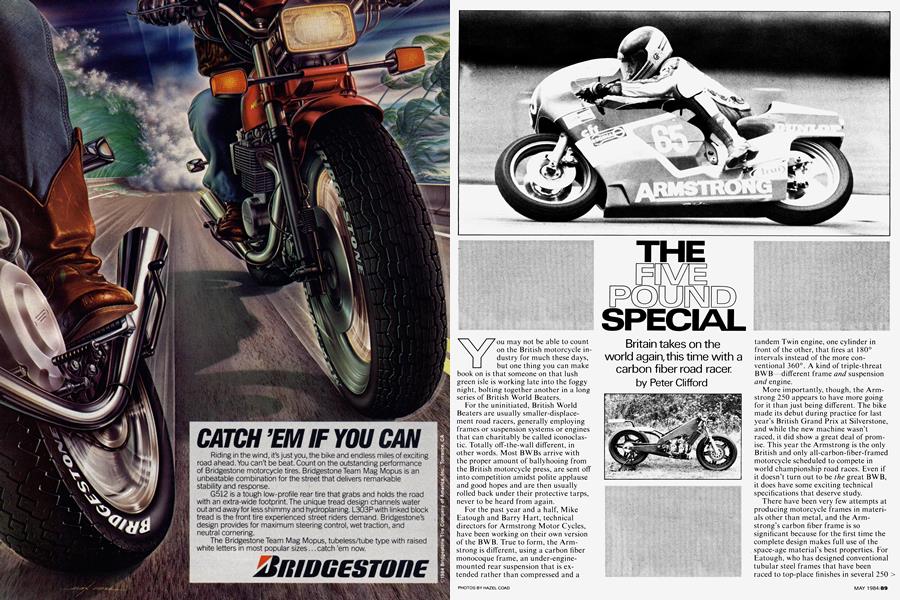

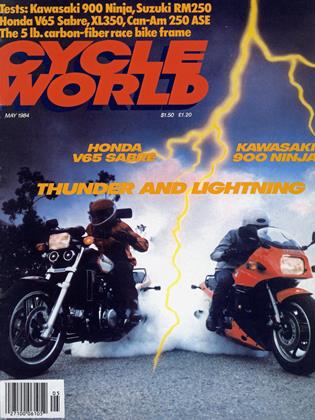

THE FIVE POUND SPECIAL

Britain takes on the world again, this time with a carbon fiber road racer

Peter Clifford

You may not be able to count on the British motorcycle industry for much these days, but one thing you can make book on is that someone on that lush green isle is working late into the foggy night, bolting together another in a long series of British World Beaters.

For the uninitiated, British World Beaters are usually smaller-displacement road racers, generally employing frames or suspension systems or engines that can charitably be called iconoclastic. Totally off-the-wall different, in other words. Most BWBs arrive with the proper amount of ballyhooing from the British motorcycle press, are sent off into competition amidst polite applause and good hopes and are then usually rolled back under their protective tarps, never to be heard from again.

For the past year and a half, Mike Eatough and Barry Hart, technical directors for Armstrong Motor Cycles, have been working on their own version of the BWB. True to form, the Armstrong is different, using a carbon fiber monocoque frame, an under-enginemounted rear suspension that is extended rather than compressed and a

tandem Twin engine, one cylinder in front of the other, that fires at 1 80° intervals instead of the more conventional 360°. A kind of triple-threat BWB different frame and suspension and engine.

More importantly, though, the Armstrong 250 appears to have more going for it than just being different. The bike made its debut during practice for last year’s British Grand Prix at Silverstone, and while the new machine wasn’t raced, it did show a great deal of promise. This year the Armstrong is the only British and only all-carbon-fiber-framed motorcycle scheduled to compete in world championship road races. Even if it doesn’t turn out to be the great BWB, it does have some exciting technical specifications that deserve study.

There have been very few attempts at producing motorcycle frames in materials other than metal, and the Armstrong’s carbon fiber frame is so significant because for the first time the complete design makes full use of the space-age material’s best properties. For Eatough, who has designed conventional tubular steel frames that have been raced to top-place finishes in several 250 grands prix, the carbon fiber frame was the answer to a search for light weight.

Although road racing Armstrongs (known in the U.S. as Can-Ams) have always handled well, they’ve been criticized for being overweight. Designer Eatough was under pressure to reduce weight as much as possible. The FIM

rule book sets the weight minimum in the 250 class at 198 lb.; complete with oil and water the Armstrong matches the limit. “I was looking to reduce weight,” said Eatough. “Formula One racing cars went from tubular construction through steel and aluminum monocoques to carbon fiber. I decided to skip the middle and go straight from steel tube to a carbon fiber monocoque.

