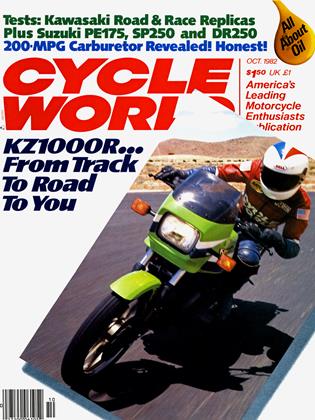

All About Oil

Motorcycle Engines Run Hot and They’re Hard on Oil, but That’s No Reason to Panic. It’s Not as Bad as You Think.

John Ulrich

There’s more to oil than pouring it out of a can and into a motorcycle. Before he can even get that far, a rider is faced with decisions. Is it better to run 10w-40 or 20w-50 or SAE 40 or what? Is synthetic better than mineral oil, and if so, is it enough better to be worth the extra price? How often should oil be changed in a motorcycle engine? What about oils that are a mix of synthetic and mineral bases? What brand of oil is best? Is there any advantage to buying trick motorcycle oil instead of whatever is on sale at the local parts store?

Good questions all. To complicate matters, not all the questions have simple answers. But after talking to representatives of motorcycle manufacturers, contacting oil company researchers and conducting our own tests, we’re ready to address the questions listed above and others discovered along the way.

Oil as encountered by motorcyclists is labeled with a grade, such as SAE 20w-50 or SAE 40, referring to the viscosity, or thickness of the oil. Viscosity is the technical term used to describe a fluid’s resistance to flow. Molasses is a high viscosity fluid; water flows easier, so it has less viscosity. If an oil has two viscosity numbers, as in 20w-50, it’s a multi-grade oil. The w in 20w-50 stands for winter, and the 20 means that a 60cc sample of the oil takes between 12,000 and 48,000 sec. to flow through the standard orifice (similar to a carburetor main jet) in a Saybolt Viscosimeter at 0°F. The 50 in 20w-50 means that the 60cc sample takes between 85 and 1 10 sec. to flow through the orifice in a Saybolt Viscosimeter at 210°. A singlegrade SAE 20, 30, 40 or 50 is tested only at 210°. A single-grade SAE 5w, lOw, 15w or 20w is tested only at 0°. The grades and test procedure are sanctioned by the SAE (Society of Automotive Engineers), and the exact numbers obtained by testing a specific oil are referred to in terms of SSU (Saybolt Seconds Universal) or SUS (Saybolt Universal Seconds).

There are four possible SAE w ratings for oil, and all refer to an oil’s flow rating at 0°. A 60cc sample of a 5w oil takes less than 6000 sec. to flow through the orifice, so has an SUS rating of less than 6000. A lOw oil has an SUS of 6000 to 12,000; a 20w has an SUS Of 12,000 to 48,000; and a 15w is a 20w with an SUS of less than 24,000.

There are also four possible SAE regular (non-winter) grades of oil, referring only to the SUS at 210°. Those grades are 20 (SUS between 45 and 58); 30 (SUS between 58 and 70); 40 (SUS between 70 and 85); and 50 (SUS between 85 and 110).

At one time the SAE also recognized grades of 60 (SUS between 110 and 160) and 70 (SUS over 160) but those grades ceased to be officially recognized about 30 years ago. Harley-Davidson oils labeled 105 and 140 and sold until last year were SAE 50 and grade 60 oils; the numbers on the can were the actual SUS test numbers. In other words, a 60cc sample of HarleyDavidson 105 oil took 105 sec. to drain in the Saybolt Viscosimeter at 210°.

There are two grading systems, winter and regular, because oil changes thickness at different temperatures. The hotter an oil gets, the thinner it is. The cooler an oil gets, the thicker it is. Straight SAE 40 may work fine during hot summer months, but an engine filled with SAE 40 may not start after being parked overnight in a snowstorm.

Conversely, a single-grade oil thin enough to earn a 5w rating might allow easy starting after a night in a snowbank, but would be so thin at 210° that it could not keep metal bearing surfaces apart. The resulting metal-to-metal contact could lead to increased wear or even seizure.

The ability to keep bearing surfaces apart is called film strength, and it is directly related to viscosity. Thicker oils have better film strength, and film is what engine lubrication is all about. The ideal is hydrodynamic lubrication, in which a film of oil covers every moving part and the moving or stationary surface it works against. When a film of oil coats a crankshaft journal and a plain main bearing, the crankshaft journal doesn’t touch the main bearing. Instead, the two oil films slide against each other.

