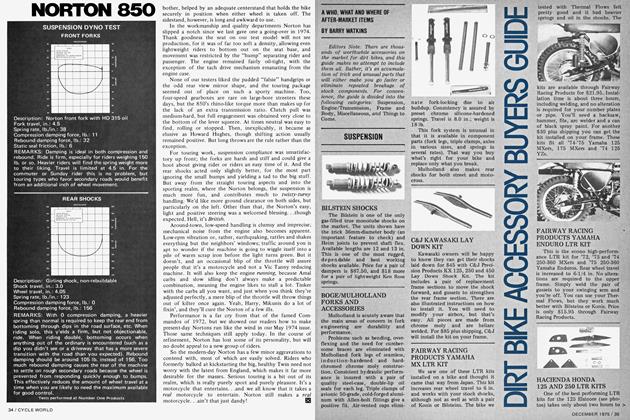

THE SERVICE DEPT

Barry Watkins

YAMAHA PRODUCTION MONOSHOCK AND YZ UPDATE

Remember when the Yamaha YZ Monoshock made its debut late in ’74? At that time, it was very close to being the best production motocrosser ever made. But times have changed. Longtravel suspension is commonplace now, as are more powerful engines. Steering geometry has improved some too.

Yamaha recognized this and incorporated most of the latest design thought into its 1976C model, but that does nothing to help original Monoshock purchasers. . .purchasers whose mounts have become outdated all too quickly.

If you have a 250cc ’*74 or ’75 YZ, or a ’75 production Monoshock, the following definition of problems and solutions should interest you. (Frame and fork fixes will also work on big-bore Monoshocks).

PROBLEMS

1. Excessive weight. Both YZ and production Monoshocks simply weigh too much. They are 15 to 20 pounds heavier than the competition, and this hurts in both acceleration and braking.

2. Insufficient power. Power is adequate on the production MX, but not in the right place. The early YZ needs more horsepower but has nice torque. Either way, you lose.

3. Weak frame. This is particularly true of production versions. In spite of the production frame’s 29-lb. weight, we have heard of a few desert riders breaking them at the rear frame section.

4. Poor front forks. The 35mm stanchion tubes flex too much under severe cornering loads or when the bike lands from a high-speed jump.

5. Poorly tuned Monoshock unit. The 250/360 YZ monoshockers suffered from too little rebound damping, which caused the rear suspension to bounce (top) excessively. On the 400 production MX, Yamaha overcompensated with excessive return damping; and on long straights with whoopies, available rear wheel travel diminished as the Monoshock unit packed down.

6. Poor tires. Especially true on the front. You can corner about as well on a D.I.D. rim as you can on factory rubber.

7. Restrictive air cleaner. The stock foam units simply don’t let the engine breathe enough air.

SOLUTIONS

A lot needs to be done, but costs are moderate for several of the modifications.

For example, your engine will breathe much better if you simply replace the stock air filters with a pair of K&Ns. You won’t believe the difference. . .and the new filters only cost about $ 12.

Another inexpensive modification is replacement of the 13-tooth countershaft sprocket on YZ models with a 14-tooth sprocket. The 13-tooth unit provides too much wheelspin. 250s in particular are just as quick with a 14-tooth, have more top speed, and are easier to ride. Cost is in the neighborhood of $5.

The next change costs some bucks but produces by far the biggest performance increase. On our 250, we switched to a 38mm Mikuni carburetor. If properly jetted, this carb eliminates the bog at low revs and increases power through both mid-range and top-end. The 250 production motocrossers come with 38mm Mikunis, so if you have one, you’re about $52 ahead of the guys who own YZs.

(Continued on page 92)

Continued from page 64

Proper jetting will vary with altitude, but the following will be close, especially if you ride from sea level to 3000

feet.

Both the YZ and production Monoshock expansion chambers have the same dimensions and are good. We don’t think the expense of a new pipe is worthwhile.

Porting is basically the same on YZ and production 250s. The production version, however, has a cast iron liner instead of hard chromed aluminum (my preference to the latter for all-out performance). The production barrel also has transfer slots in the base that theoretically improve the mixture of the incoming fuel charge. This is a very difficult porting operation to duplicate on a chrome cylinder, so we decided the risk of ruining a YZ cylinder was not worth this modification.

We did have Fairway Racing Products blueprint the cylinder to factory specifications. The only object here is to eliminate production tolerances from the dimensions and to clean up the ports.

Both YZ and production Monoshock owners need not change the cylinder head, as overheating is not a problem on either engine.

For less than $70, we have substantially improved power. Now let’s see what can be done for the suspension and chassis.

First, we removed the stock front tire and made a special trip to the junkyard to be rid of it. One of the best all-around replacements available is the 3.00-21 Metzeler motocross tire. We installed that. We couldn’t find a Metzeler for the rear, so we settled for a Yokohama 4.60-18 Dirt Digger. Cost of both tires is $60-70. Change the front tire immediately. The stock rear will do until it wears out.