“If you look at any article that is being made for maximum strength and minimum weight, from golf clubs to racing cars, everyone uses carbon fiber. It is the best material but the difficulty is learning to use it correctly,” said Eatough. To learn to use the composite materials that include carbon fiber and Kevlar as well as fiberglass, Eatough and his small engineering team read everything available on the subject and talked to all the suppliers and users of the materials they could find. Eatough feels that they were fortunate in being close to the British Aerospace and Lucas Aerospace works located in the north of England. Northern England has many firms involved in the production of composite material fibers and, as Eatough pointed out, this may well be because historically it has been the home of the textile industry and the composites are woven as fabrics before being molded into components.

Eatough started to design his new machine in November 1982. He already had Barry Hart's 250 tandem Twin, originally used as a replacement for the Rotax engine of similar layout. The strongest monocoque design would have been a single closed box but this would not allow access to the top of the engine and hence had to be modified.

To find out how strong structures such as swing arms and frame spars could be made, Eatough compared car bon fiber structures with existing components. He took a regular Arm strong box-section aluminum swing arm and cut out a section. He then made a carbon fiber spar of the same dimen sions. By bending and twisting first the aluminum and then the carbon fiber spar, Eatough was able to compare the two materials. He knew that the alu minum unit was strong enough and therefore a carbon fiber unit that could

A 180° tandem Twin has a unique balance problem, now solved.

match its resistance to twisting and bending would also be up to the job.

In this manner Eatough arrived at the method of frame production and also began to be able to predict mathematically the performance of his carbon fiber components. The frame and swing arm use six layers of composite material. The frame for example is made in two halves and then joined at the steering head. Each side has a separate mold. Into the mold are laid the sheets of fiber weave. The sheets are impregnated with resin so that there is none of the daubing of resin with brushes that is used in fiberglass. A square meter of sheet costs $85 so it is not difficult to see that the process is expensive.

The carbon fiber matting comes in many grades and the most crucial difference between one and another is the lay of the thousands of strands in the weave. All the strands may lie in the same direction but although that weave is tremendously strong in tension in the direction of the strands, it has no strength at all when pulled side to side. Other weaves have an equal number of strands running across side to side. The weave is then described as having its strands at 90 degrees. There are also weaves with one layer of strands at 45 degrees to the other. All three weaves are used in the Armstrong monocoque construction. Kevlar is also used. Kevlar is designed to “give” more gradually than carbon fiber when overstressed and hence is employed in high-stress areas.

The mold package is placed in an autoclave, a vacuum oven, to cure. Although precise details of the process are secret, the autoclave is heated to about 300° F for several hours. This cures the resin and produces a frame spar, which the Armstrong team calls a dish. The dish by itself has little strength, especially in torsion. To add strength in the lightest and strongest manner, an aluminum honeycomb is used. The aluminum is as light as foil but the short, straight sides of the honeycomb give it strength. It is cut to shape and stands in the already-molded dish.

continued on page 94

continued from page 91

The bottom of the aluminum honeycomb is coated in resin to bond it to the dish, then six more layers of fiber weave are placed across the top to seal the box. The unit is once more placed in the oven. The complete unit is an extremely

strong structure both in twisting and bending. In fact, the strength of the frame so impressed the Armstrong management that Hart and Eatough were given the OK to start work on a 500 GP bike using the same basic frame. The engine will be a Hart-designed across-the-frame two-stroke Triple, and the bike should see limited action this year.

The joint at the steering head, like the other load-bearing points such as the

engine mounts and the swing arm pivots, has fiberglass inserts. The inserts spread the load into the box sections.

The fiberglass blocks are made from compressed layers of fiber. The engine mounts in two places, at the top rear of the gearbox and from a specially cast cylinder head. The cylinder heads are special not only because of the mounting lug at the forward end but also because of the special inserts that form the combustion chambers. Normally combustion chambers are machined into the cylinder head castings. Hart employs separate inserts so that special combustion chamber designs can be tried more easily.

Failure in carbon fiber components may well be less likely than with steel, as cyclic loading of a steel component to only 40 percent of its ultimate tensile strength (UTS) may eventually cause failure, whereas carbon fiber will stand up to 80 percent UTS loading in cyclic stress. Eatough is also very aware of his responsibilities as a leader in his particular field. “I have overdesigned the machine to avoid the possibility of failure. When titanium was first used in racing machines it was used in some badly designed components and failed. The FIM banned it without understanding that it was the design that was at fault, not the material. I don’t want that to happen again.”