The failure of hydrodynamic lubrication is boundary layer lubrication. Look at a cylinder wall or the face of a piston ring through an electron scanning microscope and the surfaces aren’t perfectly smooth but present an alarming metalscape of mountain crags and deep crevasses. Hydrodynamic lubrication puts films of oil between the high spots of the cylinder wall and the piston ring face. Boundary conditions exist when the microscopic peaks of the cylinder wall touch the peaks of the corresponding ring face. This contact is apt to occur when the piston stops and changes direction under pressure, as at the top of the compression stroke, and the result is cylinder and ring wear.

If the films between ring and cylinder wall are too thin at that point, more than just the peaks of each surface will contact, greatly increasing wear, or, in extreme cases, causing seizure. When pistons seize, it is because the films on the piston and on the cylinder were overcome by heat (remember, the hotter an oil gets, the thinner it gets) and pressure. This allowed metalto-metal contact beyond that encountered in boundary layer lubrication.

Thicker oil, all other things being equal, has higher film strength.

The obvious question, then, is how to get an oil thin enough for cold-weather starting and thick enough to provide adequate film strength at warm-weather running temperatures?

One solution is to use one grade of oil for warm weather and another for cold weather. But cold snaps can end or interrupt warm weather suddenly, leaving a rider stuck with oil that is too thick. Even if the engine starts, its problems may not be over. Thick oils take longer to reach critical moving parts after a cold start. Thick oils also increase oil pressure, and revving an engine with thick oil immediately after a cold start may blow out oil seals or oil filter housing O-rings.

Which is where multi-grade oils come in. A multi-grade oil is basically an oil thin enough to provide easy starting and fast flow to engine parts in cold weather, with polymers added to make the oil thicker at higher temperatures. Polymers are longchain plastic molecules that can be likened to a live spider when hot and a dead, legs-curled-underneath (as when shot with contact cleaner) spider when cold.

The addition of polymers makes it possible for an oil to qualify as a 20w at 0° and as a grade 50 at 210°. As the oil is heated, the polymers unfold, making the oil thicker than it would be without polymers.

This does not mean that the oil physically gets thicker. All oils thin as they are heated. But a multi-grade oil with polymers thins less than an equivalent singlegrade oil without polymers. At 0°, a single-grade 20w oil and a multi-grade 20w-50 may have identical SUS numbers. But at 210° the 20w oil will be dramatically thinner than the 20w-50 oil.

Carrying this further, at 0° a grade 40 oil is much thicker than a 20w-50. But at 210° a grade 40 oil is much thinner than a 20w-50. Single grade oils are thinned more by heat than are multi-grade oils. Adding polymers makes an oil’s viscosity more stable over a range of temperature. That’s why a 20w-50 multi-grade oil is thicker at 210° than a 20w or a grade 40 oil. Because the 20w-50 is thicker, it has superior film strength—all other things being equal.

Unfortunately, all other things are not equal. There’s more to oil than polymers and grades. Engine oils start with base stocks, which are refined from crude oil and classified by their characteristics, including viscosity (or thickness), flash point (the temperature at which the oil will ignite if exposed to flame, but only as long as the flame is present), carbon content, and pour point (the lowest temperature at which the oil is still liquid).

Base stocks are often blended together, and what combinations are used affect the final characteristics of an engine oil. If an oil has a low flash point, oil on the cylinder walls will ignite and burn away, and the engine will use more oil and suffer more cylinder, ring and piston wear. But a highflash-point oil may cost more.

Thicker base stocks have more carbon content, and carbon content improves film strength—but also increases combustion chamber, piston dome and valve stem deposits.

Setting out to make a 20w engine oil, a company could use, straight from the refinery, a low-carbon-content base stock with an SUS number falling within the range for that grade, and accept its strengths and weaknesses. Or the company could blend a thinner base stock with a thicker, high-carbon-content base stock and produce a 20w oil with exceptional film strength and a tendency to increase engine deposits. Or the company might blend a thin, low-carbon-content oil with a slightly thicker oil that has a little more carbon content, the final product still qualifying as an SAE 20w but being a compromise between the other two examples used.

The oil company could take any of the three SAE 20w oils described above and add polymers until that oil had an SUS number between 85 and 110 at 210°, stamp 20w-50 on the can and sell it.

Looking at the cans on a store shelf, a motorcyclist can’t tell which oil is thickest, let alone best for his bike. One of the 20w-50 oils might actually be at the bottom of the SUS number range in each category, say, 12,030 at 0° and 87 at 210°. Another might be at the top of the SUS number range, say, 47,689 at 0° and 109.7 at 210°. That’s a big difference in viscosity, yet both can be labeled 20w-50.

Even if the rider could tell which oil was thicker, there are other questions considering carbon content. A racer who frequently rebuilds his bike’s engine would probably get the best results from the oil with the most carbon content, since that oil would offer the best film strength and wear protection—all other things being equal. But used by a sedate touring rider, the same oil might cause accelerated carbon buildup, requiring a premature valve job and decarbonizing to restore performance.

