Small things

TDC

Kevin Cameron

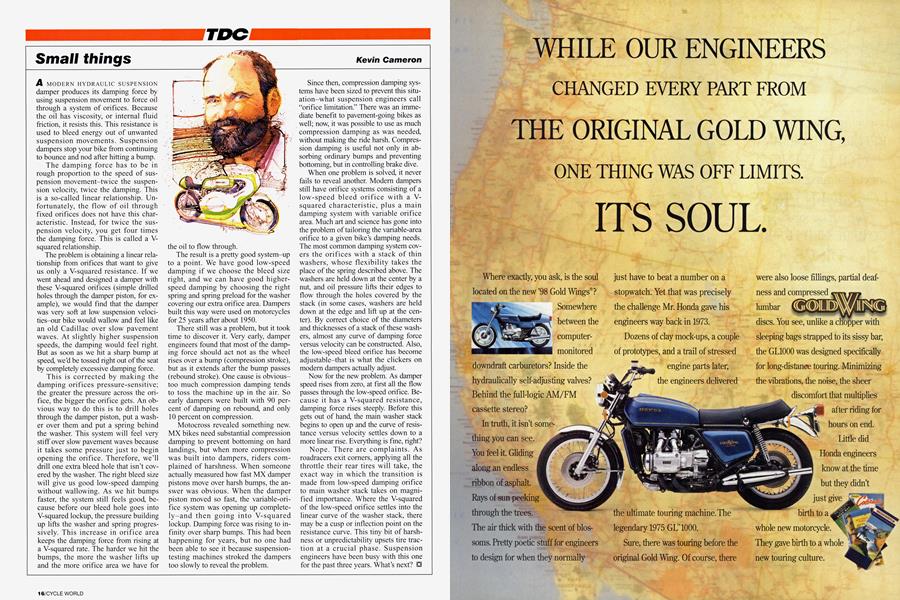

A MODERN HYDRAULIC SUSPENSION damper produces its damping force by using suspension movement to force oil through a system of orifices. Because the oil has viscosity, or internal fluid friction, it resists this. This resistance is used to bleed energy out of unwanted suspension movements. Suspension dampers stop your bike from continuing to bounce and nod after hitting a bump.

The damping force has to be in rough proportion to the speed of suspension movement-twice the suspension velocity, twice the damping. This is a so-called linear relationship. Un fortunately, the flow of oil through fixed orifices does not have this char acteristic. Instead, for twice the suspension velocity, you get four times the damping force. This is called a Vsquared relationship.

The problem is obtaining a linear rela tionship from orifices that want to give us only a V-squared resistance. If we went ahead and designed a damper with these V-squared orifices (simple drilled holes through the damper piston, for ex ample), we would find that the damper was very soft at low suspension veloci ties-our bike would wallow and feel like an old Cadillac over slow pavement waves. At slightly higher suspension speeds, the damping would feel right. But as soon as we hit a sharp bump at speed, we'd be tossed right out of the seat by completely excessive damping force.

This is corrected by making the damping orifices pressure-sensitive; the greater the pressure across the ori fice, the bigger the orifice gets. An ob vious way to do this is to drill holes through the damper piston, put a wash er over them and put a spring behind the washer. This system will feel very stiff over slow pavement waves because it takes some pressure just to begin opening the orifice. Therefore, we'll drill one extra bleed hole that isn't cov ered by the washer. The right bleed size will give us good low-speed damping without wallowing. As we hit bumps faster, the system still feels good, be cause before our bleed hole goes into V-squared lockup, the pressure building up lifts the washer and spring progres sively. This increase in orifice area keeps the damping force from rising at a V-squared rate. The harder we hit the bumps, the more the washer lifts up and the more orifice area we have for

the oil to flow through.

The result is a pretty good system-up to a point. We have good low-speed damping if we choose the bleed size right, and we can have good higherspeed damping by choosing the right spring and spring preload for the washer covering our extra orifice area. Dampers built this way were used on motorcycles for 25 years after about 1950.

There still was a problem, but it took time to discover it. Very early, damper engineers found that most of the damp ing force should act not as the wheel rises over a bump (compression stroke), but as it extends after the bump passes (rebound stroke). One cause is obvioustoo much compression damping tends to toss the machine up in the air. So early dampers were built with 90 per cent of damping on rebound, and only 10 percent on compression.

Motocross revealed something new. MX bikes need substantial compression damping to prevent bottoming on hard landings, but when more compression was built into dampers, riders com plained of harshness. When someone actually measured how fast MX damper pistons move over harsh bumps, the an swer was obvious. When the damper piston moved so fast, the variable-ori fice system was opening up complete ly-and then going into V-squared lockup. Damping force was rising to in finity over sharp bumps. This had been happening for years, but no one had been able to see it because suspension testing machines stroked the dampers too slowly to reveal the problem.

Since then, compression damping sys tems have been sized to prevent this situ ation-what suspension engineers call "orifice limitation." There was an imme diate benefit to pavement-going bikes as well; now, it was possible to use as much compression damping as was needed, without making the ride harsh. Compres sion damping is useful not only in ab sorbing ordinary bumps and preventing bottoming, but in controlling brake dive.

When one problem is solved, it never fails to reveal another. Modern dampers still have orifice systems consisting of a low-speed bleed orifice with a V squared characteristic, plus a main damping system with variable orifice area. Much art and science has gone into the problem of tailoring the variable-area orifice to a given bike's damping needs. The most common damping system cov ers the orifices with a stack of thin washers, whose flexibility takes the place of the spring described above. The washers are held down at the center by a nut, and oil pressure lifts their edges to flow through the holes covered by the stack (in some cases, washers are held down at the edge and lift up at the cen ter). By correct choice of the diameters and thicknesses of a stack of these wash ers, almost any curve of damping force versus velocity can be constructed. Also, the low-speed bleed orifice has become adjustable-that is what the clickers on modern dampers actually adjust.

Now for the new problem. As damper speed rises from zero, at first all the flow passes through the low-speed orifice. Be cause it has a V-squared resistance, damping force rises steeply. Before this gets out of hand, the main washer stack begins to open up and the curve of resis tance versus velocity settles down to a more linear rise. Everything is fine, right?

Nope. There are complaints. As roadracers exit corners, applying all the throttle their rear tires will take, the exact way in which the transition is made from low-speed damping orifice to main washer stack takes on magni fied importance. Where the V-squared of the low-speed orifice settles into the linear curve of the washer stack, there may be a cusp or inflection point on the resistance curve. This tiny bit of harsh ness or unpredictability upsets tire trac tion at a crucial phase. Suspension engineers have been busy with this one for the past three years. What's next?

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontVictory In the Desert

April 1998 By David Edwards -

Leanings

LeaningsShipping News

April 1998 By Peter Egan -

Letters

LettersLetters

April 1998 -

Roundup

RoundupHonda Super-Twin On the Way

April 1998 By David Edwards -

Roundup

RoundupGuzzi Makes Its Quota

April 1998 -

Roundup

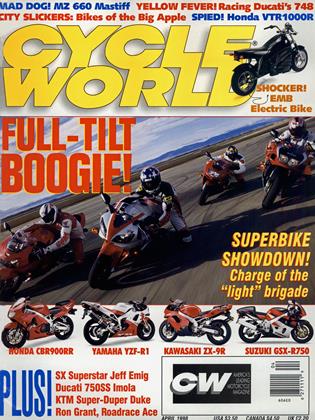

RoundupCharge of the Lightbulb Brigade

April 1998 By Andy Saunders