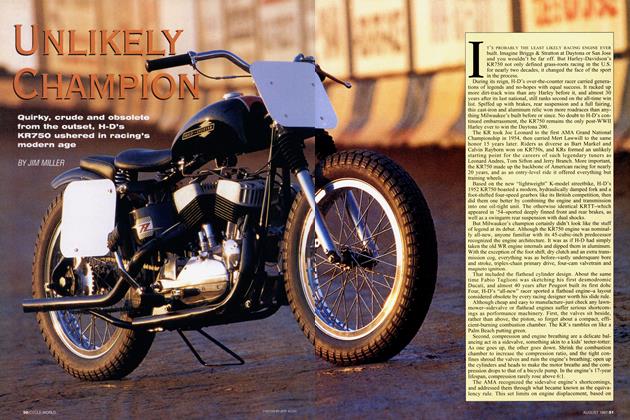

THE ELEVATOR SYNDROME

Why Shaft-Drive Bikes Jump Up and Down and What Can Be Done About It.

Jim Miller

Like death and taxes, the drive characteristics of shaft-drive bikes are considered inevitable. Twist the throttle and the back end comes up. It's the price you pay for the clean running and low maintenance of a shaft.

The first time we'd ask about it, we'd get the response, "It's 'cause the pinion's trying to climb up the ring gear. They all do it.” We’d all nod stupidly and go on our way, trying to figure that one out.

The fact is, they don’t all do it, at least not to the same degree. Most road tests of current shaftdrive bikes discuss the tendency in a para-

graph, then go on to note that it’s “well controlled” in this particular model. Okay. How?

There are a couple of clues. If you start up a shaft-drive bike, put it in gear, apply the front brake and let the clutch out, the back end comes up like a cork in a bathtub. Do the same thing, only this time apply the rear brake. The en> gine stalls. But the back end stays down. What’s the difference? Forget ring and pinion. In one case the rear wheel moves, in the other it doesn’t.

Since the late 1950s motorcycles have all had the same basic rear suspension; a swing arm, with its movement controlled by one or two shock absorbers with concentric springs. The rear wheel connects to one end of the swing arm and the rest of the motorcycle to the other. All the force applied to the frame by the rear wheel is transferred from the axle through the swing arm. Simple. And effective, to a point.

The major drawback is that in most cases, the swing arm slopes downward at a slight angle from the pivot to the axle. While the force that drives the motorcycle forward is essentially horizontal, the swing arm is not.

The result can be shown with a simple piece of paper. Fold a sheet of paper in half, crease it and then open it up. Lay it on a table with the crease up. If you push toward the crease from either end of the paper, the center of the sheet goes up as the sheet slides along. Do the same thing with a flat sheet of paper and you simply push it off the table.

When the force is applied to the folded sheet of paper, it splits into horizontal and vertical components. The horizontal component acts to move the paper forward. The vertical component acts to move the paper upward.

A 20 lb. force doesn’t actually split into 16 lb. forward and 4 lb. upward. It’s not that simple. (Now you remember why you hated physics.) The horizontal and vertical components form the base and height of a right triangle, with the paper as the hypotenuse. It seems odd, because the components are greater than the force applied, but that’s physics.

Getting back to motorcycles, let’s say we have a bike with a 17-in. long swing arm mounted at a 7° angle to horizontal, Figure 1. (That’s about the same as a BMW.) In this case, a 200 lb. horizontal

force at the rear axle produces about 24.5 lb. of vertical force at the swing arm pivot. If this doesn’t sound like much, remember you can apply near 200 lb. by pushing on the axle.

Long about this time you’re probably thinking, “okay buffalo breath, how come it doesn’t happen on a chain-drive bike?” Well it doesn’t, you guessed it, because it’s got a chain.

In the case of a chain-drive motorcycle, the same horizontal force at the axle produces the same vertical force at the swing arm pivot. But here there are two other pieces involved—the chain and rear sprocket.

The typical chain-drive motorcycle runs a rear sprocket one-third to onefourth the diameter of the rear tire. This means that the same 200 lb. force at the rear tire requires 600 to 800 lb. of force at the sprocket. (Gears, sprockets and wheels can either multiply force or distance traveled, not both. Don’t talk to me, talk to Isaac Newton.) The kicker is that this force at the sprocket is added to the force at the rear tire patch when it’s applied to the axle. This means that 200 lb. at the rear tire patch is increased to 800 to 1000 lb. at the rear axle, depending on the size of the rear sprocket.