Then there are additives, chemicals blended into the oil to deal with problems. Some additives discourage oxidation since heated oil tries to combine with oxygen, and, given enough time and temperature, turns into a black Jello-like substance. Other additives decrease the pour point of an oil, keeping it liquid at lower and lower temperatures. Some additives work to prevent camshaft scuffing immediately after cold startup, before pressurized oil reaches the cam lobes. Other additives prevent metal-to-metal contact under extreme pressure in situations that would otherwise fall into the boundary layer lubrication category. Some additives inhibit rust and corrosion. Others, called detergents, keep carbon particles suspended in the oil until it’s drained. Still other additives reduce oil foaming, since a mix of oil and air doesn’t travel well through an oil pump.

The use of other additives is highly controversial. Companies selling oils containing Teflon, graphite and molybdenum disulphide say that those additives reduce wear and friction. Companies selling oils without these additives say that Teflon can oxidize and create ammonia in the oil; graphite conducts electricity, so oil deposits on spark plugs become conductive and cause shorts; and molybdenum disulphide leaves abrasive silica deposits in the absence of oil.

The best additives and the ideal amount of those additives depend upon the engine the oil will be used in. One engine may routinely reach 320°, while another never tops 220°. The hotter-running engine needs an oil with more anti-oxidation additives, since oxidation increases exponentially above 230°.

We’ve seen that the presence of polymers, the selection and blending of base stocks, and the collection of additives— often referred to as the additive package—greatly influence oil’s performance. But so far we’ve only considered oil as it comes from the can, when it’s new. What happens after it’s been inside a motorcycle engine for a few thousand miles?

The long-chain plastic molecules, or polymers, used in multi-grade oils can be chopped up into small pieces under certain conditions, and, as the polymers are chopped up, the oil gets thinner.

This process is called shear, and motorcycle transmission gears are a prime cause of shear. The combination of high normal running temperatures, high horsepower output per displacement and the use of engine oil to lubricate the transmission produces the toughest environment for oil in terms of shear.

It is possible for a 10w-40 oil to shear down and become a 10w-30 between oil changes. It’s also possible that the change in viscosity due to shear could reduce film strength enough to cause increased wear or more serious engine damage.

Ideally, a multi-grade 20w-50 engine oil would still be a 20w-50 after 3000 mi. but such “stay in grade’’ performance is rare.

Resistance to shear, or shear stability, can be measured in laboratory tests which result in a Shear Stability Index (SSI) number. In a typical test, oil with the mostshear-resistant polymers will produce an SSI of 10, meaning that the oil is 10 percent thinner at the conclusion of the test, as measured in SUS at 210°. In the same test, oil with the least-shear-resistance polymers will produce an SSI of 40-50, meaning that the oil is 40-50 percent thinner after the test.

A 10w-40 oil with an SSI of 40 could be> expected to shear down into a 10w-30 within 2000 mi. in a motorcycle engine.

A 10w-40 oil with an SSI of 10 could also shear down into a 10w-30 after 2000 mi. in a motorcycle engine, if that oil started with borderline 10w-40 SUS numbers, for example 71.5 at 210°.

Adding polymers is not the only way to increase the temperature stability of an oil. Another way is to blend certain synthetic base stocks with petroleum base stocks, or to use 100 percent synthetic base stocks.

Synthetics, like petroleum oils, are basically hydrocarbons. Synthetics can be made from any hydrocarbon sources, including petroleum oil, natural gas, animal bone marrow, animal fat and coal. But while refined petroleum oils retain their natural molecular structure, the molecular structure of the hydrocarbons used in synthetics has been altered to produce specific characteristics.

Besides improving the temperature stability of an engine oil, adding synthetic base stocks (or using synthetic base stocks exclusively) can increase the molecular density of an oil film, providing more resistance to metal-to-metal contact under extreme conditions. Synthetic base stocks can also improve an oil’s flow characteristics at extremely low temperatures, as found in arctic climates. Synthetics are oxidation resistant and so, in theory, can be used for more miles between oil changes.

But just as there are varying qualities of polymers, there are varying qualities of synthetics. Not all synthetics are the same, and good synthetics, like good polymers, are very expensive. Most synthetic base oils require the use of some polymers to meet the SUS requirements for multigrade oils, and the quality of the polymers again influences the SSI of the oil. There are 100 percent synthetic motorcycle oils on the market which have an SSI of 40. There are also 100 percent synthetics which won’t mix with petroleum oils, so a rider caught a quart low in the boondocks could be in real trouble.