If the machine is crashed and darm aged it can be repaired; the machine pictured here has already had repairs done to its swing arm. “Damage to the monocoque is likely to be obvious,” said Eatough. This is because it is likely that the outer fiber will break first as these are the furthest from the neutral axis. “It is also possible to see if the layers of fibers have delaminated by pressing in with your fingers,” Eatough added.

Not relying on human inspection, Armstrong is developing the use of welltried acoustic techniques for checking frames. “By listening to the performance of a component when it is stressed in a jig, it is possible to determine its state of health,” Eatough stated. The technique uses the known sound emissions from a new component and compares it with the suspect example. The failure of a crashed component to produce the right noises at the right stresses should indicate its weakness.

The complete frame weighs 5 pounds, and the swing arm weighs another 5 pounds. This led to the machine being called the “Five Pound Special.” “The seat unit and the suspension unit also weigh 5 pounds each,” said Eatough. “One important thing is that the overall weight is kept down by the absence of rocker arms in the suspension or sub frames for the footrests.”

Although there are no rocker arms or linkages, which seem essential for a modern racing machine, the Armstrong design still provides a rising suspension rate. “The suspension rate rise is quite surprising,” reported Eatough. “It is more than you would expect from looking at it, and the angle between the unit and the swing arm changes as it moves.”

Few motorcycles have the suspension unit mounted under the engine, and the Armstrong is a real breakthrough in that it uses a special unit in extension instead of in compression, as is conventional in twin-shock, cantilever or rocker-arm systems. Eatough was fortunate in working for Armstrong, a company that supplies suspension units to various automobile companies. They were able to produce the special unit, which is pulled from one end and is held in place by the shock body.

The unit’s body is mounted by two machined brackets onto the bottom of the engine. The unit is allowed to pivot in its mounting and is pulled on by the swing arm.

The swing arm is a beautifully molded piece, triangular in shape and very strong. The drive chain runs through a tunnel in the arm and this, in the design stage, was a worry to Eatough. “We feared that the chain would flail away at the material but it hasn’t happened.”

The lack of problems so far has been amazing: The machine had only been test ridden twice before it was unveiled to the public during practice for last year’s British Grand Prix. Although the team has been hampered by poor weather, more testing has been done but no problems have yet been found in the design.

The secret of the Armstrong’s remarkably low weight goes further than the main frame components. The fairing is carbon fiber, light and strong. Even the brake lever is compressed fiberglass.

There would be little point in reducing the weight of the machine if the wheels, as parts of the unsprung weight, remained heavy. The unsprung weight of the wheels and accompanying hardware must be reduced as the weight of the complete machine is reduced to give the suspension a reasonable chance to cope. The Armstrong will eventually use wheels made of carbon fiber but for the moment they are spun aluminum with cast magnesium hubs. The spun wheels were developed by Tony Dawson under the name Astralite. The Armstrong’s are special, using the Dawson concept but with thin-gauge material, an extra lip around the rim for strength and Armstrong hubs. They weigh only 5.75 pounds bare as compared with 1 1 pounds for the same sized Campagnolo assembly. The machine is pictured with 1 8-in. wheels fore and aft but will be raced with a 16-in. wheel in the front.

The rear brake uses half of a Brembo caliper bolted to a specially machined aluminum plate. The front wheel is stopped by twin Brembo calipers and floating aluminum discs. The front forks look like Marzocchis but although they started their life in Italy, the insides are all Armstrong.

By testing the fork legs in their own rigs, the Armstrong shock absorber development engineers were able to study their limitations. The stock fork legs suffer from severe sticking when under side loads such as in a braking situation. The internal bearings were redesigned to get rid of the stickiness and the damping system was also improved to give compression and rebound damping. Front forks, though, are the next thing to come under the Eatough eye. Forks as we know them will soon be replaced if the Armstrong man progresses as he intends.

The powerplant for all this innovative hardware is a twin-cylinder disc-valve 250 that started life as a 350 and was raced through 1982 by Jeff Sayle, its highest finish being third at the French round. The fact that Sayle didn’t improve on or match that performance later in the year could be because the factory started to concentrate on developing a 250 as the end of the 350 class was in sight.

The 350 had a bore and stroke of 64mm x 54mm. The 250 is square at 54mm x 54mm. The engines share the same crankcases, and unlike the Rotax, these are split horizontally. This allows the use of three crankshaft bearings.