For example, if we have a sprocket one third the diameter of the rear wheel, 200 lb. at the tire patch requires 600 lb. at the sprocket. This produces 800 lb. at the rear axle. With the same 17-in. long swing arm and the same 7° angle, there are 98 lb. of vertical force at the swing arm pivot. So four times the force means the back end of a chain-drive bike comes up four times as fast, right? No.

With a chain-drive motorcycle, this lift is counterbalanced by a second force acting in the opposite direction. It should be no surprise that this force is created by the chain.

This counterbalancing action is still created by the angle between the swing arm and the direction of the force applied. Except in this case, the force is applied by the

tension of the top row of the chain.

I’ll use the same wheel and swing arm as before, only this time I’ll add a chain (it’s easy to do on paper), running at a 10° angle to the swing arm and a sprocket onethird the diameter of the rear wheel. This combination will still give us 800 lb. at the rear axle and 98 lb. of lift at the swing arm pivot.

But now we’ve got a 600 lb. force (the top row of the chain) pulling on the sprocket.

Just as in the case with the driving force, this one can be split into horizontal and vertical components. But here, neither the direction of the force nor the swing arm is horizontal, so it’s a bit more complicated. It has to be done in two steps.

The angle between the swing arm and the chain is 10°. If we draw a horizontal line through the angle formed by the chain and the swing arm, we can make two 90° triangles, one with an angle of 3 °, another with an angle of 7. The combined height of c both of these triangles is the vertical force acting on the swing arm, Figure 2.

The smaller triangle gives a result of 31.5 lb. of vertical force, the larger one, 73.5, for a total of 105. This force acts to pull the swing arm up at the axle. This offsets the force at the swing arm pivot and the chain-drive bike squats.

A couple of words of explanation here. The only reason this counterbalancing force affects a chain-drive bike is that there is a flexible joint (the swing arm pivot) between where the force originates, (the countershaft sprocket) and where it winds up (the rear sprocket). This same* force is there on a shaft-drive bike, created by the pinion and ring gears. But it’s busy trying to bend the swing arm. If the countershaft sprocket were moved to the swing arm pivot the force would still be there but it would also spend its time trying to bend the swing arm and have no effect on the * rear suspension.

The second point is that this is also a somewhat extreme example, at least in the

case of chain-drive machines. Most of these will run a longer swing arm, usually about 20 in., at a much shallower angle. Despite that, the relationship between the drive force and chain force still holds. For a number of reasons (the favorite being an increase in cornering clearance when the rider overcooks it into a corner and backs off the throttle) squat under power is considered A Good Thing. Consequently, it’s designed into the rear suspension on chaindrive bikes.

Getting back to shaft drives, there are a number of ways to control the drive shaft reaction. Obviously, making the swing arm horizontal will eliminate it. But at what point should it be horizontal?

Any weight added to the machine will compress the rear suspension, so having the swing arm horizontal at the unladen ride height will only make the swing arm less than horizontal when the bike is loaded. This will make the bike squat under acceleration. (Trust me on this one. The force reverses direction when the axle goes above the swing arm pivot.)

Another problem is that a horizontal swing arm limits suspension travel. Most bikes require a slight downward angle on the swing arm to increase fender/frame clearance at full compression. The solution here is to shorten rear suspension travel, which is unacceptable for obvious reasons.

One way to reach some compromise with swing arm angle is to consider the bike’s intended purpose.

For years a shaft-drive bike meant touring and a shaft-drive touring bike meant BMW. One of the prerequisites for a touring bike, at least for the American market, was the ability to carry the full touring regalia: saddlebags, fairing, trunk and maybe a passenger. Although the swing arm starts out at a fairly steep angle, a fully loaded BMW has its swing arm close to horizontal. Hence, little or no drive shaft reaction.

Unfortunately, when the company changed its image in the mid-70s it didn’t change its chassis. The R90S came with 900cc, 70 horsepower, Dell’Orto carburetors, the same steep swing arm angle and a hefty dose of drive shaft reaction.

The R90S points out that a sport machine requires a different set of priorities. Most of these bikes are designed to handle one person with a minimum amount of baggage. Yamaha’s 750 Seca is a good example of a shaft-drive sport bike, and has far less drive shaft reaction than the R90S. This bike was designed from the ground up as a sport bike, and the swing arm is much closer to horizontal than it is on the R90S.

Another way to get the swing arm closer to horizontal is to make it longer. If there is a 2 in. vertical difference between the axle and the swing arm pivot, stretching this >

drop out over 20 in. of swing arm length gives a smaller angle than spreading it over 17 in. The limits here are determined by longer engines on shaft-drive bikes than those on a chain-drive.