Oil cans or bottles don’t carry SSI and SUS numbers, base stock compositions or additive package formulations. But besides the SAE viscosity grade, there is an American Petroleum Institute (API) performance rating for engine oil. To earn a certain rating, oil must pass tests defined by the American Society of Testing and Materials (ASTM). Representatives of the API, which is essentially an oil industry technical trade group, and the SAE, essentially an automotive industry technical trade group, meet and work together on ASTM committees to establish test procedures and pass/fail criteria for both SAE viscosity grades and API service ratings.

The toughest API service rating is SF, and to carry the SF rating oil must pass a series of dyno tests. One test measures an oil’s ability to prevent valve train rust, and involves running a 425 c.i. Oldsmobile VEight at very low temperatures. Another test measures an oil’s ability to prevent wear and resist oxidation and involves running the oil for 64 hours in a 350 c.i. Oldsmobile V-8 at 3000 rpm with sump temperature at 300°. Yet another test monitors ability to prevent valve train wear in a 2300cc Ford Four, an engine notorious for valve train problems and subject to a recall at one point due to premature camshaft wear. The fourth test uses a single cylinder lab engine and tests for main bearing wear—the plain bearings are weighed before and after the test.

The SF rating superseded the SE rating, which required much the same testing but used older engines and had looser pass/fail standards.

Before test procedures or pass/fail criteria are put into use, they are voted on by representatives of oil companies and automotive manufacturers, so it is fair to say that the regulated companies have veto power over the regulations.

Except that they are not really regulations at all. The tests are conducted by the individual oil companies or by testing firms hired by them, and the API, SAE and ASTM have no enforcement powers.

An unscrupulous individual could found an oil company, buy a truckload of grade 30 base stock, package it with no additives and sell it as a super-premium, magic SF 20w-50 oil—at $13.97 a quart—and there’s no guarantee that he’d be stopped. If enough people complained that their engines blew up after switching to the miracle oil, consumer protection agencies in individual states might investigate. Complaints from consumers or from competing oil firms might trigger a probe by the Federal Trade Commission (FTC), but the usual result of an FTC investigation is a consent decree, in which a company doesn’t admit that they’ve done anything but promises not to do it again.

The API does check oil at random to see if it meets the service ratings claimed by the manufacturer. If an API representative bought an SF-labeled oil in a motorcycle shop and tests showed that it did not meet SF requirements, the oil manufacturer would be notified in writing and be asked to supply the results of its own tests. If the company refused to do so or couldn’t justify its SF claim, then the API could forward the information it had collected to state consumer protection departments. Each state’s attorney general could then decide to prosecute the company involved.

However, most large, well-established oil companies are truthful in their product claipis. Any false claim is likely to trigger an expensive lawsuit by a customer or a group of customers. Even suits by individual consumers have the potential of costing a company big money, and a classaction suit involving hundreds or thousands of people claiming an oil ruined their car or motorcycle engine could be a financial disaster.

It is safe to assume, then, that an oil labeled SF and manufactured by a wellknown, long-established, reputable company actually does pass the SF series of tests.

Is there a quality difference between the cheapest SF oil you can buy at a discount auto parts store and the most expensive SF oil sold in motorcycle shops? Maybe, but the most expensive oil might not be the best oil. There is a cost difference between a very good oil, one that far exceeds SF requirements, and an oil that just squeaks past the SF tests, but that difference is in the cost of manufacturing the oil. Better additive packages, bigger additive packages, more shear-resistant polymers all add to the price of making an oil. More expensive additives may deliver more protection against scuffing and wear. And because the shear encountered in a motorcycle transmission lubricated by the engine oil is much more Severe than the shear encountered in any of the engines used for SF rating tests, it is possible that one SF rated oil—with highquality, expensive, polymers—could be very shear resistant while another SF rated oil—one with less expensive polymers—could show extreme shear in a motorcycle engine.

But not all manufacturing costs are related to quality. Making a small quantity of oil increases the per-quart manufacturing cost and making a huge quantity of oil decreases the per-quart manufacturing cost, even if the oils are of identical quality.

Beyond that, retail prices do not always directly reflect manufacturing costs. Some chains of auto parts stores buy truckloads or even trainloads of top quality SF oil—receiving a quantity purchase discount—and sell the oil as a loss leader, charging close to or even less than what the oil cost them. The idea is to get people to come into the store to buy the discounted oil, then sell them other, more profitable items, perhaps oil filters, timing lights or service manuals.

So now what?

SF oils sold by reputable, well-established companies probably really are good oils, and price isn’t necessarily a good indicator of quality.

Assume for a moment that it was easy to look at cans or bottles and tell a very good SF oil from a so-so SF oil. What is the benefit of buying the oil with more and better additives and more shear-resistant polymers?