If you plan to race your Monoshock seriously, you’ll have to solve the fork problem. The best cure is very expensive. . .like around $350. For that price, you can substitute your wobbly fork setup for a Wheelsmith Engineering 8.75-in. travel Maico front end. Benefits (Continued on page 94) are pinpoint steering, a plush ride and total elimination of fork flex.

Continued from page 92

For motocrossers, Greg Smith recommends the new heavy-duty Maico stanchion tubes made from chrome-moly tubing. The Maico forks with the axle position ahead of the lower fork tube provide positive trail and good control even at maximum compression. No other fork design has this feature.

Damping characteristics were developed on Kawasaki’s shock dyno. The fork kit increases travel about 1.5 in. over the new stock Maico forks and about 2.5 in. over the old Maico forks, (it is cheaper to buy a set of old Maico forks at the swap meet and have Wheelsmith install the kit). You will need about 260cc of Bel-Ray 20or 30-wt. fork oil. Wheelsmith’s kit goes for about $65 installed, including springs. They must install the kit, as the extensions are heliarc welded to the fork sliders. Springs with fewer windings are necessary to prevent coil binding when the travel increases. The reason this kit is desirable is that it achieves the extra travel with an extension below the axle, and this means chassis geometry is not changed from stock.

Keep in mind that the above modifications are so expensive that we would only recommend them for serious motocrossers. You’ll also have to modify the bottom Maico fork crown to accept the Yamaha fork stem, but Wheelsmith can perform the modification.

Desert riders who don’t care about precise cornering can extend the stock forks for more travel and alter the damping with another damper rod. Terry Industries makes good kits for this. So does Number One Products. Both kits are reasonably priced.

Now it’s time to focus on that much acclaimed and potentially fantastic 9.5-lb. Monoshock unit. Yamaha’s YZ units were treacherous when cornering on washboard surfaces because there was a lack of rebound damping. Yamaha’s cure with the 400 MX was to go the other way and give excessive rebound damping. On this model, available travel decreased when a series of bumps was encountered because the shock could not return to its fully extended position quickly enough.

Fortunately, both problems can be easily cured. There are at least two companies we know of that are successfully modifying Yamaha Monoshocks. One is Orange County Cycle and the other is Fairway Racing Products. Regardless of who performs the modification, you must ask yourself how you want the unit to perform, based on what kind of riding you do.

(Continued on page 98)

Continued from page 94

There are four basic variables to consider in tuning the Monoshock. They are: oil viscosity, spring rate, damping rate and nitrogen pressure. The trick is to select the proper oil and spring rate so that you only have to experiment with one or two variables.

So far, Bel-Ray LT300 oil has worked best. Yamaha now has about five different springs available and you should be able to tell whether yours is correct, too stiff, or too light. Make the correction.

The rebound orifice size in the piston is the trickiest modification. Altering from stock requires special tools and some knowledge about the Monoshock unit itself. If you tell the truth about your riding ability, either company mentioned above can perform the modification successfully.

Assuming the above-mentioned characteristics are correct, the nitrogen pressure must be determined. Our unit ended up with 330 psi. The rider involved is a 145-lb. Expert. I preferred the gas at about 290 psi, even though my weight was 50 lb. more. In general, the faster you ride and the more you weigh, the more pressure you need. Again, Orange County Cycle or Fairway can come close if you are honest about your ability.

Orange County Cycle will disassemble your shock, clean the parts, check the wave washers adjacent to the O-ring, install their piston, replace the oil with Bel Ray FT300, Foc-Tite and safety pin the nut at the end of the main shaft, reassemble the unit, and wrap the seal housing with tape to keep it from vibrating loose. All of this totals $54.86, including a spring if necessary.

Fairway Racing Products' piston costs $5.95. For another $24 they will change the oil, rework and install their valve and reassemble the shock.

Once revised, the Monoshock is smoother over little ripply bumps and works great at high speed. Traction through corners is markedly improved because the wheel stays on the ground where it belongs.

For weekend racing or just plain riding for fun, altering the suspension and engine as we have suggested is all you need. Your bike will be faster and easier to ride than when it was stock. And it won’t tire you out as much because the suspension will be doing more of the work.

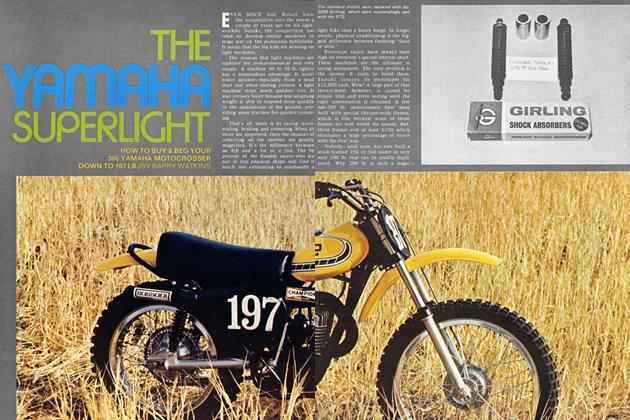

Serious racers still have one problem to overcome: weight. Unfortunately,

frame replacement is the only solution. For details, see “The Service Dept.” next month. 0