TDC

The coming of carbon fiber

Kevin Cameron

AT THE RECENT TOPEKA, KANSAS. AMA National, I was handed the fuel tank from a 250 Aprilia. Now, I'm used to the light-gauge aluminum tanks on Yamaha 250 roadracers. but I wasn't ready for the non-weight of a carbon-fiber tank. It was like being handed a balloon—nothing but bulk and color.

Kawasaki roadracers had fiberglass tanks in the period 1969-78, but fiberglass is heavy. Carbon fibers have a specific gravity of about 1.5 (this means they weigh 1.5 times more than an equal volume of water), while 'glass is more like 2.8. Where the lightest aluminum tanks weigh 34 pounds, and fiberglass tanks 5-8, that carbon tank was down around 2 pounds. The Aprilia's fairing and seat are similarly impressive—very thin and light. Wherever possible, compound curves are used to build stiffness into the shape. The flat surfaces in fashion when Kawasaki made those '70s fuel tanks (remember “breadloaf" tanks?) had to be made extra-thick to build adequate stiffness. By contrast, the balloonlike shape of the Aprilia tank is inherently resistant to buckling.

That same Aprilia has a structural carbon-fiber seat frame, built as a sandwich. To make best use of carbon, it must be loaded in tension or compression—not in simple bending. This is done by separating two layers of resin-impregnated carbon fabric by a foam core. Any bending load applied to the resulting sandwich must compress the fibers on the load side, and stretch those on the far side. The foam braces the carbon layers against buckling. Carbon's extremely high “spring constant"—its modulus of elasticity—makes it resist stretching very well indeed, so this foam-core sandwich technique results in extremely rigid, light parts. High-performance homebuilt aircraft make extensive use of this same technique.

Why no quantity production of carbon-fiber motorcycle chassis? Carbon-rein forced plastics have aging, corrosion and manufacturing problems. Sunlight degrades plastics, and because carbon fibers conduct electricity, they can participate in electrolytic corrosion when in contact with metals. This is why factorybuilt private aircraft are still riveted together out of metal sheet (rather like boilers), not molded out of much lighter, stifTer fiber composites. You may point out that fiberglass Corvette bodies last for years, but they aren't structural parts with human safety riding on their reliability. Carbon-fiber parts are being adopted in the aircraft industry, but it will be a while before composites are as well understood as are metals.

Choice of materials isn't just an engineering matter; there is prejudice to consider. Years ago, 1 was one of the idiots who believed that cars, motorcycles and airplanes had to be made of metal. Metal was God and I was a True Believer. Reality shook this faith. I saw streetbike vibration shatter metal fenders. When I went racing, I saw engine bolts fatigue in half. Crankcases and chassis cracked. Flywheels split. I wanted to know what was going on. so I got thick books on metallurgy and studied. I began to understand that metals are made up of masses of tiny crystals, somehow stuck together. As you would expect, there are defects in such a complicated and discontinuous materialdefects that stress-cycling can magnify into cracks. Further, the strengths of metals are far, far less than what you would predict, based upon the strengths of the interatomic bonds that hold them together.

On the other hand, when tiny, ultra-pure single crystals of metals are prepared, strengths near the predieted theoretical values are found. Even though real bulk metals don't develop their potential strengths, the technologies of alloying and heattreatment have given us excellent materials. The great thing about metals is that they bend rather than break; they can be hammered into useful shapes and. under stress, they usually fail in a slow and predictable manner. Metal helicopter rotor blades, for example, can operate for many hours after the first appearance of detectable cracks—a handy quality at five thousand feet. Ceramics can operate under stress at high temperatures. but when a ceramic turbocharger rotor fails, it fails instantly and completely—blammo. Metals forgive many of our design errors.

But who could resist the idea of those huge theoretical strengths? From that temptation comes the new technology of fiber-composite materials. Carbon or boron fibers are not single crystals, but they come far closer to single-crystal strengths than do bulk materials. Because the strength of these composites is in their fibers, best performance comes when the fibers are oriented in the direction of the applied stresses—not jumbled randomly. When you look at the “design" of a tree, with its grain flowing smoothly along the stresses of wind and weight, you realize what a waste metals sometimes are. With essentially the same properties in all directions, some of those properties are often unused.

Indeed, people who have worked with fiber composites—John Britten, designer/builder of the carbonframed Britten Pro-Twins racebike, for one—say the experience has made them downright suspicious of metals. How can all those little crystals stick together the way we want them to? Carbon composites are still expensive, but what is holding back their application more is the lack of inexpensive manufacturing technologies. Orienting those fibers means expensive techniques like hand lay-up or machine filament-winding. Britten's chassis are made by hand—so we can't all have one until there is a way to take the job out of John’s hands and give it to fast production machines.

View Full Issue

View Full Issue

More From This Issue

-

Columns

ColumnsUp Front

December 1991 By David Edwards -

Columns

ColumnsLeanings

December 1991 By Peter Egan -

Letters

LettersLetters

December 1991 -

Roundup

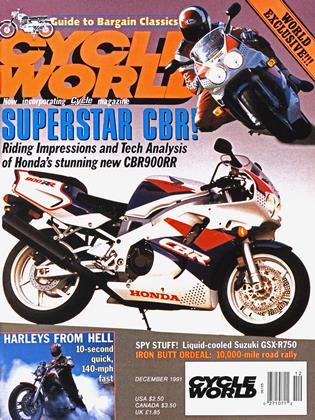

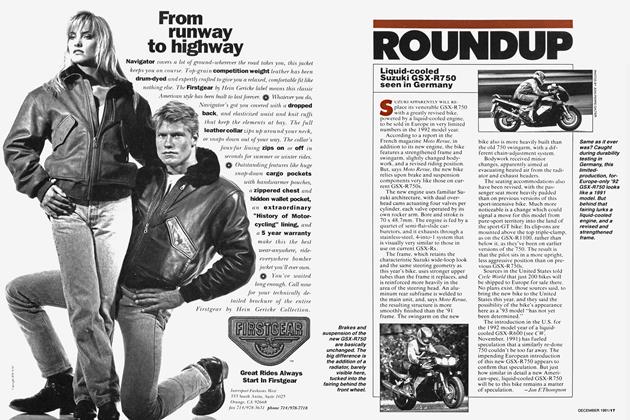

RoundupLiquid-Cooled Suzuki Gsx-R750 Seen In Germany

December 1991 By Jon F.Thompson -

Roundup

RoundupSuzuki Reinvents the Rokon

December 1991 By Jon F. Thompson -

Roundup

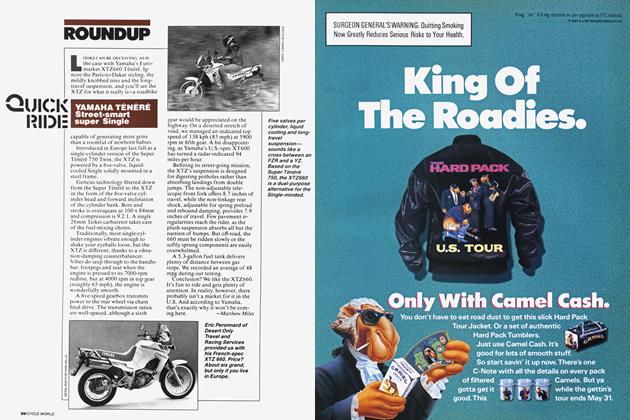

RoundupQuick Ride

December 1991 By Matthew Miles