All SF oils offer at least SF-quality antiwear performance and resistance to shear and oxidation. The big unknown is polymer quality and longevity, (because a motorcycle uses the same oil to lubricate both engine and transmission and transmission gears are hard on polymers), and the amount of anti-oxidation additives.

A low 20w-50 oil with less resilient polymers will shear down into a 20w-40 in fewer miles than an otherwise identical 20w-50 oil with better polymers. An oil with more anti-oxidation additives will resist oxidation—which can turn oil into a black, Jello-like substance—longer than an otherwise identical oil.

As oil temperature increases, shear and oxidation also increase, although, generally, oxidation of an SF-rated oil is not a problem at oil temperatures below 300°.

What is a normal oil temperature for an air-cooled motorcycle engine? Back in December of 1978 Cycle World tested several oil coolers. Those tests included baseline runs without an oil cooler installed. In those tests a KZ1000 Kawasaki carrying two 160-lb. passengers and equipped with a touring fairing, scoot boot, and saddlebags (filled with 50 lbs of cargo) recorded oil temperatures of 180° at a constant 55 mph with a 70° ambient air temperature. Increasing speed to 70 mph with an ambient temperature of 100° brought oil temperature up to 210°. Running the Kawasaki 12 mi. up a mountain pass with an elevation gain of 4000 ft. increased oil temperature from 180° to 234°.

A GS550 run on a racetrack at consistent fast lap times in 80° ambient temperature brought oil temperature up to 272° in just eight laps, from a starting oil temperature of 200°.

Those temperatures were taken from each bike’s oil sump as recorded by digital thermometers.

Those numbers are similar to the results of tests conducted by motorcycle manufacturers. In one test, Honda engineers ran a CB750F and a CB750C on a California freeway, in an ambient temperature of 99°. Oil temperatures ranged from 230° to 248° in the sump. Tests with a CB650, which runs hotter than a CB750, yielded a peak freeway temperature of 275°. Taken to a racetrack and run at high rpm, the same CB650 recorded a peak sump temperature of 338°.

Based on those tests and subsequent engine teardowns of the tested bikes, representatives of American Honda say that peak oil sump temperatures of 284° to 338° are normal and will not present any problems.

Yamaha engineers run peak oil sump temperature tests on an oval road race course in Japan, the banked track allowing a motorcycle to be run continuously at full trottle in top gear. According to a Yamaha engineering department spokesman, normal peak oil temperatures are 302° to 311°, depending upon the model. If an engine develops oil sump temperatures above 311°, Yamaha engineers make changes to bring temperature down, such as adding cooling fins to the crankcases or fitting an oil cooler.

The results of tests by Kawasaki Motors Corp. engineers have convinced them that sump temperatures of 300-325° cause no problems. When a KZ900 set a 24-hour average speed record at Daytona in 1973, oil sump temperatures averaged 350°, and the engine stayed together.

Suzuki engineers tested a GS1100 at the Yatabe test circuit in Japan, running the bike at top speed continuously on the steeply-banked track, and oil temperature reached 320° in the sump. Teardown revealed no problem.

Testing a stock GS1100 at Willow Springs, Team Hammer’s endurance roadracers recorded sump temperatures of 320°, keeping the bike running at that temperature for four hours, with racestyle pit stops for rider changes and quickfill refueling. The engine looked good when it was torn down later.

Kawasaki used SE oils in its tests, and recommends SE oil for its street bikes. Yamaha also recommends SE. Honda and Suzuki test with SF oils and recommend either SE or SF oils, although company spokesmen say that SF oils are better. >

All the temperatures we’ve talked about so far have been taken in the sump. But oil temperature rises as the oil travels through the engine from the sump. To find out how much it rises, Team Hammer fitted temperature sensors into a 1170cc GS1100’s sump, the main oil gallery behind the cylinders (which feeds the crankshaft), the cylinder head gallery feeding the intake rocker arms, and the cylinder head gallery feeding the exhaust rocker arms.

The tests were conducted at Sears Point, a twisty, tight track that didn’t require sustained high rpm from the big-displacement Suzuki racebike. Instead, the bike was geared tall (to control wheelies) and got its good lap times from strong mid-range torque and acceleration off the corners.

In those tests, when sump temperature was 225°, main oil gallery temperatures were 250°. Intake rocker gallery temperatures were also 250°, but exhaust rocker gallery temperatures were 235°, probably due to the cooling air stream first contacting the exhaust side of the cylinder head.

But while those figures are interesting, they don’t answer all the questions, so we conducted some basic tests. Our goal was to find the relationships between rpm and oil temperature as well as oil viscosity and oil temperature.

