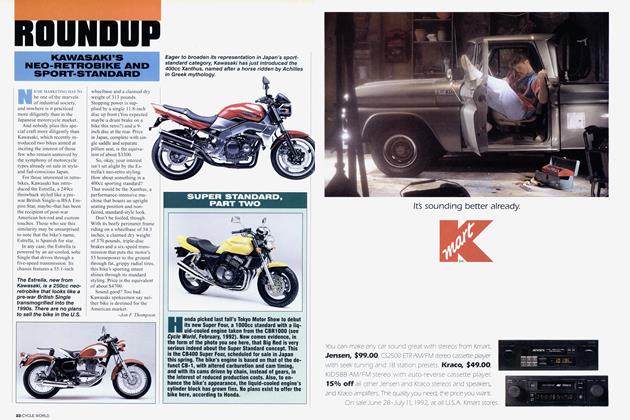

Roundup

RoundupSuper Standard, Part Two

July 1992 -

Roundup

RoundupReturn of the Super Hawk?

July 1992 By Jon F. Thompson