The ball bearings are placed either side of the crank flywheels and the third outside the primary drive gear. The primary drive gears are on the left side of the engine with the steel disc valves and the carbs on the right. The primary drive gears run in an oil bath common with the gearbox, providing good lubrication to the two crankshaft bearings on either side of the gears. The bearings on the disc valve ends of the crank are lubricated by the gas/oil fuel mixture in the normal fashion.

In a further display of weight watching, the latest engine cases are made in magnesium as is the cylinder head. Cylinders are aluminum, and experimental cylinders are being tested with an exhaust power-valve mechanism.

Unlike the Rotax or Kawasaki tandem Twins, the Armstrong now has a 180° firing interval. The other engines, and the 350 Armstrong and early 250s, had 360° firing, which meant that the pistons rose and fell together. Parallel Twins like Yamahas have 180° firing so that one piston is at top dead centre while the other is at the bottom. In Hart’s experience, a 360° Twin like a Rotax requires six or seven more horsepower to lap a circuit in the same time as a 180° Twin like a Yamaha. Hart suggests that the reason for this lies in the rate at which a transmission system can pass on a power input. Smaller, more even power impulses will pass through the system more readily than can half the number of impulses that are twice as strong. Some of Hart’s predictions about 180° engines have already turned out to be correct. He thought that the engine would require different porting and exhaust pipes in its new form and this has proven so.

In back-to-back tests between similar Armstrong 250 engines, one with 180° cranks and one with the 360° setup, the former has shown a marked ability to pull out of corners quicker, so Hart’s assertions about the ability to impart power may very well be correct.

To build a reliable 180° engine Hart had to solve the configuration’s inherent balance problem. The cranks are counter-rotating and geared together. When such an engine’s pistons rise and

Failure in carbon fiber components may be less likely than with steel.

fall together, the counterbalance weights on each crank swing in opposition and cancel each other. But with one piston up as the other is down, such as in the Armstrong system, the counterbalance weights are both forward of the crank centers at the same time and then both behind: This inbalance shakes the engine fore and aft. Armstrong’s answer to the problem is still a secret, but the problem no longer bothers Hart. He is more concerned with finding good quality pistons and redesigning the cylinders, which started life as 350 cylinders with different cores.

Finding a suitable ignition system that would fire at 180 degrees with the correct advance curve was a major headache and because the two cylinders do not now work together, the primary gears, which were gear cut, must now be ground to withstand the added stresses. Although sorting the 180° engine has taken time Hart can take credit because Kawasaki failed to do what he has achieved; their original tandem Twin was a 180 but shook itself to pieces until they converted it to a 360° firing pattern.

Hart does not make outlandish power claims for his 250 but says quite simply that a genuine 70 bhp with the correct spread of power coupled with the machine’s light weight should prove more than competitive. Nineteen eighty-three was intended as a development year for the new engine as well as the chassis. With luck 1984 will show that the time invested on the drawing board and in the dyno room was well spent. Eatough and Hart don’t intend for the Armstrong to be another British flash-in-thepan. They’re shooting for a grand prix win this year. S

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontMy Farewell Address

May 1984 By Allan Girdler -

Cycle World Letters

Cycle World LettersCycle World Letters

May 1984 -

Departments

DepartmentsCycle World Round Up

May 1984 -

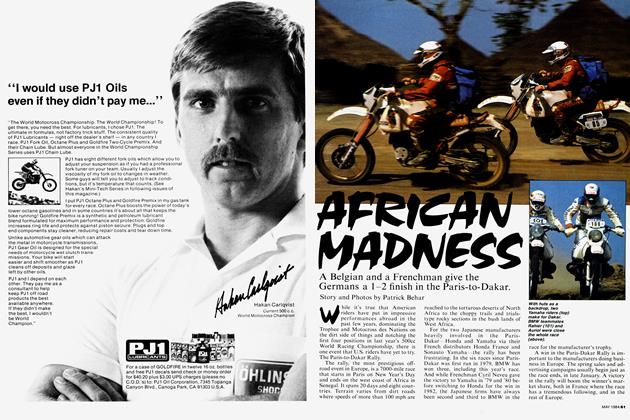

Features

FeaturesAfrican Madness

May 1984 By Patrick Behar -

The Friction Clutch

The Friction ClutchHow Motorcycles Work 3

May 1984 By Steve Anderson -

Competition

CompetitionOne Bike Fits All

May 1984 By Allan Girdler