We fitted a 1980 Honda CB750F with two (one was a spare, but wasn’t needed) Keithley 870 Digital Thermometers (available for $257 from B.J. Wolfe Enterprises, 10769 Burbank Blvd., North Hollywood, Calif. 91601). The Keithley thermometers can read temperatures in centigrade or Fahrenheit on scales of 0-200° or 0-2000° with a manufacturer’s claimed accuracy of ±1°. We positioned the temperature sender in the main oil gallery behind the cylinders, which feeds the crankshaft, and set the tank-mounted thermometers to read 0-2000°F. Because the thermometers have large LCD numbers, they’re easy to read.

Technical editor Steve Anderson rode the test bike on a 35.9 mi. loop of remote freeway and logged temperature readings on a white card taped to the bike’s gas tank. The readings were taken at geographic landmarks located at 7 mi. intervals on the loop. The freeway used always has at least four lanes in each direction, so Anderson could maneuver around any traffic encountered without changing speed (or engine rpm).

Over the course of two days we made nine trips around the test loop, each one taking about 40 min. including time from the residential garage used as a base to the freeway. Weather was overcast, keeping ambient air temperatures fairly constant.

For test purposes we picked up five cases of oil, one case each of Spectro-4 10w-40; Spectro-4 20w-50; Bel-Ray EXP 10w-40; Bel-Ray EXP 20w-50 and BelRay Racing 40.

The first step in the test was to warm up the bike and drain the oil. The filter cover and drain plug were replaced and the cases filled with exactly 3.5 qt. of Spectro 10w-40. Then the bike was run at 2000 rpm for three minutes, the oil drained, a new oil filter installed, another 3.5 qt. of new Spectro 10w-40 put in the cases.

The extra change flushed out any of the original oil still in the engine, thus ensuring the tested oil wasn’t contaminated.

On the freeway, Anderson held the bike at a constant 7100 rpm, about 65 mph, in third gear.

The bike’s oil temperature reached 223° at the first checkpoint, followed by readings of 270°, 292°, 298° and 300° at the other checkpoints.

Back in the garage, the Spectro 10w-40 was drained, the bike flushed out with 3.5 qt. of Spectro 20w-50, the oil filter replaced and the bike refilled with 3.5 qt. Spectro 20w-50.

On the second loop we recorded oil temperature at the start, something we hadn’t done the first time, and it was 161 °. At the first check, temperature had risen to 254°, followed by readings of 286°, 301°, 298° and 300°.

Back at the garage we repeated the drain, fill, drain, fill sequence and switched back to Spectro 10w-40. Oil temperature at the start of the third loop was 176°. At the first checkpoint, temperature was 243°, followed by readings of 279°, 298°, 299° and 298°.

For the fourth loop, we installed an oil cooler and started with an oil temperature of 188°. At the first checkpoint oil temperature was 237°. The second and third checkpoint readings were 256° and 267°. At the third checkpoint, Anderson clicked the Honda into fifth gear at the same road speed (5000 rpm at 65 mph), and oil temperature dropped to 236° at the fourth checkpoint and 225° at the fifth.

So much for day one. We were puzzled by two things: The differences in oil temperature readings encountered on the different test runs, and the drop in temperature readings sometimes seen for check* points four and five.

It was easy enough to explain the checkpoint four and five readings—the loop was uphill until checkpoint three, then downhill, and downhills require less throttle. As far as the differences in temperatures at checkpoints for different runs, maybe & had something to do with oil temperature at the start. So, for day two, we controlled the starting oil temperature, beginning each run with the temperature at 165°. If the temperature was too high, we turned off the engine and cooled it with floor fans. If the temperature was too low, we ran the parked bike at 2000 rpm until oil temperature came up to 165°. We also recorded ambient temperature at the start and end of each run, taking readings from a photo chemical control thermometer calibrated in 1 ° increments and capable of responding to temperature changes in one minute.

We also decided to run the bike at normal freeway speed and rpm; 62.5 mph, and 4800 rpm.

The first run of day two used Spectro 10w-40 and no cooler. Readings at the five checkpoints were 207°, 223°, 234°, 232° and 226°. Ambient at the start of the loop was 65°, at the end, 65°.

Run two used Bel-Ray 20w-50, with readings of 206°, 224°, 234°, 229° and 225°. Ambient at the start was 68°, ambient at the finish, 70°.

Run three used Bel-Ray 10w-40 with readings of 206°, 224°, 236°, 230°, and 226°. Ambient started at 71° and ended at 72°F.

Run four used Bel-Ray 20w-50 witH readings of 206°, 226°, 238°, 233° and 228°. Ambient at the start was 70.5°, and the finish, 72.5°.

Run five used Bel-Ray Racing 40, with readings of 205°, 226°, 240°, 231° and 226°. Ambient started at 68° and ended at 66.5°.