On a shaft-drive bike, the output flange on the transmission determines the location of the U-joint and swing arm pivot. On a transverse engine, like the Yamaha Seca, Honda CB900C or one of the Gmodel Suzukis, there is an additional gear set added to the transmission to turn the power output through 90“. This adds to the overall length of the engine/transmission. The situation is similar with longitudinal engines, a la Honda Gold Wing, Moto Guzzi or BMW. Here, all of the powertrain components are in line, so the crankshaft, clutch, transmission shafts and the output flange all combine to produce a narrow, but fairly long, package.

In both cases, in order to keep the wheelbase to less than that of a boxcar, the added length must come out of the swing arm. The difference can be minimized. For example, the Yamaha 750 Virago has a swing arm only 3A in. shorter than its chain-drive stablemate, the XV920. Moto Guzzi mounts the swing arm on the V50 to the back of the transmission, rather than to the frame, to allow for a longer swing arm.

In addition to the swing arm, there are a number of other factors that influenced the drive shaft reaction. One of these is obvious—the shocks.

Shock absorbers control the movement of the rear suspension in both directions, up (compression damping) and down (rebound damping). Increasing the rebound damping on the rear shocks will reduce the tendency of the rear suspension to jack up. But the benefits here are limited.

Shocks are built with a closely controlled relationship between the compression and rebound characteristics. Increas-

ing the rebound damping will also decrease the speed at which the rear suspension recovers from a bump. Too much rebound damping will cause the rear suspension to pump down over a series of bumps. The only way to control this is to increase the spring rate and compression damping, which puts us back to 1960 with rock hard suspensions and kidney belts.

For the individual rider there is a glimmer of hope here. Current suspensions are moving more and more toward owner adjustability. The result is the same as determining swing arm angle by considering the bike’s intended purpose. But here, the owner knows the intended purpose, it’s not determined by the marketing department’s consideration of the 95th percentile buyer. If the owner uses the bike for short jaunts to and from work on glasssmooth roads, he can crank in all the rebound damping he wants, knowing he can change it again for some Banzai riding on Sunday.

Along the same lines, bikes are moving toward air-adjustability on rear suspensions. This allows the rider to tune the spring rate on the bike. It also allows him to select the ride height, and thus the swing arm angle. Again, no compromise about the average rider.

What about the new linkage type suspensions? Don’t hold out a whole lot of hope here. These suspension systems, like the Pro-Link introduced to the street on Honda’s GL500, use a series of levers and bellcranks to make the suspension more progressive. They are tuned to produce a very supple ride during the first few inches of travel, which is precisely where the drive shaft reaction is most noticeable.

There is, however, another innovation that’s surfaced in the last couple of years that offers a great deal of promise. Antidive. (Suspension interactive braking for those of you infatuated with engineerese.)

These systems use the hydraulic pressure (or in Honda’s case, the torque reac-

tion) of the front brake to increase the compression damping of the front fork. The technology is the same, it’s just a matter of applying it to the damping on the rear. With the increasing popularity of shaft drive, it may only be a few years before one of the manufacturers adds some form of anti-rise or anti-squat (suspension interactive drive?) to the rear of a shaft or chain-drive bike.

I’ve pointed out several ways the reaction can be controlled. Can it be eliminated? With today’s rear suspension designs, no. As long as the swing arm acts through a single point (okay, it’s a line) on the frame, the drive will always have some effect on the suspension.

There are suspension designs that can eliminate it. During the early Seventies, Kawasaki experimented with a two link, parallel swing arm arrangement that potentially would have eliminated the driving force’s effect on the suspension. The system showed some promise, but was dropped due to the extra complexity and weight it added to the machine.

Recently the idea has been resurrected with the BMW Futuro. This bike uses what appears to be a conventional swing arm suspension, with one significant difference. The rear hub is not rigidly bolted to the swing arm, but is located by the rear axle. The rear hub is kept from pivoting around the axle by a torque link. This arrangement is much like the full-floating rear brake often used on motocross machines. Any driving reaction is fed back to the frame through the torque link, not the swing arm.

Both of these designs change the path of the drive force from a triangle to a parallelogram. In simple terms, the push on the swing arm is balanced by the pull on the torque arm. This should, in theory, eliminate the jacking effect. From there it’s just a matter of working out the proper geometry.

Cheeze, it was a whole lot simpler with the pinion climbing the ring gear. S