The results showed that, given the same starting oil temperature, the same quantity of oil in the engine, and the same steady rpm over the same road, oil viscosity does not have a significant effect on oil temperatures.

The effect of ambient temperature less clear, except that ambient temperature clearly does not have a one-to-one linear effect on oil temperatures. That is, a rise of 1 ° ambient does not produce a rise of 1 ° in oil temperature. This fits in nicely with the opinion of a heat transfer engineer (involved in cruise missile engine design) who told us that ambient air temperature has a fractional effect on oil temperatures. That is, a rise of 10 ambient increases oil temperature a fraction of 1 °, possibly somewhere between 0.25° and 0.5°.

It’s important in these discussions to remember that oil temperature rises as fuel consumption increases, and that time is as important as temperature

Motorcycles run hotter on the racetrack than on the street because they are kept at higher rpm, burning more fuel and making more power.

And while running a motorcycle at 320° sump temperature for four hours (about 360 mi. at Willow) might be fine, running the same bike at 320° sump temperature for 55.5 hours (about 5000 mi. at Willow) could shear the oil down enough to allow metal-to-metal contact and catastrophic mechanical failure, or—depending upon the shear resistance and antioxidation additives—turn the oil into nonflowing black goo with the same bad results.

We know that shear and oxidation increase as temperature rises. We know that SF rating tests include running 64 hours (about 5800 mi. at racing speed at Willow, about 2600 mi. at an average street speed of 40 mph) with a sump temperature of 300°.

We know that oil temperature increases with fuel consumption, that continuous high-rpm running dramatically increases oil temperature, and that it takes extreme conditions to bring an average street bike’s oil temperature up to 300°.

Knowing all that, it’s possible to reach basic conclusions. Working backwards, motorcycles ridden normally on the street will be just fine and last a long time using SF-rated oil changed at the manufacturer’s recommended interval. Motorcycles ridden hard enough, at high enough rpm, to bring oil temperature over 300° make greater demands on their oil in terms of shear and oxidation. The more time the oil temperature stays at or over 300°, the more shear and oxidation resistance is required, and given enough time over 300°, even very good SF oils can break down.

A motorcyclist worried about his engine’s oil because it runs above 300° can do two things: A) Use SF 20w-50 (or l0w-50, or 15w-50, as long as the 210° rating is SAE grade 50) because it has superior film strength at higher temperatures and because if it does shear down, it will shear down into a 20w-40 (or 10w-40 or 1 5w-40) and probably still provide adequate film strength; and B) change the oil more frequently.

How frequently? We posed a hypothetical question to several oil company technicians. Asuming they owned a highperformance motorcycle that routinely reached 300° sump temperature, we asked, what weight and grade oil would they run and how often would they change it?

Some of the oil company representatives pushed their own company’s product heavily, claiming that the key to Lubrication Nirvana was to buy and use their oil. But all agreed they’d run an SF-rated 20w-50, and every technician who didn’t take a commercial stance, who didn’t talk in specific “buy ours” terms but instead offered general, widely-applicable information, said they’d change the oil more frequently than the motorcycle manufacturer recommended, at 1000 or 1500 mi. intervals, and that they’d change the filter at the same time.

That’s on the street. Racebikes, even stock-production machines, should have fresh oil before every raceday, especially if sump temperatures stay at 310°-320° and above.

That seems reasonable. No harm can come from changing oil and oil filters frequently, or from using oil with the highest available (SF) API service rating.

But what of the rider who can’t be bothered, or doesn’t know? Well, one of the best things about modern motorcycles is that they survive abuse. Besides cases when owners didn’t keep an eye on the oil level and ran their bike without enough (or any) oil, lubrication-related failures are rare. Freeways aren’t littered with motorcycles that blew up because somebody didn’t change the oil often enough; service departments aren’t overflowing with engines that broke because somebody didn’t use the best possible oil.

So don’t panic.

Everything’s going to be all right.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontAdvice To the Lovelorn

October 1982 By Allan Girdler -

Letters

LettersLetters

October 1982 -

Departments

DepartmentsRoundup

October 1982 -

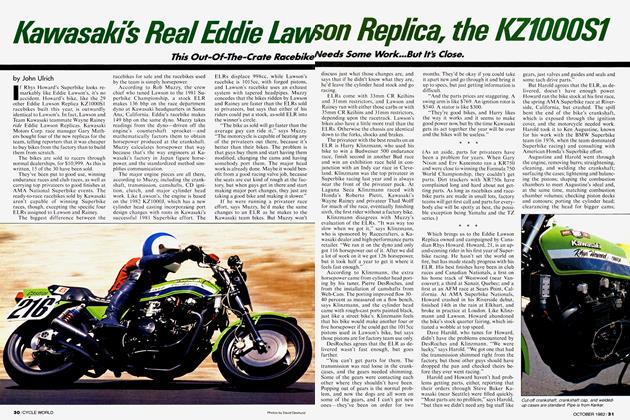

Competition

CompetitionKawasaki's Real Eddie Law Son Replica, the Kz1000s1

October 1982 By John Ulrich -

Features

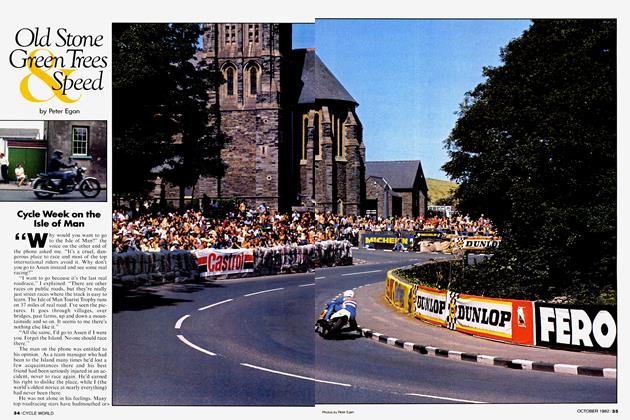

FeaturesOld Stone Green Trees & Speed

October 1982 By Peter Egan -

Evaluation

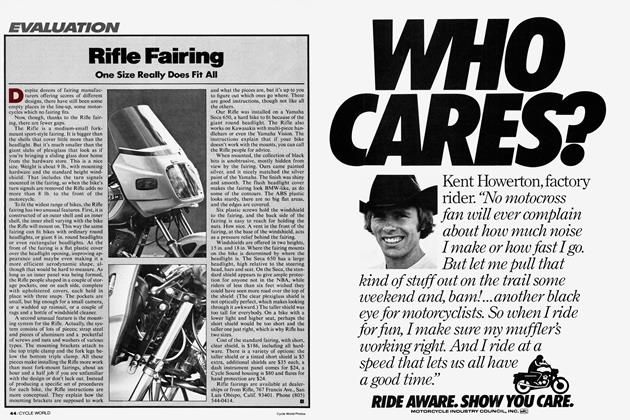

EvaluationRifle Fairing

October 1982

Current subscribers can access the complete Cycle World magazine archive Register Now

John Ulrich

-

Departments

DepartmentsCycle World Book Reviews

DECEMBER 1983 By Allan Girdler, John Ulrich -

Competition

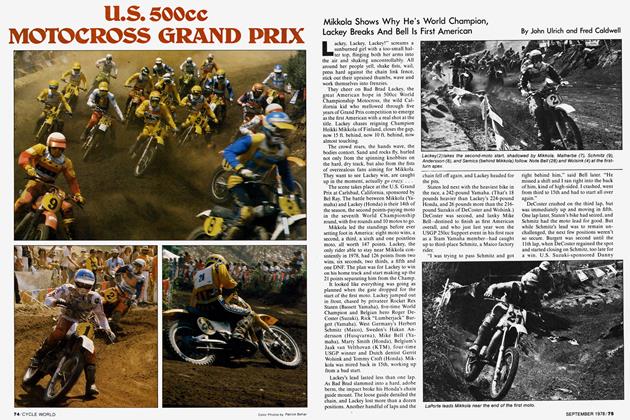

CompetitionMikkola Shows Why He's World Champion, Lackey Breaks And Bell Is First American

SEPTEMBER 1978 By Fred Caldwell, John Ulrich -

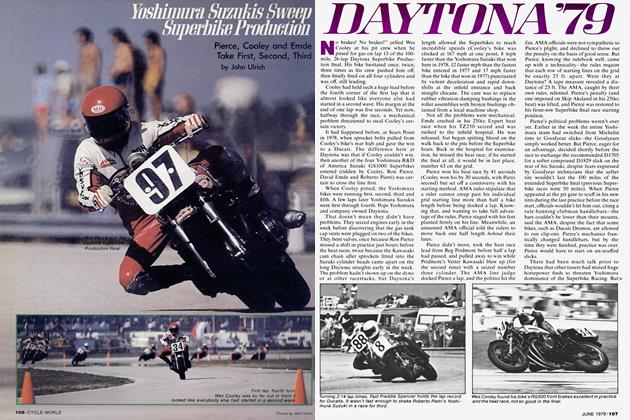

Yoshimura Suzukis Sweep Superbike Production

Yoshimura Suzukis Sweep Superbike ProductionYoshimura Suzukis Sweep Superbike Production

JUNE 1979 By John Ulrich